Mod Guide: Induction and Exhaust (PLEASE READ BEFORE POSTING)

#1

Preface:

The LS1 like any other engine works as a system, treat is as one, you want to get as much air in and out as you can. The plethora of mods out there will allow you to do that. Things to consider before you start on your modding process:

1) There is no "best" part when it comes to mods.

2) When you want to start modding your car come up with a tangible plan.

3) Do not go into modding blindly; you will end up wasting money, time, and effort.

4) Do your research before you buy mods.

5) Find out your states/counties emissions requirements before choosing mods

6) Be realistic on what your going to do with your car

7) Usable power under the curve is what you want to shoot for, do not just look at peak gains

8) Work within your budget

9) If your are still under warranty Contact your own dealership and discuss your warranty and modding issues.

(Credit given where applicable. Info/pics taken from personal experience, around the Internet, and ls1tech/ls2.com)

II Exhaust

A. Catbacks

What they are: Bassani Borla Corsa Hooker Magnaflow Random Tech Loud Mouth LM w/ quad tip center mount SLP Dual/Dual GMMG Mufflex

What they do: increase exhaust flow and alter sound

What to look for: depends on what kind of look and sound your going for. The premier ls1 sounds site here. Spend alot of time listening to the setups and hear as many setups in person as you can. Exhaust is subjective, so get what you like best in terms of sound since its you who are going to be driving the car around.

- Straight through setups like LM and magnaflow (pt# 14267 for just the muffler) are regarded as some of the top flowing catbacks. Flowmaster is one of the worst flowing catbacks for the LS1, it does sound good in its defense. Hooker, Magnaflow, SLP D/D are all great budget cat backs; Corsa, Borla, and GMMG round out the top of the premium spectrum.

- Loudmouth: LM is a love/hate exhaust, it sounds great on stock manifolds with few bolts on's. When you start adding LT's and ORY's it shows its ugly side. LM + ORY + LT = rasp and drone. Try and listen to various LM setups in person to know what your getting into. Time after time people get LM and end up swapping it out since they get tired of its annoyances. To reduce the rasp and drone you have a few options; install some cats, replace the resonator with a real muffler, or install a 12-18" dynomax bullet. This setup is referred to Dynomouth; Borlamouth is of the same concept but with Borla xr-1 mufflers.

- With the Introduction of the TSP Rumber you no longer have to hack up your LM as the system is basically dynomouth. (Pic 2)

How to install: Follow the instructions that came with the setup. Some tips:

- Use pipe cutters or a sawz-all to remove the old exhaust, cut at the over the axel pipe or muffler.

- A breaker bar comes in very handy, some of those old bolts and clamps are alot harder to get off then you think

- Use alot of penetrating oil (i.e WD40)

B. Headers

What they are: there are 3 styles of headers for the ls1:

1) Shorties: Easy to install, small power gain

2) Mid-length: Not too small, but not so long as to scrape if your car is lowered

3) Long-tube: Biggest and best. Will maximize power as well as exhaust noise

What they do: allow that great engine of an ls1 breath

What to look for:

- Decide which header is right for you. If you want to stay 100% smog legal you'll need to stay with Shorties only and make sure they have a CARB number.

- If you have an 00-02 car do not bother with shorties. They received a better-designed manifold and flow quite well actually for what they are. You will see minimal gain if any by switching to shorties. If you have a 98-99 car you'll gain some rwhp from shorties but it wont be much either.

- If you decide on shorties work your other mods around that aspect meaning if you decide for a future cam keep it small (220 duration or smaller).

- ANY headers besides shorties will require a new Y pipe.

- Mac Mid-lengths vs LT's. The whole Mid vs LT debate will continue to go on, I’ve learned macs can produce great numbers and are a viable option for alot of people. Mac makes headers for 98-99 and 01-02 cars; if you have an 00 car you will need the EGR pipes from a 98-99 car or you'll need to remove your EGR system.

-Macs and QTP LT’s side by side.

- When buying long tubes what you are paying for is fitment, quality, fit and finish. All LT's dyno within the same net gain. Swap from one brand to another for the sole purpose of gains and you'll be disappointed. 1 3/4 sized primaries are more then adequate for stock cubes. If you have a stroker look into some 1 7/8 primaried headers. If you have a high power stock cubed setup you might want to look into a 1 ¾ stepped to 1 7/8.

- Buy your headers with some kind of ceramic coating or get stainless steel. If you cant afford coated headers hold off until you can. If your car see's alot of winters (real winters; i.e. east coast and mid west, ect) you might want to seriously consider the stainless steel headers, they are more expensive then ceramic coated headers but the chance of rust will be greatly diminished.

- If you plan to lower or are lowered then any long tube other then SLP will tuck pretty nicely.

Long Tubes

Since Long Tubes are by far the most popular headers they receive the most questions; to a certain extent the old adage of "You get what you pay for" rings true. Info on a few of the more popular choices, not all the long tubes available by no means.

Pacesetters: Extremely popular due to there price, coated they can be had for under 400 dollars. Quality is very good for what your spending your money on, welds and collector are good. If you’re on a budget and want LT's then Pacesetters should be at the top of your list. Mid production cycle Pacesetter improved on some of the fitment issues people were having with the k-member and banging.

Jet Hot/Hookers: The Hooker and Jet Hot Long Tubes are of the same design, jet hot took the hooker design and improved upon it a bit by moving the o2 bungs on the inside of the headers and they use a thicker tubing and have thicker flanges. Both are great long tubes and will run you 500-600 bucks.

QTP/kooks: Both Kooks and QTP are stainless steel headers, and are generally regarded as the cream of the crop. Quality is top notch and they can be polished for that bling look if you'd like. There only draw back is the price, at 700+ they are not for everyone. If you have the money or are the kind of person who wants the best then kooks or qtp is what you want. As far as kooks vs qtp get whichever one is cheaper.

SLP: SLP's are the long tube that usually sparks some debate. Alot of newbies are drawn into them because of the hp claims slp makes. But as already stated all LT's dyno within the same range so SLP's claims are moot. From a quality stand point they are a great header; stainless steel and are ceramic coated. There major drawback is installation and there ground clearance, or lack there of. If you plan to lower your car then pass on the SLP's or learn to change your driving style or else you'll endure alot of scrapping. Another drawback is the price as they are 700+. (My personal opinion, if you’re going to spend 700+ on headers then go for the kooks/qtp)

The LS1 like any other engine works as a system, treat is as one, you want to get as much air in and out as you can. The plethora of mods out there will allow you to do that. Things to consider before you start on your modding process:

1) There is no "best" part when it comes to mods.

2) When you want to start modding your car come up with a tangible plan.

3) Do not go into modding blindly; you will end up wasting money, time, and effort.

4) Do your research before you buy mods.

5) Find out your states/counties emissions requirements before choosing mods

6) Be realistic on what your going to do with your car

7) Usable power under the curve is what you want to shoot for, do not just look at peak gains

8) Work within your budget

9) If your are still under warranty Contact your own dealership and discuss your warranty and modding issues.

(Credit given where applicable. Info/pics taken from personal experience, around the Internet, and ls1tech/ls2.com)

II Exhaust

A. Catbacks

What they are: Bassani Borla Corsa Hooker Magnaflow Random Tech Loud Mouth LM w/ quad tip center mount SLP Dual/Dual GMMG Mufflex

What they do: increase exhaust flow and alter sound

What to look for: depends on what kind of look and sound your going for. The premier ls1 sounds site here. Spend alot of time listening to the setups and hear as many setups in person as you can. Exhaust is subjective, so get what you like best in terms of sound since its you who are going to be driving the car around.

- Straight through setups like LM and magnaflow (pt# 14267 for just the muffler) are regarded as some of the top flowing catbacks. Flowmaster is one of the worst flowing catbacks for the LS1, it does sound good in its defense. Hooker, Magnaflow, SLP D/D are all great budget cat backs; Corsa, Borla, and GMMG round out the top of the premium spectrum.

- Loudmouth: LM is a love/hate exhaust, it sounds great on stock manifolds with few bolts on's. When you start adding LT's and ORY's it shows its ugly side. LM + ORY + LT = rasp and drone. Try and listen to various LM setups in person to know what your getting into. Time after time people get LM and end up swapping it out since they get tired of its annoyances. To reduce the rasp and drone you have a few options; install some cats, replace the resonator with a real muffler, or install a 12-18" dynomax bullet. This setup is referred to Dynomouth; Borlamouth is of the same concept but with Borla xr-1 mufflers.

- With the Introduction of the TSP Rumber you no longer have to hack up your LM as the system is basically dynomouth. (Pic 2)

How to install: Follow the instructions that came with the setup. Some tips:

- Use pipe cutters or a sawz-all to remove the old exhaust, cut at the over the axel pipe or muffler.

- A breaker bar comes in very handy, some of those old bolts and clamps are alot harder to get off then you think

- Use alot of penetrating oil (i.e WD40)

B. Headers

What they are: there are 3 styles of headers for the ls1:

1) Shorties: Easy to install, small power gain

2) Mid-length: Not too small, but not so long as to scrape if your car is lowered

3) Long-tube: Biggest and best. Will maximize power as well as exhaust noise

What they do: allow that great engine of an ls1 breath

What to look for:

- Decide which header is right for you. If you want to stay 100% smog legal you'll need to stay with Shorties only and make sure they have a CARB number.

- If you have an 00-02 car do not bother with shorties. They received a better-designed manifold and flow quite well actually for what they are. You will see minimal gain if any by switching to shorties. If you have a 98-99 car you'll gain some rwhp from shorties but it wont be much either.

- If you decide on shorties work your other mods around that aspect meaning if you decide for a future cam keep it small (220 duration or smaller).

- ANY headers besides shorties will require a new Y pipe.

- Mac Mid-lengths vs LT's. The whole Mid vs LT debate will continue to go on, I’ve learned macs can produce great numbers and are a viable option for alot of people. Mac makes headers for 98-99 and 01-02 cars; if you have an 00 car you will need the EGR pipes from a 98-99 car or you'll need to remove your EGR system.

-Macs and QTP LT’s side by side.

- When buying long tubes what you are paying for is fitment, quality, fit and finish. All LT's dyno within the same net gain. Swap from one brand to another for the sole purpose of gains and you'll be disappointed. 1 3/4 sized primaries are more then adequate for stock cubes. If you have a stroker look into some 1 7/8 primaried headers. If you have a high power stock cubed setup you might want to look into a 1 ¾ stepped to 1 7/8.

- Buy your headers with some kind of ceramic coating or get stainless steel. If you cant afford coated headers hold off until you can. If your car see's alot of winters (real winters; i.e. east coast and mid west, ect) you might want to seriously consider the stainless steel headers, they are more expensive then ceramic coated headers but the chance of rust will be greatly diminished.

- If you plan to lower or are lowered then any long tube other then SLP will tuck pretty nicely.

Long Tubes

Since Long Tubes are by far the most popular headers they receive the most questions; to a certain extent the old adage of "You get what you pay for" rings true. Info on a few of the more popular choices, not all the long tubes available by no means.

Pacesetters: Extremely popular due to there price, coated they can be had for under 400 dollars. Quality is very good for what your spending your money on, welds and collector are good. If you’re on a budget and want LT's then Pacesetters should be at the top of your list. Mid production cycle Pacesetter improved on some of the fitment issues people were having with the k-member and banging.

Jet Hot/Hookers: The Hooker and Jet Hot Long Tubes are of the same design, jet hot took the hooker design and improved upon it a bit by moving the o2 bungs on the inside of the headers and they use a thicker tubing and have thicker flanges. Both are great long tubes and will run you 500-600 bucks.

QTP/kooks: Both Kooks and QTP are stainless steel headers, and are generally regarded as the cream of the crop. Quality is top notch and they can be polished for that bling look if you'd like. There only draw back is the price, at 700+ they are not for everyone. If you have the money or are the kind of person who wants the best then kooks or qtp is what you want. As far as kooks vs qtp get whichever one is cheaper.

SLP: SLP's are the long tube that usually sparks some debate. Alot of newbies are drawn into them because of the hp claims slp makes. But as already stated all LT's dyno within the same range so SLP's claims are moot. From a quality stand point they are a great header; stainless steel and are ceramic coated. There major drawback is installation and there ground clearance, or lack there of. If you plan to lower your car then pass on the SLP's or learn to change your driving style or else you'll endure alot of scrapping. Another drawback is the price as they are 700+. (My personal opinion, if you’re going to spend 700+ on headers then go for the kooks/qtp)

Last edited by jrp; 05-28-2005 at 06:18 PM.

#2

FLP: At first glance alot of people are turned off on the FLP setup because of the price. What you have to understand is the FLP setup comes as a kit with the ceramic-coated headers, Y pipe, cats, and off road pipes. When you look at it from that perspective it’s a great deal and setup. The biggest advance the FLP system has is the ability to swap from cats to off road pipes and vise versa at will. Great for guys who want to run off-road pipes and then need to swap to cats for emissions requirements.

Flowtech: When engeneering the Flowtech headers the premise was to build a Hooker set using half the budget; it shows. The welds, and flanges are very thin and the primaries have a dent in them to “clear” the k-member. Even with the “clearance dent” people are still having issues. Because of the low quality TPS has stopped carrying the Flowtech line of LT”s. If you need a budget header look into the new Pacesetter design or spend the dough on hooker/jet hots.

Others available but not reviewed:

-Thunder Racing Headers

-Dynatech

-Stainless Works

-PPC

-SuperMaxx

-TTS

How to install: Flat out, install will vary from car to car and from the type of header you choose, some are easier to install then others.

- Great Pacesetter install guide done by foff667

- SLP guide (done by bomax if i recall)

- Mac Mid's Guide

- Awesome writeup by DirtyJohn! QTP LT's + TSP duals: Install and review.

A few install tips:

- Patience; if after working for several hours without any apparent results take a break. Things often have a way of working out coming back from a fresh start.

- A breaker bar is your friend.

- All LT's go in from the bottom.

- The stock cat bolts will often break, especially on the older 98-99 cars, don’t worry about it.

- Use plenty of penetrating oil on all the cat to manifold bolts.

- Have a buddy/wife/gf help you out when need be.

- Remove the oil diverter for a bit more room on the drivers side install.

- May or may not have to knotch the K-member and floor board clearance (CamaroCain).

- Steering shaft removal may or may not be required. (For my install I couldn’t get the damn thing to budge, so I used a die grinder to grind down the block tab to get the drivers side header to slide up). Heed the warning on the steering shaft before removal.

- Have all the proper tools before the outset of installation; jack/jack stands and/or ramps, basic hand tools (3/8, 1/2 drive ratchet, 10mm, 12mm, 15mm, ect sockets), hammer. Optional but very handy tools that may or may not be needed; sawz-all, die grinder, 2x4 4x4 pieces of wood and/or some bricks.

- Get the car as high as safely possible. It's alot higher then you think. (During my own install I had the rear on ramps and the front was propped up with my jack on a 4x4 piece of wood to get the extra clearance need.)

- Don’t think it has to be mentioned but I’ll say it anyway; use safety goggles where applicable and make sure your car is secured on the ramp/jack stands before getting under the car and working on it. Basically don’t do any stupid ****

- Give yourself plenty of time to get the install done; first time around factor in 5-12hrs. Don’t worry if it takes you longer, just concentrate on getting it done right and gaining the experience

- Typical prices a shop will charge for an install are 300-500 dollars depending on location. If you have the time, you owe it to yourself to give the install a shot yourself. It’s not that hard and doesn’t require alot of technical knowledge or experience. If you run into trouble during the install come to the boards in a calm and collected manner and you'll get your answer in no time.

- Will you need tuning after headers: Every car varies, you wont know until the headers are installed and you've put some miles on the car. Headers usually cause the car to run a bit rich but its nothing stock tune cant handle. If you want full advantage of the new headers then you'll want a tune. Just plan accordingly; if you know your not going to install big mods (h/c) sometime in the near future then I’d go ahead and get a tune. If you plan for a new cam and/or heads then hold off on tuning for the headers and get a tune once the h/c is installed, it'll save you the time and money of having to tune twice. If you don’t want to pay for a full tune you can always pick up a used MAFT (mass air fuel translator) and dial in your A/F ratio a bit.

- Where to buy:

1) Pacesetters: TSP (http://www.texas-speed.com) has the best deals on pacesetters. And they are the only place to get the TSP Rumbler catback and dual setup

2) Kooks: Contact Matt from TTP (http://www.ttperformance.net/) you'll usually get the best deal from him.

3) Jet hot/hookers: Go to the sponsor forums, every so often there is a GP (group purchase) on jet hots and you can get a great price.

4) QTP: Contact Barry from QTP (http://www.quicktimeperformance.com/) and see what kind of price he can get you.

C. Y-Pipes

What they are: Jet hot catted/ory SLP stock replacement Y Mufflex Random Tech stock replacement catted Y Pacesetter ORY

- Catted Y denotes a Y with cats; ORY denotes a Y with no cats

What they do: Connect the headers to the catback and aid in exhaust flow provided it matches the rest of your system. Meaning keep the diameter relatively consistent, 3" is the most popular, a 2.5" is fine as well and will give you a bit more clearance if your lowered.

What to look for: Y pipes come in all different shapes and diameters, if you can, get the Y made by the same company that you got your headers from. Meaning if you get the Hooker LT's then get the hooker Y, ect. All Y pipes are not directly swappable. If you wish to use another manufactures Y for your setup you are most likely going to have to modify it to fit.

-Those looking to get Pacesetters; there Y is a toss up, some people's are "acceptable", others are straight ****. Pace didn’t put to much time or development into making a quality Y and it shows in the collector. Your best bet is to go with a custom Y or modify your Pace ORY like Larry did.

Those with Hooker/Jethot/Pacesetters can now rejoice, TSP has just come out with a 3” Catted Y pipe to fit your headers. They use high flow carsound cats. At 350 a pop you can rest assure that this is the Y-pipe you want to get. They also offer an ORY as well.

- A custom Y is great since its taylored to your exact setup and will allow you to get the best fitment and clearance. Just pick up a Flowmaster merge collector and cats if you need and have a shop fab up the rest; depending on shop it should run you 100-200 bucks not including parts (i.e. merge collector)

- Do Not invest in a new Y pipe unless you plan to stick with shorties/stock manifolds, and even at that it’s barely worth it since you'll gain practically nothing by a new Y on stock manifolds. If you buy a new Y for stock manifolds/shorties you'll need to replace the Y you just bought if you add LT's or mids in the future.

- If you need cats for emissions purposes then do not purchase an ORY and then try and weld cats in them, just spring for the catted Y or purchase some cats, flowmaster merge collector and have a shop fab the rest. Alot of ORY's don’t have enough room to accommodate cats. If you still want to try it then get the smallest cats you can; slp's or random tech.

- The '98-'99 Y-pipe won't work on a 2000-2002 because it doesn't have a flange on the passenger side pipe. It has to be welded in place. It took them till the 2000 model year to figure out it might be better to have both sides flanged and secured with bolts. (xtrooper)

- To Cure Y pipe banging mufflex has come up with this solution. 1, 2. You can purchase this from Thunder Racing.

Flowtech: When engeneering the Flowtech headers the premise was to build a Hooker set using half the budget; it shows. The welds, and flanges are very thin and the primaries have a dent in them to “clear” the k-member. Even with the “clearance dent” people are still having issues. Because of the low quality TPS has stopped carrying the Flowtech line of LT”s. If you need a budget header look into the new Pacesetter design or spend the dough on hooker/jet hots.

Others available but not reviewed:

-Thunder Racing Headers

-Dynatech

-Stainless Works

-PPC

-SuperMaxx

-TTS

How to install: Flat out, install will vary from car to car and from the type of header you choose, some are easier to install then others.

- Great Pacesetter install guide done by foff667

- SLP guide (done by bomax if i recall)

- Mac Mid's Guide

- Awesome writeup by DirtyJohn! QTP LT's + TSP duals: Install and review.

A few install tips:

- Patience; if after working for several hours without any apparent results take a break. Things often have a way of working out coming back from a fresh start.

- A breaker bar is your friend.

- All LT's go in from the bottom.

- The stock cat bolts will often break, especially on the older 98-99 cars, don’t worry about it.

- Use plenty of penetrating oil on all the cat to manifold bolts.

- Have a buddy/wife/gf help you out when need be.

- Remove the oil diverter for a bit more room on the drivers side install.

- May or may not have to knotch the K-member and floor board clearance (CamaroCain).

- Steering shaft removal may or may not be required. (For my install I couldn’t get the damn thing to budge, so I used a die grinder to grind down the block tab to get the drivers side header to slide up). Heed the warning on the steering shaft before removal.

- Have all the proper tools before the outset of installation; jack/jack stands and/or ramps, basic hand tools (3/8, 1/2 drive ratchet, 10mm, 12mm, 15mm, ect sockets), hammer. Optional but very handy tools that may or may not be needed; sawz-all, die grinder, 2x4 4x4 pieces of wood and/or some bricks.

- Get the car as high as safely possible. It's alot higher then you think. (During my own install I had the rear on ramps and the front was propped up with my jack on a 4x4 piece of wood to get the extra clearance need.)

- Don’t think it has to be mentioned but I’ll say it anyway; use safety goggles where applicable and make sure your car is secured on the ramp/jack stands before getting under the car and working on it. Basically don’t do any stupid ****

- Give yourself plenty of time to get the install done; first time around factor in 5-12hrs. Don’t worry if it takes you longer, just concentrate on getting it done right and gaining the experience

- Typical prices a shop will charge for an install are 300-500 dollars depending on location. If you have the time, you owe it to yourself to give the install a shot yourself. It’s not that hard and doesn’t require alot of technical knowledge or experience. If you run into trouble during the install come to the boards in a calm and collected manner and you'll get your answer in no time.

- Will you need tuning after headers: Every car varies, you wont know until the headers are installed and you've put some miles on the car. Headers usually cause the car to run a bit rich but its nothing stock tune cant handle. If you want full advantage of the new headers then you'll want a tune. Just plan accordingly; if you know your not going to install big mods (h/c) sometime in the near future then I’d go ahead and get a tune. If you plan for a new cam and/or heads then hold off on tuning for the headers and get a tune once the h/c is installed, it'll save you the time and money of having to tune twice. If you don’t want to pay for a full tune you can always pick up a used MAFT (mass air fuel translator) and dial in your A/F ratio a bit.

- Where to buy:

1) Pacesetters: TSP (http://www.texas-speed.com) has the best deals on pacesetters. And they are the only place to get the TSP Rumbler catback and dual setup

2) Kooks: Contact Matt from TTP (http://www.ttperformance.net/) you'll usually get the best deal from him.

3) Jet hot/hookers: Go to the sponsor forums, every so often there is a GP (group purchase) on jet hots and you can get a great price.

4) QTP: Contact Barry from QTP (http://www.quicktimeperformance.com/) and see what kind of price he can get you.

C. Y-Pipes

What they are: Jet hot catted/ory SLP stock replacement Y Mufflex Random Tech stock replacement catted Y Pacesetter ORY

- Catted Y denotes a Y with cats; ORY denotes a Y with no cats

What they do: Connect the headers to the catback and aid in exhaust flow provided it matches the rest of your system. Meaning keep the diameter relatively consistent, 3" is the most popular, a 2.5" is fine as well and will give you a bit more clearance if your lowered.

What to look for: Y pipes come in all different shapes and diameters, if you can, get the Y made by the same company that you got your headers from. Meaning if you get the Hooker LT's then get the hooker Y, ect. All Y pipes are not directly swappable. If you wish to use another manufactures Y for your setup you are most likely going to have to modify it to fit.

-Those looking to get Pacesetters; there Y is a toss up, some people's are "acceptable", others are straight ****. Pace didn’t put to much time or development into making a quality Y and it shows in the collector. Your best bet is to go with a custom Y or modify your Pace ORY like Larry did.

Those with Hooker/Jethot/Pacesetters can now rejoice, TSP has just come out with a 3” Catted Y pipe to fit your headers. They use high flow carsound cats. At 350 a pop you can rest assure that this is the Y-pipe you want to get. They also offer an ORY as well.

- A custom Y is great since its taylored to your exact setup and will allow you to get the best fitment and clearance. Just pick up a Flowmaster merge collector and cats if you need and have a shop fab up the rest; depending on shop it should run you 100-200 bucks not including parts (i.e. merge collector)

- Do Not invest in a new Y pipe unless you plan to stick with shorties/stock manifolds, and even at that it’s barely worth it since you'll gain practically nothing by a new Y on stock manifolds. If you buy a new Y for stock manifolds/shorties you'll need to replace the Y you just bought if you add LT's or mids in the future.

- If you need cats for emissions purposes then do not purchase an ORY and then try and weld cats in them, just spring for the catted Y or purchase some cats, flowmaster merge collector and have a shop fab the rest. Alot of ORY's don’t have enough room to accommodate cats. If you still want to try it then get the smallest cats you can; slp's or random tech.

- The '98-'99 Y-pipe won't work on a 2000-2002 because it doesn't have a flange on the passenger side pipe. It has to be welded in place. It took them till the 2000 model year to figure out it might be better to have both sides flanged and secured with bolts. (xtrooper)

- To Cure Y pipe banging mufflex has come up with this solution. 1, 2. You can purchase this from Thunder Racing.

Last edited by TheBlurLS1; 11-07-2006 at 05:02 PM.

#3

D. Duals

What they are:

1) X-pipe setups 1 (South FL) 2 3 (DVST8OR) 4 (Y2KSS).

2) H-Pipe setup: 1 (Lanes)

What they do: See Y pipe

What to look for: Your only actual viable option is an X pipe or H pipe. Which is better will always be debated. Most people go with an X pipe, in a nutshell an X-pipe will net you more power and torque and an H-pipe will have a slightly better sound. Both are great, so choose what you like, either is better then a traditional Y setup. Where duals shine is power under the curve.

- When it comes to duals you have 2 options; dumped before the axel or going all the way out the back. The former is a more popular option because of cost. A complete dual setup dumped should run you 500 bucks or less. If you desire to go out the back it'll cost you, you'll need some custom over the axel work or you can go a cheaper route and go under the axel. Both have there advantages; dumped are very cost effective and have a great hp/$ ratio. However since the exhaust is now exiting under the car; cab noise is more prevalent, you'll notice rattles you never knew you had, and you'll feel the resonance. Duals out the back are more expensive but you'll get the hp and sound of the duals without the little annoyances of the dumped setup. (My advice would be to go with dumps first and see how you like it and whats acceptable to you, if you find the annoyances unbearable you can always complete the duals out the back, just pick up where the dumps left off and go over the axel or under.

- TSP has pretty much hit a home run with its new exhaust line, in addition to the Rumbler catback, Catted and ORY, they have introduced a direct fit bolt on True Duals. The system is a direct bolt on to the Hooker/Jethot/Pacesetter LT’s, others will work but you will need adjusting and fitting. The mufflers used are 18” Dynomax Bullets which offer a slightly more subdued sound over a 12” bullet. The setup runs around ~$430.

More pics of the TSP Duals:

- 1

- 2

- 3

- 4

- 5

- If you plan for dumps you can go 3" piping all through out. If you are lowered or plan to lower or want duals all the way back go with 2.5", you'll have more ground clearance and more room to allow for going over the axel depending on how you set it up. You can also go 3" up to the X pipe and then reduce to 2.5".

- Both 2.5" and 3" will support plenty of power, most likely more then you'll ever produce. Choose your piping based on fitment and clearance, not power.

- When you run duals you'll want an X/H pipe for the scavaging and equalizing effect, you wont get that from straight pipes off of the collector.

- True Duals w/ Side Pipes 1 2 (Rene - Trans Am WS6 RGS)

How to install: You have a few options:

- Have a shop fab up the whole setup for you

- Buy just an X/H pipe from jegs or summit and mufflers and have a shop fab the rest

- Buy a Dr. Gas kit and have a shop fab the rest

E. Cut-outs

What they are: Flowtech QTP electric cutout

What they do:

What to look for: An electric cutout is the best bet, you can be loud when you need/want it to be and quite when you need/want it to be all at the flip of a switch. A standard cut you you’ll need to get under the car to cap or uncap it. A cutout is a great mod for cheap horsepower and sound.

How/Where to install: For an electric cutout follow the wiring guide instructions. For both type of cutouts you'll need to have them welded in. You have a few options of placement. The easiest is the I-pipe as there is plenty of room. You can also run dual cutouts in place of where the cats would be (on a LT' setup). Dual cats and cutouts can be done but the fitment will be very close and you'll need to run some small cats.

F. Misc/Emissions

- Gaskets: Stick with the metal gaskets, either new or re-used. Don’t bother with the paper gaskets that often come with your headers, you'll just increase the chance of leaks.

-Header Bolts: Oem bolts are fine, again new or re-used. If you want to spend the money you can get some stage 8 locking bolts, they are not necessary though. Header bolts are only required to be torqued down to 18ft-lb's, which is not alot. Do Not over torque the bolts as you run the risk of stripping the threads on the heads. They are aluminum after all. Torque the bolts from the center out.

- Clamps: Invest in some good band clamps; they can be had from a variety of sponsors or found at your local parts store. U-bolt clamps are pieces of ****. Another option you have is to flange your system.

-If you’re using clamps and are still having exhaust leaks try buying some aluminum tape that can be found at Lowes or home depot. Wrap the tape around the collector; whether header or Y pipe, for thicker area for the clamp to seal up too.

- Cats: Magnaflow/Carsound cats are the best overall option; they flow great and can be had for a great price, especially on ebay.

1) You’ll want pt# 94106 for a 2.5" inlet/outlet and 94109 for a 3" inlet/out.

- o2 Extension and Sims: When buying Long tubes you'll need to get 2 o2 extensions to connect the front o2 sensors as the o2 bungs have now been moved so far down the sensor wont reach the connection. Most Y/X/H pipes do not have rear o2 provisions so you'll need to run 2 o2 Sims to prevent an SES light. You can also turn off the codes with edit/hp tuner/predator and bypass the need for the Sims.

1) DO NOT PUT O2 SIMS ON THE FRONT O2 SENSORS (B1S1) (B2S1). The pcm determines the A/F ratio from the front o2 sensors when it goes into closed loop.

I. Emission

1) When buying headers you have the option to buy them with or without emissions provisions. Find out your states/counties emissions standards before buying.

2) If you know your emissions requirements you can buy whichever setup meets your needs.

3) If your state only has OBDII testing you may remove your Air and/or EGR setup (only 98-00 cars have EGR). You can purchase the racing headers and get rid of the above systems. As long as you arent throwing any codes you will pass the OBDII test.

4) If your car has a sniffer/visual test you'll need to decide how you want to play it; either comply with the rules and keep your Air/Egr and purchase the headers with the emissions provisions or try and find a shop that will over look those missing systems.

5) 9 times out of 10 you will not pass the sniffer test without cats.

6) Go here (bomax) to remove your Air/Egr. 00-02 cars go here

7) If you want to swap 98-99 and 00-02 headers around you'll need to remove your Air system or purchases the Air tubes from the year the headers were made for since the 98-99 and 00-02 have different Air tube setup.

8) It should go without saying but if you want to swap 01-02 headers on your 98-00 you'll need to remove you EGR system.

9) 00 are an oddball year as the EGR and Air setups are different then the 98-99.

10) When removing the Air system on the 00+ cars you'll be left with a vacuum hose that you'll need to plug up.

11) Removing your Air/EGR/rear o2's will set off an SES light but will not effect performance at all.

12) If you plan to keep your Air system with your LT's you'll want to run Air Restrictor plates (bomax)

What they are:

1) X-pipe setups 1 (South FL) 2 3 (DVST8OR) 4 (Y2KSS).

2) H-Pipe setup: 1 (Lanes)

What they do: See Y pipe

What to look for: Your only actual viable option is an X pipe or H pipe. Which is better will always be debated. Most people go with an X pipe, in a nutshell an X-pipe will net you more power and torque and an H-pipe will have a slightly better sound. Both are great, so choose what you like, either is better then a traditional Y setup. Where duals shine is power under the curve.

- When it comes to duals you have 2 options; dumped before the axel or going all the way out the back. The former is a more popular option because of cost. A complete dual setup dumped should run you 500 bucks or less. If you desire to go out the back it'll cost you, you'll need some custom over the axel work or you can go a cheaper route and go under the axel. Both have there advantages; dumped are very cost effective and have a great hp/$ ratio. However since the exhaust is now exiting under the car; cab noise is more prevalent, you'll notice rattles you never knew you had, and you'll feel the resonance. Duals out the back are more expensive but you'll get the hp and sound of the duals without the little annoyances of the dumped setup. (My advice would be to go with dumps first and see how you like it and whats acceptable to you, if you find the annoyances unbearable you can always complete the duals out the back, just pick up where the dumps left off and go over the axel or under.

- TSP has pretty much hit a home run with its new exhaust line, in addition to the Rumbler catback, Catted and ORY, they have introduced a direct fit bolt on True Duals. The system is a direct bolt on to the Hooker/Jethot/Pacesetter LT’s, others will work but you will need adjusting and fitting. The mufflers used are 18” Dynomax Bullets which offer a slightly more subdued sound over a 12” bullet. The setup runs around ~$430.

More pics of the TSP Duals:

- 1

- 2

- 3

- 4

- 5

- If you plan for dumps you can go 3" piping all through out. If you are lowered or plan to lower or want duals all the way back go with 2.5", you'll have more ground clearance and more room to allow for going over the axel depending on how you set it up. You can also go 3" up to the X pipe and then reduce to 2.5".

- Both 2.5" and 3" will support plenty of power, most likely more then you'll ever produce. Choose your piping based on fitment and clearance, not power.

- When you run duals you'll want an X/H pipe for the scavaging and equalizing effect, you wont get that from straight pipes off of the collector.

- True Duals w/ Side Pipes 1 2 (Rene - Trans Am WS6 RGS)

How to install: You have a few options:

- Have a shop fab up the whole setup for you

- Buy just an X/H pipe from jegs or summit and mufflers and have a shop fab the rest

- Buy a Dr. Gas kit and have a shop fab the rest

E. Cut-outs

What they are: Flowtech QTP electric cutout

What they do:

What to look for: An electric cutout is the best bet, you can be loud when you need/want it to be and quite when you need/want it to be all at the flip of a switch. A standard cut you you’ll need to get under the car to cap or uncap it. A cutout is a great mod for cheap horsepower and sound.

How/Where to install: For an electric cutout follow the wiring guide instructions. For both type of cutouts you'll need to have them welded in. You have a few options of placement. The easiest is the I-pipe as there is plenty of room. You can also run dual cutouts in place of where the cats would be (on a LT' setup). Dual cats and cutouts can be done but the fitment will be very close and you'll need to run some small cats.

F. Misc/Emissions

- Gaskets: Stick with the metal gaskets, either new or re-used. Don’t bother with the paper gaskets that often come with your headers, you'll just increase the chance of leaks.

-Header Bolts: Oem bolts are fine, again new or re-used. If you want to spend the money you can get some stage 8 locking bolts, they are not necessary though. Header bolts are only required to be torqued down to 18ft-lb's, which is not alot. Do Not over torque the bolts as you run the risk of stripping the threads on the heads. They are aluminum after all. Torque the bolts from the center out.

- Clamps: Invest in some good band clamps; they can be had from a variety of sponsors or found at your local parts store. U-bolt clamps are pieces of ****. Another option you have is to flange your system.

-If you’re using clamps and are still having exhaust leaks try buying some aluminum tape that can be found at Lowes or home depot. Wrap the tape around the collector; whether header or Y pipe, for thicker area for the clamp to seal up too.

- Cats: Magnaflow/Carsound cats are the best overall option; they flow great and can be had for a great price, especially on ebay.

1) You’ll want pt# 94106 for a 2.5" inlet/outlet and 94109 for a 3" inlet/out.

- o2 Extension and Sims: When buying Long tubes you'll need to get 2 o2 extensions to connect the front o2 sensors as the o2 bungs have now been moved so far down the sensor wont reach the connection. Most Y/X/H pipes do not have rear o2 provisions so you'll need to run 2 o2 Sims to prevent an SES light. You can also turn off the codes with edit/hp tuner/predator and bypass the need for the Sims.

1) DO NOT PUT O2 SIMS ON THE FRONT O2 SENSORS (B1S1) (B2S1). The pcm determines the A/F ratio from the front o2 sensors when it goes into closed loop.

I. Emission

1) When buying headers you have the option to buy them with or without emissions provisions. Find out your states/counties emissions standards before buying.

2) If you know your emissions requirements you can buy whichever setup meets your needs.

3) If your state only has OBDII testing you may remove your Air and/or EGR setup (only 98-00 cars have EGR). You can purchase the racing headers and get rid of the above systems. As long as you arent throwing any codes you will pass the OBDII test.

4) If your car has a sniffer/visual test you'll need to decide how you want to play it; either comply with the rules and keep your Air/Egr and purchase the headers with the emissions provisions or try and find a shop that will over look those missing systems.

5) 9 times out of 10 you will not pass the sniffer test without cats.

6) Go here (bomax) to remove your Air/Egr. 00-02 cars go here

7) If you want to swap 98-99 and 00-02 headers around you'll need to remove your Air system or purchases the Air tubes from the year the headers were made for since the 98-99 and 00-02 have different Air tube setup.

8) It should go without saying but if you want to swap 01-02 headers on your 98-00 you'll need to remove you EGR system.

9) 00 are an oddball year as the EGR and Air setups are different then the 98-99.

10) When removing the Air system on the 00+ cars you'll be left with a vacuum hose that you'll need to plug up.

11) Removing your Air/EGR/rear o2's will set off an SES light but will not effect performance at all.

12) If you plan to keep your Air system with your LT's you'll want to run Air Restrictor plates (bomax)

Last edited by jrp; 07-04-2005 at 12:14 AM.

#4

I. Intake

A. Lids:

What they are:

What they do: increase airflow and thus horse power

What to look for: a lid is a lid is a lid. They will all net you the same horsepower. Pick your lid based on looks and price.

- 00+ cars will need to use an air breather which is required for lids that do not that the provision on the lid. Air breathers can be had from a variety of sponsors.

How to install: http://www.installuniversity.com/ins...id_install.htm

B. Filters:

What they are:

What they do: larger surface area increases airflow and thus more power.

What to look for: k&n/powershot filters have shown little gains on the ls1; there retaining quality is the ability to clean them and re-use them

How to install: if you can’t figure it out sell your car

C. Bellows:

What they are: slp fernco bakerhose airflow system

What they do: straighten out the airflow

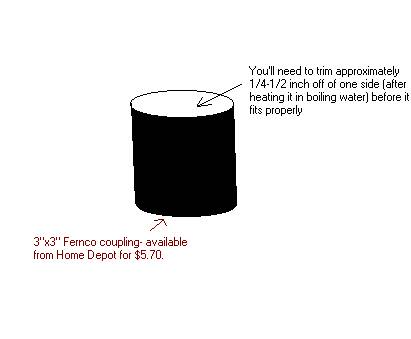

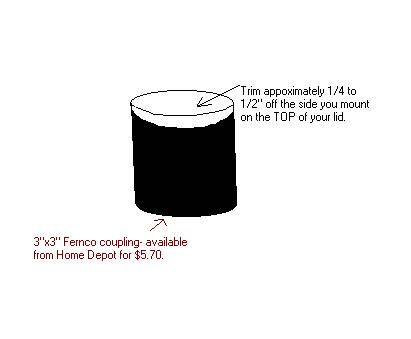

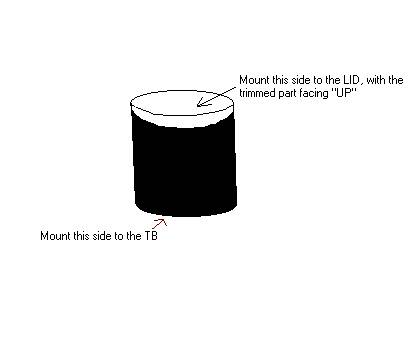

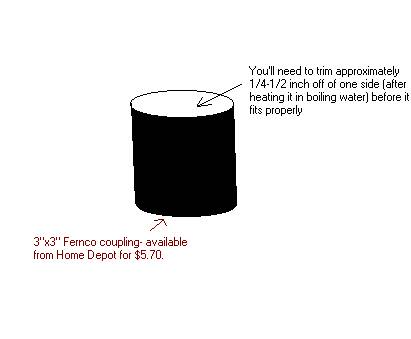

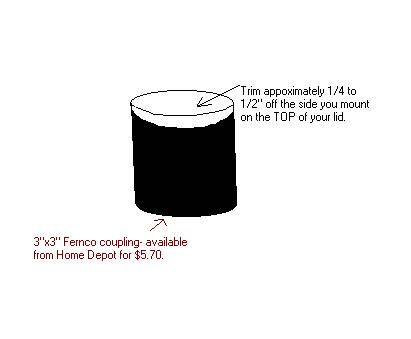

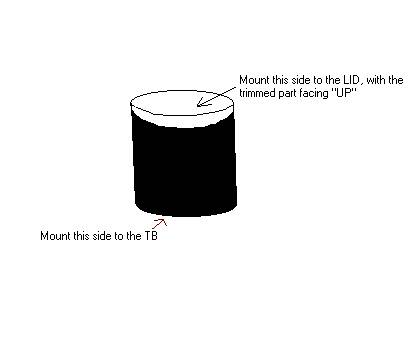

What to look for: an appearance mod. Chalk it up to the every little bit helps category in terms of "performance". Fernco can be bought at your local home depot or Lowes. The size you want is 3"x3", it is in the plumbing department.

How to install: see filter installation

- Tips: if buying a ferco, bakerhose, airflow systems bellow cutting and fitting may be required. Heat up the tubing in the microwave to soften up the material for easier cutting and fitting. It will also prevent the stiff bellow from cracking or loosening up your lid.

- Pretty good deal here...

Less than $6 for a smooth bellows.

Step one: Go to home depot and buy a 3"x3" Fernco rubber coupling.. It should be around $5-6.

Then Proceed to remove all clamps and labeling, and put it in boiling water for about 10 minutes to soften the rubber. After softening, trim approximately 1/4" to 1/2" off of ONE side of the coupling to make a better fit.

After you've trimmed it and are satisfied with it, put it back in the hot water for 5-10 minutes. Otherwise you'll have trouble getting one end over the throttle body.

I did this, because I originally had my nitrous nozzle in the bellows, and now i'm spraying in the airbox.

Hope this helps someone, because it took me almost an hour to put it all together (the info) The job only takes about 15 minutes.

Matt (Ole1830)

D. Maf:

What they are:

What they do: "...Aftermarket mafs, don't make power, due to larger size, they make power, by tricking the computer into seeing less air, therefore the computer gives more timing, and less fuel..." (Ryan 'slow')

What to look for: PORT/SWAP/DE-SCREEN AT YOUR OWN RISK. The stock maf is good for 500hp. If by chance your maxing out your MAF contact your tuner and see what he/she recommends.

How to install: http://www.installuniversity.com/ins.../mafh_swap.htm

E. TB:

What they are:

What they do: increase airflow

What to look for: look into Bo White, Cammin BeaSST, shaner (s2/s3), and bauer. They all make great ported throttle bodies.

- The '98-'99 F-body throttle bodies have a smaller cam compared to the '00-'02 F-body TB's

- The smaller radius throttle cam opens the throttle plate faster

How to install: http://www.installuniversity.com/ins...ar/tb_swap.htm

F. Intake Manifold:

What they are: SLP Ls6 w/ egr provision Holley LSX

What to look for: the ls6 intake will serve a great majority of setups. All 01-02 cars already have an ls6 intake. If you have a 98-00 and want to do an ls6 swap you'll need the new ls6 coolant tubes and plugs. If you have a stroker or are the kind of person who wants all the horsepower they can get look into the LSX.

- the 78mm LSX has shown marginal improvements over the ls6 intake and quite frankly not worth the swap. Stay with the ls6 intake or upgrade to the 90/90 setup

- Intake Manifold Test. Flow tests all the the popular intakes and some carb style as well.

- LSX dyno results.

- The Ls6 intake has many different part numbers buts its the same intake

- The only way to tell 100% if you are buying an ls6 intake, especially used is to ask for pics of the bottom. The vette LS1 intake does not have an EGR provision so its easy to pass that off as an LS6 if you are none the wiser. The difference between the LS1 and LS6 intakes can be see here; the ls1 intake is on the left and the ls6 is on the right.

How to install: http://www.ls1howto.com/index.php?article=5

G. CAI

What they are: FTRA SSRA: (1)(2)(3) BGRA

What they do: take in cold air from the bottom/front of the car

What to look for: fast toys ram air (FTRA) and super sucker ram air (SSRA) are to very popular choices. BGRA is an option for you ws6 hood guys. Either option you choice you'll want the air box sealed.

How to install: follow the provided instructions that come with the setup.

H. FIPK:

What they are:

What they do: same effect as the lid.

What to look for: a ws6 hood or slp z hood with functionality is bests suited for maximum airflow.

How to install: see CAI install.

A. Lids:

What they are:

What they do: increase airflow and thus horse power

What to look for: a lid is a lid is a lid. They will all net you the same horsepower. Pick your lid based on looks and price.

- 00+ cars will need to use an air breather which is required for lids that do not that the provision on the lid. Air breathers can be had from a variety of sponsors.

How to install: http://www.installuniversity.com/ins...id_install.htm

B. Filters:

What they are:

What they do: larger surface area increases airflow and thus more power.

What to look for: k&n/powershot filters have shown little gains on the ls1; there retaining quality is the ability to clean them and re-use them

How to install: if you can’t figure it out sell your car

C. Bellows:

What they are: slp fernco bakerhose airflow system

What they do: straighten out the airflow

What to look for: an appearance mod. Chalk it up to the every little bit helps category in terms of "performance". Fernco can be bought at your local home depot or Lowes. The size you want is 3"x3", it is in the plumbing department.

How to install: see filter installation

- Tips: if buying a ferco, bakerhose, airflow systems bellow cutting and fitting may be required. Heat up the tubing in the microwave to soften up the material for easier cutting and fitting. It will also prevent the stiff bellow from cracking or loosening up your lid.

- Pretty good deal here...

Less than $6 for a smooth bellows.

Step one: Go to home depot and buy a 3"x3" Fernco rubber coupling.. It should be around $5-6.

Then Proceed to remove all clamps and labeling, and put it in boiling water for about 10 minutes to soften the rubber. After softening, trim approximately 1/4" to 1/2" off of ONE side of the coupling to make a better fit.

After you've trimmed it and are satisfied with it, put it back in the hot water for 5-10 minutes. Otherwise you'll have trouble getting one end over the throttle body.

I did this, because I originally had my nitrous nozzle in the bellows, and now i'm spraying in the airbox.

Hope this helps someone, because it took me almost an hour to put it all together (the info) The job only takes about 15 minutes.

Matt (Ole1830)

D. Maf:

What they are:

What they do: "...Aftermarket mafs, don't make power, due to larger size, they make power, by tricking the computer into seeing less air, therefore the computer gives more timing, and less fuel..." (Ryan 'slow')

What to look for: PORT/SWAP/DE-SCREEN AT YOUR OWN RISK. The stock maf is good for 500hp. If by chance your maxing out your MAF contact your tuner and see what he/she recommends.

How to install: http://www.installuniversity.com/ins.../mafh_swap.htm

E. TB:

What they are:

What they do: increase airflow

What to look for: look into Bo White, Cammin BeaSST, shaner (s2/s3), and bauer. They all make great ported throttle bodies.

- The '98-'99 F-body throttle bodies have a smaller cam compared to the '00-'02 F-body TB's

- The smaller radius throttle cam opens the throttle plate faster

How to install: http://www.installuniversity.com/ins...ar/tb_swap.htm

F. Intake Manifold:

What they are: SLP Ls6 w/ egr provision Holley LSX

What to look for: the ls6 intake will serve a great majority of setups. All 01-02 cars already have an ls6 intake. If you have a 98-00 and want to do an ls6 swap you'll need the new ls6 coolant tubes and plugs. If you have a stroker or are the kind of person who wants all the horsepower they can get look into the LSX.

- the 78mm LSX has shown marginal improvements over the ls6 intake and quite frankly not worth the swap. Stay with the ls6 intake or upgrade to the 90/90 setup

- Intake Manifold Test. Flow tests all the the popular intakes and some carb style as well.

- LSX dyno results.

- The Ls6 intake has many different part numbers buts its the same intake

- The only way to tell 100% if you are buying an ls6 intake, especially used is to ask for pics of the bottom. The vette LS1 intake does not have an EGR provision so its easy to pass that off as an LS6 if you are none the wiser. The difference between the LS1 and LS6 intakes can be see here; the ls1 intake is on the left and the ls6 is on the right.

How to install: http://www.ls1howto.com/index.php?article=5

G. CAI

What they are: FTRA SSRA: (1)(2)(3) BGRA

What they do: take in cold air from the bottom/front of the car

What to look for: fast toys ram air (FTRA) and super sucker ram air (SSRA) are to very popular choices. BGRA is an option for you ws6 hood guys. Either option you choice you'll want the air box sealed.

How to install: follow the provided instructions that come with the setup.

H. FIPK:

What they are:

What they do: same effect as the lid.

What to look for: a ws6 hood or slp z hood with functionality is bests suited for maximum airflow.

How to install: see CAI install.

Last edited by jrp; 12-10-2005 at 10:39 PM.

#5

10 Second Club

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

More Header install tips: (sorry if I repeat something already said...I didn't read every word)

I have installed 3 sets of headers on these cars so far (PPCs, FLPs & Pacesetters) and I thoiught I'd share some useful tips that we used.

ALL - Remove the steering linkage. It works for all headers. Avoid the nice gouges on the driver's side header, and hours of cursing. Turn the steering wheel first so you can get at both bolts. The bottom one can be challenging....a 12" ext & a wobbly works. Lock the stering wheel & remove the 2 bolts, and yank it off. Removing the bottom bolt completely is required. This will let the driver's side header slip right in!

PPCs - The y-pipe is the B on these. Get a BIG rubber mallet, a LARGE set of channel locks, and a can of WD-40. Wiggle, pound spray, & cuss. It will go. The I-pipe will probably be too long & need to be cut.

PaceSetters - cut a 2' long piece off the k-member's lip. You'll neeed to hold the header in place to see where the cut is needed. A sawzall, a dremel with a cut-off wheel & a pair of vice grips works very nicely. Cut 2 lines straight in, etch along the k-member with the cut-off wheel, & then bend it back & forth with vice grips or whatever you can grab it with. It should braak right off. Use a grinding wheel on a dremel to touch up the rough edge.

FLPs - The worst part about these is the collector & y-pipe clamps. Take the bolts out & spread them apart, put both pipes in & then squeeze them together again with channel locks so you can get the nut started. The I-pipe will probably be too long & need to be cut on these too.

AIR Tubes - on the PPCs the stock one work fine. On 01-01 FLPs, go get a passenger side tube off a 2000, and use the existing passenger side for the driver's side. The flange on the header is clocked ~ 90* from the stock poistion. Hold the one you're going to use up to the flange & draw a line on the tube where one of bolt holes is. Do the same for both sides. Then go get the ends cut off, rotated & welded back on. Usually rotating one way or the other will result in a better angle. I think we rotated the pass side CCW & the drivers side CW.

EGR Tubes - these are NOT fun to put on. The flange is down by the starter & you cannot reach it with the tube in place. A magnetic socket to hold the bolt & some grease on the gasket to hold it in place worked for me. Along with 4 extensions & 2 wobblies. Took me an hour and every word I knew.

ALL - have a Predator handy. It is not unusual to throw a code when you first start the car.

Hope this helps.

Mark

I have installed 3 sets of headers on these cars so far (PPCs, FLPs & Pacesetters) and I thoiught I'd share some useful tips that we used.

ALL - Remove the steering linkage. It works for all headers. Avoid the nice gouges on the driver's side header, and hours of cursing. Turn the steering wheel first so you can get at both bolts. The bottom one can be challenging....a 12" ext & a wobbly works. Lock the stering wheel & remove the 2 bolts, and yank it off. Removing the bottom bolt completely is required. This will let the driver's side header slip right in!

PPCs - The y-pipe is the B on these. Get a BIG rubber mallet, a LARGE set of channel locks, and a can of WD-40. Wiggle, pound spray, & cuss. It will go. The I-pipe will probably be too long & need to be cut.

PaceSetters - cut a 2' long piece off the k-member's lip. You'll neeed to hold the header in place to see where the cut is needed. A sawzall, a dremel with a cut-off wheel & a pair of vice grips works very nicely. Cut 2 lines straight in, etch along the k-member with the cut-off wheel, & then bend it back & forth with vice grips or whatever you can grab it with. It should braak right off. Use a grinding wheel on a dremel to touch up the rough edge.

FLPs - The worst part about these is the collector & y-pipe clamps. Take the bolts out & spread them apart, put both pipes in & then squeeze them together again with channel locks so you can get the nut started. The I-pipe will probably be too long & need to be cut on these too.

AIR Tubes - on the PPCs the stock one work fine. On 01-01 FLPs, go get a passenger side tube off a 2000, and use the existing passenger side for the driver's side. The flange on the header is clocked ~ 90* from the stock poistion. Hold the one you're going to use up to the flange & draw a line on the tube where one of bolt holes is. Do the same for both sides. Then go get the ends cut off, rotated & welded back on. Usually rotating one way or the other will result in a better angle. I think we rotated the pass side CCW & the drivers side CW.

EGR Tubes - these are NOT fun to put on. The flange is down by the starter & you cannot reach it with the tube in place. A magnetic socket to hold the bolt & some grease on the gasket to hold it in place worked for me. Along with 4 extensions & 2 wobblies. Took me an hour and every word I knew.

ALL - have a Predator handy. It is not unusual to throw a code when you first start the car.

Hope this helps.

Mark

#6

Header Basics by Loren Barnes, President, S&S Headers, Inc.

You have probably heard words like: back pressure, scavenging, tuned length, merged collector, rotational firing order, compatible combination and many others that meant something, but how they relate to a header may be a little vague. This article should give you a basic understanding of how a header works, what the terminology means, and how it plays a part in the header's performance gains.

The first misconception that needs to be cleared up is that a header relieves backpressure, but a certain amount of backpressure is needed for optimum performance. Just the opposite is true. A good header not only relieves the backpressure, but goes one step further and creates a vacuum in the system. When the next cylinder's exhaust valve opens, the vacuum in the system pulls the exhaust out of the cylinder. This is what the term "Scavenging" means.

The first consideration is the proper tube diameter. Many people think "Bigger is Better", but this is not the case. The smallest diameter that will flow enough air to handle the engine's c.c. at your desired Red Line R.P.M. should be used. This small diameter will generate the velocity (air speed) needed to "Scavenge" at low R.P.M.s. If too small a diameter is used the engine will pull hard at low R.P.M.s but at some point in the higher R.P.M.s the tube will not be able to flow as much air as the engine is pumping out, and the engine will "sign off" early, not reaching its potential peak R.P.M. This situation would require going one size larger in tube diameter.

The second consideration is the proper tube length. The length directly controls the power band in the R.P.M. range. Longer tube lengths pull the torque down to a lower R.P.M. range. Shorter tubes move the power band up into a higher R.P.M. range. Engines that Red Line at 10,000 R.P.M. would need short tube lengths about 26" long. Engines that are torquers and Red Line at 5,500 R.P.M.s would need a tube length of 36". This is what is meant by the term "Tuned Length". The tube length is tuned to make the engine operate at a desired R.P.M. range.

The third consideration is the collector outlet diameter and extension length. This is where major differences occur between four cylinder engines and V-8 engines. The optimum situation is the four cylinder because of it's firing cycle. Every 180 degree of crankshaft rotation there is one exhaust pulse entering the collector. This is ideal timing because, as one pulse exits the collector, the next exhaust valve is opening and the vacuum created in the system pulls the exhaust from the cylinder. In this ideal 180 degree cycling the collector outlet diameter only needs to be 20% larger than the primary tube diameter. (Example: 1 3/4" primary tubes need a 2" collector outlet diameter.) The rule of thumb here is two tube sizes. This keeps the velocity fast to increase scavenging, especially at lower R.P.M.s. Going to a larger outlet diameter will hurt the midrange and low R.P.M. torque.

The amount of straight in the collector extension can move the engines torque up or down in the R.P.M. range. Longer extension length will pull the torque down into the midrange.

Engines that "Red Line" at 10,000 R.P.M. would only need 2" of straight between the collector and the megaphone. This is just enough length to straighten out the air flow before it enters the megaphone. This creates an orifice action that enhances exhaust velocity.

In the case of V-8 firing order, the five pulses fire alternately back and forth from left to right collector, giving the ideal 180 degree firing cycle. Then it fires two in succession into the left collector, then two in succession into the right collector. If the proper collector outlet diameter is being used (two sizes larger than primaries) the two pulses in succession load up the collector with more air than it can flow. This results in a very strong midrange torque, but causes the engine to "sign off" early, not reaching its potential peek R.P.M. The improper firing order on a V-8 engine results in the need to use large diameter collectors so the engine will perform well at high R.P.M.s. Unfortunately the large diameter collectors cause a tremendous drop in air velocity, resulting in less scavenging through the entire R.P.M. range.

Often cams are used with extended valve timing to help the exhaust cycling. This results in valve timing overlap (Intake and Exhaust valves both open at T.D.C.) which causes a "Reversion"cycle in the exhaust. When this happens, exhaust actually backs up into the cylinder causing intake air to be pushed back out the intake. This reversion causes "Standoff" (fuel blowing out of the Intake) at low R.P.M.s. This whole improper cycling has resulted in a number of "Cure Alls" to help stop this reversion and standoff.

The plentum intake was created to stop the fuel "Standoff". Then came "Anti Reversionary" Cones in the exhaust tubes, and stepped tube diameter in the header, extended collector lengths and even plentums in the exhaust tubes.

In this chain of events beginning with improper firing order, a series of cures has developed, each one causing a new problem.

The optimum cure to this whole problem is to correct the exhaust firing cycle. The two cylinders that fire in succession into each collector have to be separated. This can be done partially by a "Tri-Y" header, where the four primary tubes from each bank merge into two secondary tubes (separating the two pulses firing in succession) and finally collect into a single collector. This type of header helps, but the two pulses are still coming back together at the collector.

The second optimum cure is to cross the two center tubes from each bank, across the engine running them into the collector on the opposite side. This makes the firing cycle in each collector 180 degrees apart, the same as a four cylinder engine. Once this firing order is achieved, the small collector outlet diameter can be used and the "High Velocity Scavenging" at low R.P.M.s cures the reversion problems and eliminates the need for extreme cam duration.

This sounds so easy, you are probably asking why wasn't this done from the start?

If you have ever seen a set of 180 degree headers you would understand.

On today's cars, with space virtually nonexistent, crossing four tubes either under the oil pan or around the front or rear of the engine presents major problems. On racing applications where it is possible, there is still the problem of keeping the tube length down to a reasonable 32" long. If that's not enough challenge, then try to arrange the tubes into each collector so they fire in a "Rotational Firing" pattern. Then you have, what has been called "A Bundle of Snakes".

Arranging the tubes to fire rotationally adds to the scavenging capabilities. The exhaust gas exiting one tube, passing across the opening of the tube directly beside it, creates more suction on that tube than it would on a tube on the opposite side of the collector.

The next problem is "Turbulence" in the collector. When four round tubes are grouped together in a square pattern, so a collector can be attached, you notice a gapping hole in the center of the four tubes. The standard method in manufacturing headers is to cap this hole off with a square plate. This plate in the center of the four tubes creates dead air space, or turbulence, disrupting the high velocity in the collector. This problem is solved by using a "Merge Collector". This collector is formed from four tubes, cut at approximately an 8 degree angle on two sides. When the tubes are all fitted together they form a collector with a "Pyramid" in the center. This has eliminated the need for the square plate and has taken up some of the volume inside the collector, speeding up the air velocity.

Other methods of curing this problem are: fabricating a pyramid out of sheet metal and welding it over the hole between the tubes, or squaring the tubes on two sides so they fit together forming a "+" weld in the center eliminating the hole all together.

You can see that there are a great many factors that go into making a good header. When the header, intake system, and cam timing are all designed to operate to their maximum in the same R.P.M. range, then you have a "Compatible Combination". This combination can be tuned to deliver maximum power at any desired R.P.M. range.

These are some of the "Basics" you need to know about building a good high performance header. There are many other adjustments that can be made to fine tune a header, but this should give you a basic understanding of how all the components work together.

You have probably heard words like: back pressure, scavenging, tuned length, merged collector, rotational firing order, compatible combination and many others that meant something, but how they relate to a header may be a little vague. This article should give you a basic understanding of how a header works, what the terminology means, and how it plays a part in the header's performance gains.

The first misconception that needs to be cleared up is that a header relieves backpressure, but a certain amount of backpressure is needed for optimum performance. Just the opposite is true. A good header not only relieves the backpressure, but goes one step further and creates a vacuum in the system. When the next cylinder's exhaust valve opens, the vacuum in the system pulls the exhaust out of the cylinder. This is what the term "Scavenging" means.

The first consideration is the proper tube diameter. Many people think "Bigger is Better", but this is not the case. The smallest diameter that will flow enough air to handle the engine's c.c. at your desired Red Line R.P.M. should be used. This small diameter will generate the velocity (air speed) needed to "Scavenge" at low R.P.M.s. If too small a diameter is used the engine will pull hard at low R.P.M.s but at some point in the higher R.P.M.s the tube will not be able to flow as much air as the engine is pumping out, and the engine will "sign off" early, not reaching its potential peak R.P.M. This situation would require going one size larger in tube diameter.

The second consideration is the proper tube length. The length directly controls the power band in the R.P.M. range. Longer tube lengths pull the torque down to a lower R.P.M. range. Shorter tubes move the power band up into a higher R.P.M. range. Engines that Red Line at 10,000 R.P.M. would need short tube lengths about 26" long. Engines that are torquers and Red Line at 5,500 R.P.M.s would need a tube length of 36". This is what is meant by the term "Tuned Length". The tube length is tuned to make the engine operate at a desired R.P.M. range.

The third consideration is the collector outlet diameter and extension length. This is where major differences occur between four cylinder engines and V-8 engines. The optimum situation is the four cylinder because of it's firing cycle. Every 180 degree of crankshaft rotation there is one exhaust pulse entering the collector. This is ideal timing because, as one pulse exits the collector, the next exhaust valve is opening and the vacuum created in the system pulls the exhaust from the cylinder. In this ideal 180 degree cycling the collector outlet diameter only needs to be 20% larger than the primary tube diameter. (Example: 1 3/4" primary tubes need a 2" collector outlet diameter.) The rule of thumb here is two tube sizes. This keeps the velocity fast to increase scavenging, especially at lower R.P.M.s. Going to a larger outlet diameter will hurt the midrange and low R.P.M. torque.

The amount of straight in the collector extension can move the engines torque up or down in the R.P.M. range. Longer extension length will pull the torque down into the midrange.

Engines that "Red Line" at 10,000 R.P.M. would only need 2" of straight between the collector and the megaphone. This is just enough length to straighten out the air flow before it enters the megaphone. This creates an orifice action that enhances exhaust velocity.

In the case of V-8 firing order, the five pulses fire alternately back and forth from left to right collector, giving the ideal 180 degree firing cycle. Then it fires two in succession into the left collector, then two in succession into the right collector. If the proper collector outlet diameter is being used (two sizes larger than primaries) the two pulses in succession load up the collector with more air than it can flow. This results in a very strong midrange torque, but causes the engine to "sign off" early, not reaching its potential peek R.P.M. The improper firing order on a V-8 engine results in the need to use large diameter collectors so the engine will perform well at high R.P.M.s. Unfortunately the large diameter collectors cause a tremendous drop in air velocity, resulting in less scavenging through the entire R.P.M. range.

Often cams are used with extended valve timing to help the exhaust cycling. This results in valve timing overlap (Intake and Exhaust valves both open at T.D.C.) which causes a "Reversion"cycle in the exhaust. When this happens, exhaust actually backs up into the cylinder causing intake air to be pushed back out the intake. This reversion causes "Standoff" (fuel blowing out of the Intake) at low R.P.M.s. This whole improper cycling has resulted in a number of "Cure Alls" to help stop this reversion and standoff.

The plentum intake was created to stop the fuel "Standoff". Then came "Anti Reversionary" Cones in the exhaust tubes, and stepped tube diameter in the header, extended collector lengths and even plentums in the exhaust tubes.

In this chain of events beginning with improper firing order, a series of cures has developed, each one causing a new problem.

The optimum cure to this whole problem is to correct the exhaust firing cycle. The two cylinders that fire in succession into each collector have to be separated. This can be done partially by a "Tri-Y" header, where the four primary tubes from each bank merge into two secondary tubes (separating the two pulses firing in succession) and finally collect into a single collector. This type of header helps, but the two pulses are still coming back together at the collector.

The second optimum cure is to cross the two center tubes from each bank, across the engine running them into the collector on the opposite side. This makes the firing cycle in each collector 180 degrees apart, the same as a four cylinder engine. Once this firing order is achieved, the small collector outlet diameter can be used and the "High Velocity Scavenging" at low R.P.M.s cures the reversion problems and eliminates the need for extreme cam duration.

This sounds so easy, you are probably asking why wasn't this done from the start?

If you have ever seen a set of 180 degree headers you would understand.

On today's cars, with space virtually nonexistent, crossing four tubes either under the oil pan or around the front or rear of the engine presents major problems. On racing applications where it is possible, there is still the problem of keeping the tube length down to a reasonable 32" long. If that's not enough challenge, then try to arrange the tubes into each collector so they fire in a "Rotational Firing" pattern. Then you have, what has been called "A Bundle of Snakes".

Arranging the tubes to fire rotationally adds to the scavenging capabilities. The exhaust gas exiting one tube, passing across the opening of the tube directly beside it, creates more suction on that tube than it would on a tube on the opposite side of the collector.

The next problem is "Turbulence" in the collector. When four round tubes are grouped together in a square pattern, so a collector can be attached, you notice a gapping hole in the center of the four tubes. The standard method in manufacturing headers is to cap this hole off with a square plate. This plate in the center of the four tubes creates dead air space, or turbulence, disrupting the high velocity in the collector. This problem is solved by using a "Merge Collector". This collector is formed from four tubes, cut at approximately an 8 degree angle on two sides. When the tubes are all fitted together they form a collector with a "Pyramid" in the center. This has eliminated the need for the square plate and has taken up some of the volume inside the collector, speeding up the air velocity.

Other methods of curing this problem are: fabricating a pyramid out of sheet metal and welding it over the hole between the tubes, or squaring the tubes on two sides so they fit together forming a "+" weld in the center eliminating the hole all together.

You can see that there are a great many factors that go into making a good header. When the header, intake system, and cam timing are all designed to operate to their maximum in the same R.P.M. range, then you have a "Compatible Combination". This combination can be tuned to deliver maximum power at any desired R.P.M. range.

These are some of the "Basics" you need to know about building a good high performance header. There are many other adjustments that can be made to fine tune a header, but this should give you a basic understanding of how all the components work together.

Last edited by jrp; 05-28-2005 at 06:20 PM.

#7

These three circles illustrate the difference in internal square-inch area between 2.25-, 2.50-, and 3-inch exhaust pipes. We’ve calculated the area based on a wall thickness of 0.065. The 2.25-inch pipe has a flow area of 3.80 square inches, a 2.5-inch system increases the area 25 percent to 4.7 square inches, and a 3-inch pipe pumps the area up to 6.8 square inches.

Last edited by jrp; 05-28-2005 at 06:20 PM.

Trending Topics

#8

My Flowtech headers came today. Here are a couple quick pics. These were the uncoated. Along with them, I recieved the gaskets (header and collector), new header bolts with lock washers, O2 extensions, EGR block off, EGR and AIR gaskets, small stickers (for my tool box), and a set of generic directions.

Pic 1

Pic 2

Pic 3

Pic 1

Pic 2

Pic 3

Last edited by jrp; 09-08-2004 at 06:53 AM.

#9

Alrighty...2 more pics.

These are of the "dent" in the primary and the inside of the collector. The dent looks about as professional as a dent can look. What I mean is that it does not look like it's been wacked with a 3lb sledge.

Dent in Primary

Inside Collector