Lets build a mid-engine Trans Am - need advice

#261

TECH Apprentice

iTrader: (3)

Join Date: May 2004

Location: Ambridge PA

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

I thought the MCSS engine had the front wheel drive bellhousing bolt pattern? You could bolt on a G6 trans I believe. Sell the LS1 and T56 and buy the parts you need. I wanted to do a mid-engine in my Monza but the term budget and mid engine in a car smaller than yours does not go hand in hand.

#262

TECH Apprentice

iTrader: (3)

Join Date: May 2004

Location: Ambridge PA

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

I also looked into the th325-4L. It was a front drive longitutally mounted trans. I read it could be built to handle 450 hp. Not too sure about it. Also the th425 is the same way mounts the engine north and south. It is chain driven and I think you could modify it to run an all wheel drive transfer case off the pulleys for the chain. It's only a 3 speed but it could be made to go AWD.

#264

I also looked into the th325-4L. It was a front drive longitutally mounted trans. I read it could be built to handle 450 hp. Not too sure about it. Also the th425 is the same way mounts the engine north and south. It is chain driven and I think you could modify it to run an all wheel drive transfer case off the pulleys for the chain. It's only a 3 speed but it could be made to go AWD.

Here are some pics.

Last edited by JasonWW; 12-30-2008 at 09:29 AM.

#265

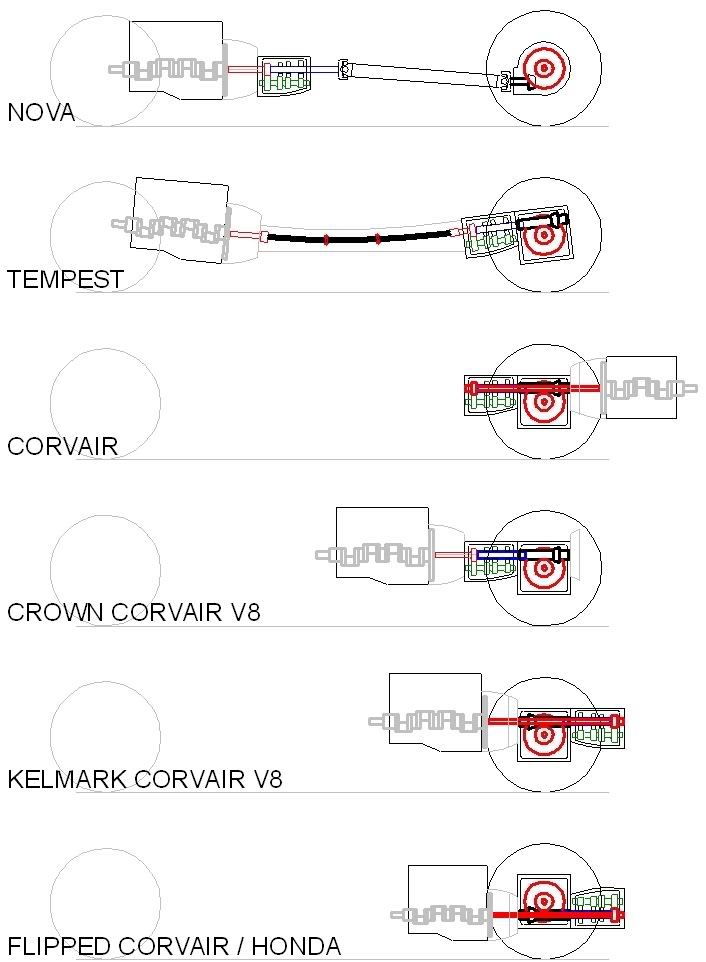

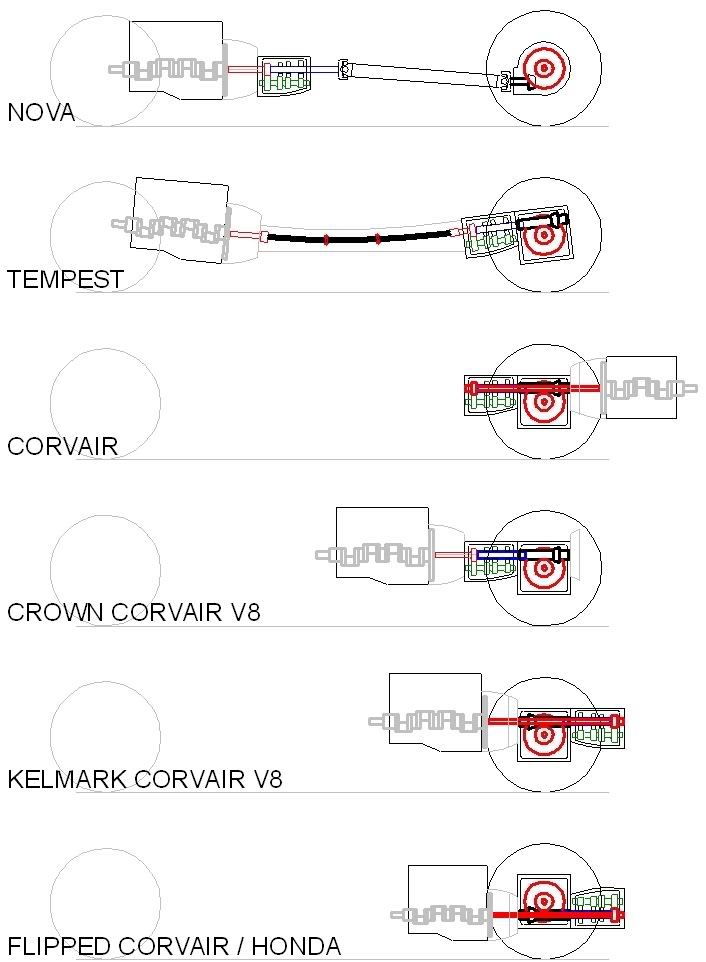

For those curious about how the mid-engine transaxle works, check out these pics. They all have pretty much the same design. A long input shaft to get past a mid mounted diff and the output shaft is either above or below the input. This output shaft has a pinion gear on the front of it and drives the ring gear and diff.

Last edited by JasonWW; 12-30-2008 at 09:43 AM.

#266

Some more neat info concerns the Corvairs which were rear engined.

Take a look at the 1961 Tempest layout attached below. Look familiar? It's the same basic thing the C5 and C6 vette uses today! I thought it was something new. I also found out the Porsche 928 (1977+) also uses a rear mounted trans.

Take a look at the 1961 Tempest layout attached below. Look familiar? It's the same basic thing the C5 and C6 vette uses today! I thought it was something new. I also found out the Porsche 928 (1977+) also uses a rear mounted trans.

For the 1961 Pontiac Tempest, the Saginaw 4-speed (or 3-speed) gearbox was moved to the rear by splitting the input gear, extending it with the world's most expensive driveshaft (8660 steel, carefully heat treated and every one Magnafluxed). It was 3/4" diameter and flexed in a long curve (almost 4" dip) going through a couple of guide bearings. The only other change was the shorter output shaft with splines that engaged internal splines in the hollow pinion shaft in the attached differential housing. A swing axle rear suspension completed the deal. This whole layout was the brainchild of some guy named John DeLorean.

The Corvair used the same gearbox and the Tempest differential housing but the input gear had to come from the rear. So both the pinion shaft and the gearbox output shaft (blue) are hollow... and the (24" long) input gear shaft (red) runs through them. Note that the gearbox is still facing the same direction as in th Nova and the Tempest... AND all the components inside are still turning the direction they designed for. Note also that the Corvair crankshaft is actually turning the same direction as the Nova and Tempest in the car (i.e. clockwise when viewed from the front of the car) but is considered a reverse rotation engine when viewed by convention.

The Corvair used the same gearbox and the Tempest differential housing but the input gear had to come from the rear. So both the pinion shaft and the gearbox output shaft (blue) are hollow... and the (24" long) input gear shaft (red) runs through them. Note that the gearbox is still facing the same direction as in th Nova and the Tempest... AND all the components inside are still turning the direction they designed for. Note also that the Corvair crankshaft is actually turning the same direction as the Nova and Tempest in the car (i.e. clockwise when viewed from the front of the car) but is considered a reverse rotation engine when viewed by convention.

Last edited by JasonWW; 12-30-2008 at 10:00 AM.

#267

TECH Apprentice

iTrader: (3)

Join Date: May 2004

Location: Ambridge PA

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

The 425 can be built to take a lot of punishment like a turbo 400. Yes it does turn opposite so some parts are specific to the 425. The chain drive is very strong (I don't know where you heard it was weak). The engine is not offset? The 425 does run next to the engine put it makes up for it with a short output shaft on the drivers side and a longer one with a support on the passenger side. The axles are the same length.With a cheap BOPC to Chevy Adapter and a bracket for the pas side output shaft support your LS1 can bolt up. They even make torque convertors for the LS1 to 400/425 swap. It is no heavier than your t56. The only drawback that I see is it is only a three speed. The 325-4L is a weaker trans but can be built to handle some power and it gives you 4 speeds. I know there are many ways to skin the cat and this is just an option.

#268

Maybe it was the diff that was weak? I can't remember. It also HAS to weigh more than a T56. Didn't they offset the engines to the passenger side a little so as to make the half shafts closer to the same legnth?

The main reason I ruled it out is the same as the Syclone, SS Trailblazer and Cadillac setups. The driveshaft has to go under the crank. That means the engine has to be mounted a lot higher than normal. You can see the extra height needed in this pic. Once you move the engine back for the TH-425 it may be sticking up above the fender line. That's high, don't you think?

This is with the engine as far forward as it will go for better weight distribution. It's really not much different than using a transfer case and mounting the dif housing right next to the oil pan. I'm not much of a fan of automatics, either. Especially these older units that tend to upshift and downshift when you least expect it.

The main reason I ruled it out is the same as the Syclone, SS Trailblazer and Cadillac setups. The driveshaft has to go under the crank. That means the engine has to be mounted a lot higher than normal. You can see the extra height needed in this pic. Once you move the engine back for the TH-425 it may be sticking up above the fender line. That's high, don't you think?

This is with the engine as far forward as it will go for better weight distribution. It's really not much different than using a transfer case and mounting the dif housing right next to the oil pan. I'm not much of a fan of automatics, either. Especially these older units that tend to upshift and downshift when you least expect it.

Last edited by JasonWW; 12-30-2008 at 12:18 PM.

#269

Here's a better picture of the "Theoretical" TH425 setup.

If that chain setup is really that strong, then that's what I would need in a transfer case. Something that can take big torque.

Here it is with the engine mounted backwards. Now there is room to drop the engine lower and put the diff further away. The weight distribution is better as well.

I could even move the rear wheels back a little for more space and to help with the driveline angles.

If that chain setup is really that strong, then that's what I would need in a transfer case. Something that can take big torque.

Here it is with the engine mounted backwards. Now there is room to drop the engine lower and put the diff further away. The weight distribution is better as well.

I could even move the rear wheels back a little for more space and to help with the driveline angles.

Last edited by JasonWW; 12-30-2008 at 01:24 PM.

#270

Here's what I mean about the engine offset. This guy is using SBC with the 325-4L in a Fiero. He made sure that the left and right side axles were the same legnth. See how the engine is shifted to the passenger side?

Check this out. This guy is saying the same thing I did above about turning the engine around.

More pics:

Check this out. This guy is saying the same thing I did above about turning the engine around.

After I had already started my conversion, I found out that it can be done differently to better distribute the weight. By rotating the entire engine/trans 180 deg so that the pulleys are at the back of the car, you can get a lot more of the weight in front of the rear axle. The differential housing then needs to be rotated 180 deg to an upside-down position to make the axles turn the opposite direction. This also places the pinion shaft below the axle centerline, effectively lowering the engine. I have never done a swap this way, so I can only speculate what changes must be made. First off, the tie rods can probably stay where they are. Also, the trunk may be able to be retained, or at least more of it. I would expect that the oil pan modification would be more extensive. If I were to do another longitudinal swap, I would definitely do a reverse rotation due to the weight distribution advantages.

Last edited by JasonWW; 12-30-2008 at 01:05 PM.

#271

Here's something else cool I learned about the TH425.

Monza, do you have any more info on these trans?

Hmmm, maybe a TH-200R4 based unit?

The '66 & '67 Toro's also had the switch-pitch torque convertor in the 425 trans. The switch-pitch would be a slick set up for you; with the flip of a switch you can go from about 1400 stall speed to more like 2400. Maybe you already know all this stuff but you can convert a NON switch-pitch 425 to a switch-pitch.

325-4L

Used 1982-85 in Buick Riviera, Olds Toronado and Cadillac Eldorado.

This was an hydraulically controlled front wheel drive overdrive transmission with an electronically controlled lock-up torque converter .

Gear Ratios:

2.74:1 1st gear

1.57:1 2nd gear

1.00:1 3rd gear

0.70:1 4th gear

2.07:1 reverse

Used 1982-85 in Buick Riviera, Olds Toronado and Cadillac Eldorado.

This was an hydraulically controlled front wheel drive overdrive transmission with an electronically controlled lock-up torque converter .

Gear Ratios:

2.74:1 1st gear

1.57:1 2nd gear

1.00:1 3rd gear

0.70:1 4th gear

2.07:1 reverse

Last edited by JasonWW; 12-30-2008 at 01:39 PM.

#272

The TH425

Chain widths:

325-4L 1.25"

325 1.75"

425 2"

Anyone have any weight info? I can't find anything.

Called the TH425 in FWD form, the transmission's torque converterTorque converter was separated from its planetary gearset with the torque converter driving the gearset through a 2" wide silent chain-drive called Hy-Vo, riding on two 12" sprockets. The Hy-Vo chain drive was developed by GM's Hydra-Matic Division and Morse Chain Division of Borg-Warner. The chains were made from a very strong hardened steel and required no tensioners or idler pulleys because they were pre-stretched on a special machine at the factory. Although the rotation direction of the transmission's gearing had to be reversed, a large number of components were shared with the conventional TH400.

325-4L 1.25"

325 1.75"

425 2"

Anyone have any weight info? I can't find anything.

Last edited by JasonWW; 12-30-2008 at 02:29 PM.

#273

TECH Apprentice

iTrader: (3)

Join Date: May 2004

Location: Ambridge PA

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

I like your idea of flipping it around and moving the weight forward. How about this, just a thought and not sure it would work. Take the pulleys and chain off, put a gear set on that would run the trans in the correct direction and load it with th-400 parts. That would run the axles in the right direction.

#274

I like your idea of flipping it around and moving the weight forward. How about this, just a thought and not sure it would work. Take the pulleys and chain off, put a gear set on that would run the trans in the correct direction and load it with th-400 parts. That would run the axles in the right direction.

#275

I don't think there is a gearset that large yet is light weight enough. How far apart would the centerlines be, 20"? That would require a pair of 10" diameter gears. I don't think anybody makes a V-drive that big. Maybe there is a unit used in an industrial machine that can be fitted, but I have no idea where to look for such a machine.

I found some more info on the chains used. What's interesting is that the big bad 425 only uses a 2" wide chain. That's really surprising to me. What's even better is that the BW 4472 transfer case I talked about before uses the same basic chain as the TH325 which is 1 3/4" wide. So maybe a gutted 4472 would be a lot stronger than I thought. Now I'm really interested.

I found some more info on the chains used. What's interesting is that the big bad 425 only uses a 2" wide chain. That's really surprising to me. What's even better is that the BW 4472 transfer case I talked about before uses the same basic chain as the TH325 which is 1 3/4" wide. So maybe a gutted 4472 would be a lot stronger than I thought. Now I'm really interested.

Last edited by JasonWW; 12-31-2008 at 02:29 AM.

#277

Like so:

If I use an offset rear diff I may be able to use a single, one piece driveshaft. Like so.

Here is a 4472 Syclone transfer case adapted to the T56.

I'm not saying the 2 pieces have to be attached like this, but it can be done. I'm assuming the chain would be the weakest link in this drivetrain, so if the chain or case breaks, I can just replace it with a stronger unit. The cost is low and it does seem possible. I may just go this route.

Last edited by JasonWW; 01-05-2009 at 10:39 AM.

#278

I think I've found my transfer case. The Dana/Spicer 20 (D20). It's a stronger and quieter updated version of the old WWII era D18. It's a gear drive design with a small, compact cast iron case. It is only 8.5" tall and 17" wide. Length is not important. It weighs 80lbs which is not bad considering most chain drives weigh more.

They are easy and cheap to find ($50 local) and rebuild. Parts are still around as well. Once I remove the extra gears that are for low range, the weight should drop even more. The D300 would be even better as it's stronger still, but their harder to find.

The strongest case I know of is the NP205 which we've mentioned before. Compared to the D20, it is 3.5" taller and 60lbs heavier. Yes, they weigh 140lbs! I can get one local for $150, but I don't think I need that much strength compared to the weight. If I break the D20, then I may go to the NP205.

Now I need to locate a strong axle from a 4x4 with IFS and a pumpkin on the passenger side. Once I spin it around and flip it over it should be in the back passenger side of my car and turning the proper direction and using the proper drive side of the gears.

Should I try and extend one side of the 8.8 IRS diff? I really don't know.

They are easy and cheap to find ($50 local) and rebuild. Parts are still around as well. Once I remove the extra gears that are for low range, the weight should drop even more. The D300 would be even better as it's stronger still, but their harder to find.

The strongest case I know of is the NP205 which we've mentioned before. Compared to the D20, it is 3.5" taller and 60lbs heavier. Yes, they weigh 140lbs! I can get one local for $150, but I don't think I need that much strength compared to the weight. If I break the D20, then I may go to the NP205.

Now I need to locate a strong axle from a 4x4 with IFS and a pumpkin on the passenger side. Once I spin it around and flip it over it should be in the back passenger side of my car and turning the proper direction and using the proper drive side of the gears.

Should I try and extend one side of the 8.8 IRS diff? I really don't know.

Last edited by JasonWW; 01-05-2009 at 01:08 AM.

#279

Size comparison next to a typical, modern, aluminum, chain drive unit.

Inside the D20:

The stronger NP205 is 12" tall and 18" wide. It's a lot heavier, too. You can tell it's bigger just from the picture below.

Inside the D20:

The stronger NP205 is 12" tall and 18" wide. It's a lot heavier, too. You can tell it's bigger just from the picture below.

Last edited by JasonWW; 01-05-2009 at 10:43 AM.

#280

TECH Enthusiast

iTrader: (27)

Join Date: Aug 2005

Location: Anheuser Busch, Houston Texas

Posts: 741

Likes: 0

Received 0 Likes

on

0 Posts

205s are tanks, and expensive too. That's the most sought after xfer case for wheeling. If you can get one for 150, I'd say do it. Hell I might buy it off you if you do and don't use it. The upside is rebuild kits are pretty accessible. Bear in mind though 205s came in a lot of flavors; divorced, mated, Dodge, Chevy. They all have different spline and input shaft designs, unfortunately. I guess that's cool if you are gutting them.

I know you mentioned this before, but 203 aluminum chain drive might be more economical and definitely lighter. The downside is the chain, of course.

Don't you need a front axle with a driver's side input? I don't think you can run those upside down, but you can turn them around and run them backwards. Just thinking about my D44 on my Dodge, I don't think it was designed to be flipped top to bottom.

I know you mentioned this before, but 203 aluminum chain drive might be more economical and definitely lighter. The downside is the chain, of course.

Don't you need a front axle with a driver's side input? I don't think you can run those upside down, but you can turn them around and run them backwards. Just thinking about my D44 on my Dodge, I don't think it was designed to be flipped top to bottom.