never seen this

#1

On The Tree

Thread Starter

iTrader: (2)

Join Date: Jul 2006

Posts: 104

Likes: 0

Received 0 Likes

on

0 Posts

Started shortblocking my new 383 setup, which is my old setup, with le3 heads and le4 cam plus alot of other new things. While getting ready to put my crank in, I noticed an etching on the block surface were the main caps bolt up. Is electrolysis possible here? I would think not, but I guess it could happen with a bad ground. Could it be that my crank was trying to move? I know for sure the caps were tight when i dissasembled it. I need you guys to help me out here b/c I am pretty stumped on this. BTW 2-bolt block, eagle 3.75 crank, eagle h-beams,and je pistons. Please feel free to reply.

#3

We have seen that a lot on the 2 bolt blocks when you get into some higher HP applications and if your up dating to better heads and mor hp power this issue may get worse. As the caps are walking do to narrow 2 bolt registers which can not stableize the caps from moving side to side. And using more stroke will magnify the problem. If your engine is over 400 horse it can been done using a 2 bolt block but the question is for how long!!!!!!

Here is a good link to look over.

http://www.chevelles.com/forums/showthread.php?t=38173

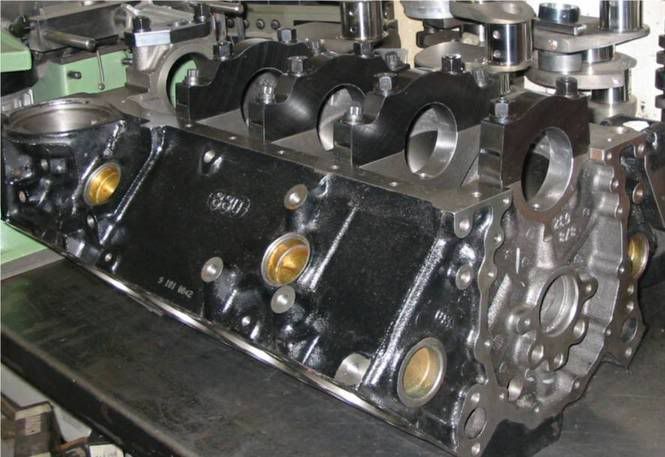

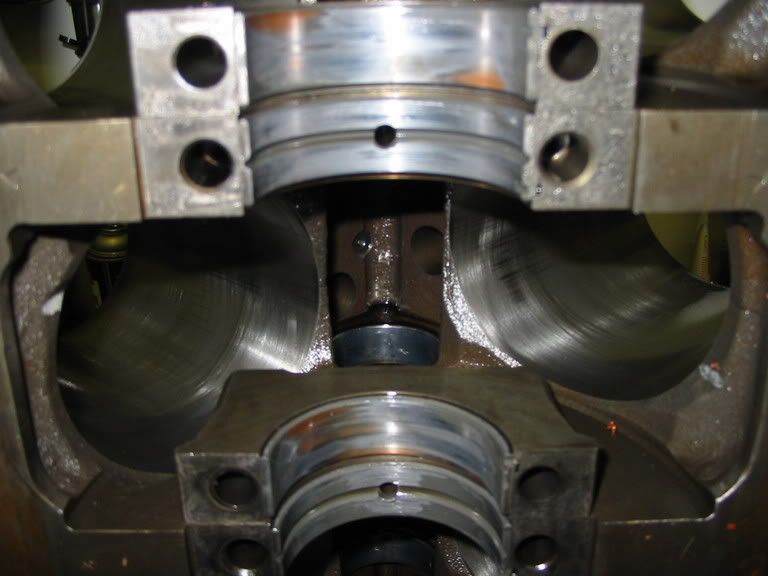

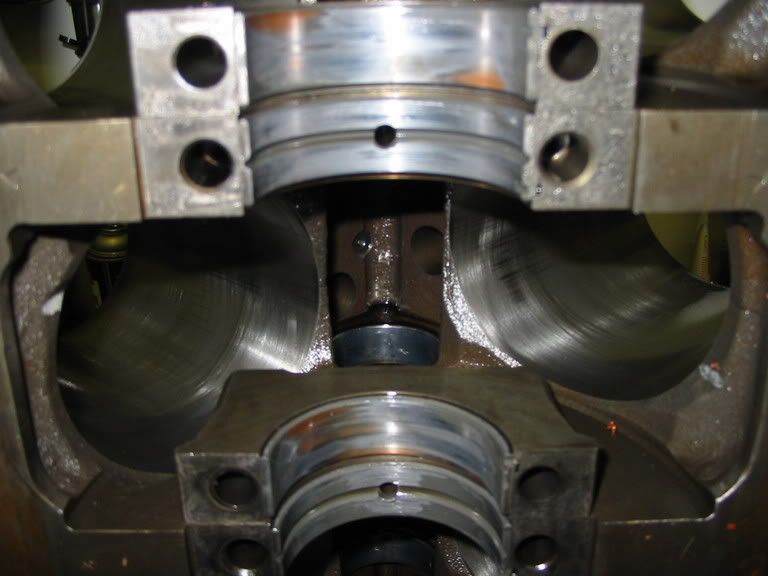

Here is pic of a block that came to our shop from NY and this engine was in a 420 horse circle track car and after 12 races was loosing oil pressure and when it was torn down this is what they found. The only thing it really hurt was the mains on the crank and they only had to go .010 under on the crank and after we put 3 center splayed caps on and after 2 years of running and 2 rebuilds they say every things looks fine. The owner took the advise from some one that said a 2 bolt block was good for 500 horse and all he said is lesson learned.

And they said they had a stud kit as well as studs don't make the caps stronger as its still a cast cap and its like putting new rod bolts in an old set of rods it does not make the rods any strong its just a better rod bolt.

Ther is really no quick fix for this problem but it has to be addressed if your going to make more HP.

Here is a good link to look over.

http://www.chevelles.com/forums/showthread.php?t=38173

Here is pic of a block that came to our shop from NY and this engine was in a 420 horse circle track car and after 12 races was loosing oil pressure and when it was torn down this is what they found. The only thing it really hurt was the mains on the crank and they only had to go .010 under on the crank and after we put 3 center splayed caps on and after 2 years of running and 2 rebuilds they say every things looks fine. The owner took the advise from some one that said a 2 bolt block was good for 500 horse and all he said is lesson learned.

And they said they had a stud kit as well as studs don't make the caps stronger as its still a cast cap and its like putting new rod bolts in an old set of rods it does not make the rods any strong its just a better rod bolt.

Ther is really no quick fix for this problem but it has to be addressed if your going to make more HP.

Last edited by CNC BLOCKS N/E; 08-11-2013 at 07:53 AM.

#5

On The Tree

Thread Starter

iTrader: (2)

Join Date: Jul 2006

Posts: 104

Likes: 0

Received 0 Likes

on

0 Posts

thanks for all of your great input guys. i have personally never seen or heard of this. i think you definately nailed the situation, but now i have to solve this problem.

I guess i need a LT-4 block. got one ?

I guess i need a LT-4 block. got one ?

#6

TECH Fanatic

iTrader: (2)

Join Date: Nov 2006

Location: Aztec, NM

Posts: 1,360

Likes: 0

Received 0 Likes

on

0 Posts

You could also use a stud girdle to tie the caps together and help keep them from moving under stress. It just depends on how much HP you are wanting to make, as to if this would be able to support your needs.

#7

From what I heard the girdle is only a small band aid as the caps will still walk as this is only here say but sounds right. Aggod four bolt block mey be a good start or a 2 bolt with splayed center caps if the cylinder walls test fine.

Good luck with your build.

Good luck with your build.

Trending Topics

#9

Originally Posted by WYD-01

do you think this will work CNC

machine surface area on block were main caps bolt

then, place splayed caps on the block and line hone?

machine surface area on block were main caps bolt

then, place splayed caps on the block and line hone?

Here is pic of a block we machined for another shop as this guy wanted a front billet cap and a strap on the rear main cap. Good luck with your build.