LSx into Jet Boat??

#1

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Hey all,

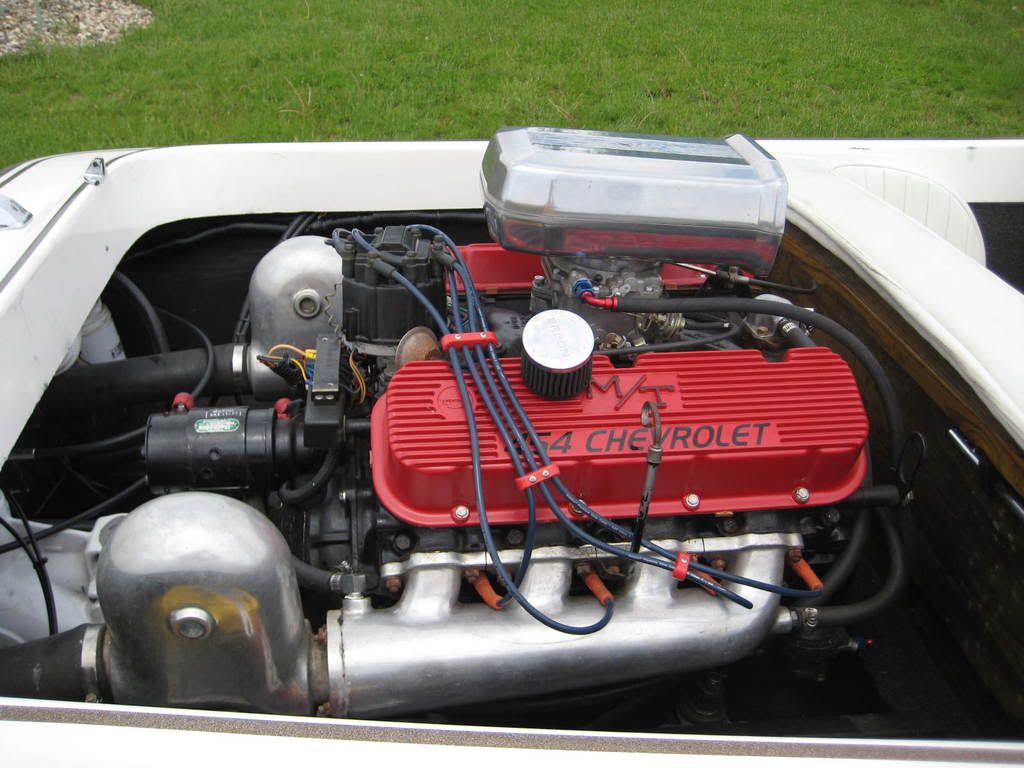

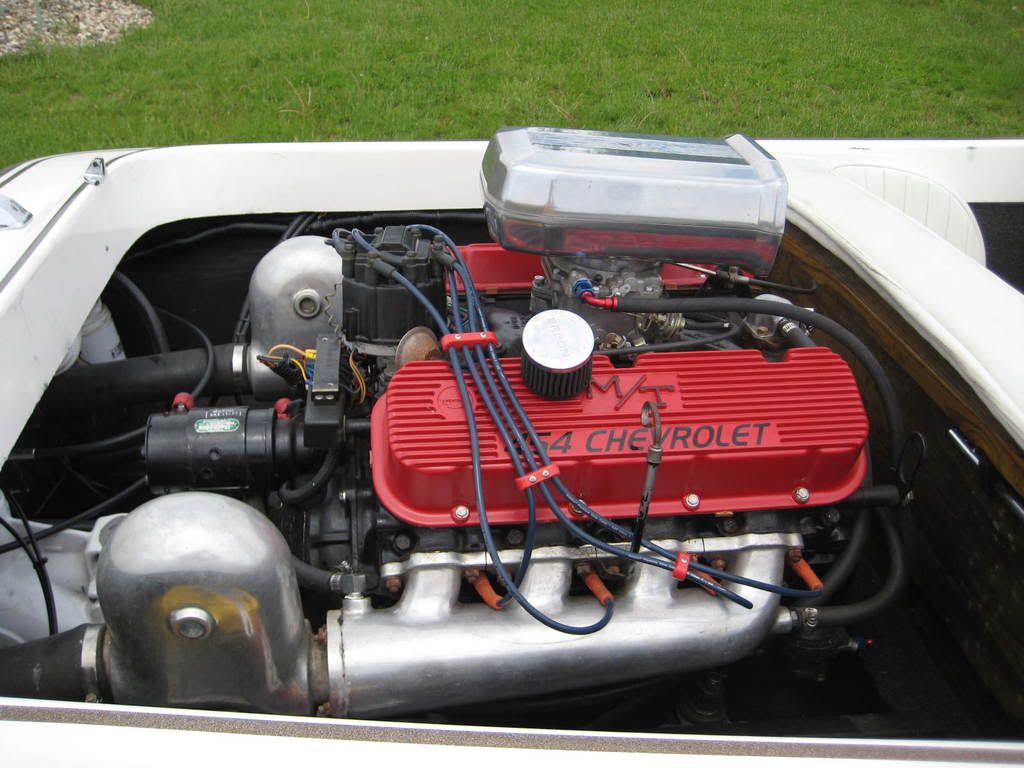

I picked up this boat a couple months ago. It's a 1975 Avenger Jet Boat with a 454 chevy and a Berkley pump.

This P.O.S. 454 is not doing it for me, and I've had nothing but problems with it. Runs like crap (imo), and I can only get ~47 mph out of it.

So.....being no stranger to LSx swapping, I am REALLY contemplating stuffing a 6.0L LQ9 in it.

Now I am just thinking out loud here, so bear with me, and feel free to chime in...

Here's each system broken down:

Jet Pump: The bellhousing from the BBC should work on the LS block, right? Could I re-use the big block flywheel, or is it different? I would need a stainless impeller that would withstand the increased HP and RPM of the LS.

Cooling: I'd need to find a waterpump block-off since the engine is cooled by water from the jet-pump.

Exhaust: Two options here...could either pick up the Indmar water jacketed manifolds/risers, or flip over some longtube headers and go over the transom with them. How the hell do I run a wideband O2 with water injected exhaust??

Engine mounting: Not an issue. I will fabricate some mounts.

Engine accessories: My bellhousing has the starter mounted on top of it, which is kind of weird. May re-use that if possible, or maybe use the automotive starter. Will not have a water pump, AC compressor, or power-steering pump. How can I just run the alternator off the crank? Lots of idler pulleys?

Wiring/Tuning: Probably just have Speartech build me a custom harness for this application. How will the engine react to not having a trans attached? (no VSS, etc) I have EFI Live, so I'm pretty much set for tuning it myself.

Fuel System: More than likely will just get a Walbro inline like I did for my '69. Works great! I will have to run a return though, since the boat currently does not have one.

I welcome any comments and/or advice! Am I missing anything?

Thanks,

J

I picked up this boat a couple months ago. It's a 1975 Avenger Jet Boat with a 454 chevy and a Berkley pump.

This P.O.S. 454 is not doing it for me, and I've had nothing but problems with it. Runs like crap (imo), and I can only get ~47 mph out of it.

So.....being no stranger to LSx swapping, I am REALLY contemplating stuffing a 6.0L LQ9 in it.

Now I am just thinking out loud here, so bear with me, and feel free to chime in...

Here's each system broken down:

Jet Pump: The bellhousing from the BBC should work on the LS block, right? Could I re-use the big block flywheel, or is it different? I would need a stainless impeller that would withstand the increased HP and RPM of the LS.

Cooling: I'd need to find a waterpump block-off since the engine is cooled by water from the jet-pump.

Exhaust: Two options here...could either pick up the Indmar water jacketed manifolds/risers, or flip over some longtube headers and go over the transom with them. How the hell do I run a wideband O2 with water injected exhaust??

Engine mounting: Not an issue. I will fabricate some mounts.

Engine accessories: My bellhousing has the starter mounted on top of it, which is kind of weird. May re-use that if possible, or maybe use the automotive starter. Will not have a water pump, AC compressor, or power-steering pump. How can I just run the alternator off the crank? Lots of idler pulleys?

Wiring/Tuning: Probably just have Speartech build me a custom harness for this application. How will the engine react to not having a trans attached? (no VSS, etc) I have EFI Live, so I'm pretty much set for tuning it myself.

Fuel System: More than likely will just get a Walbro inline like I did for my '69. Works great! I will have to run a return though, since the boat currently does not have one.

I welcome any comments and/or advice! Am I missing anything?

Thanks,

J

Last edited by Compressor Surge; 03-21-2010 at 11:01 AM.

#2

TECH Apprentice

iTrader: (1)

Join Date: Apr 2007

Location: FL

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

Have you looked at the impeller yet? 47mph seems a bit low. It may be something as simple as changing the impeller pitch and/or revising the design of your intake grate. Either that or you're simply not turning enough RPM.

Maybe it's just a blessing in disguise too, that boat would look sweet w/ an LSx in it.

Maybe it's just a blessing in disguise too, that boat would look sweet w/ an LSx in it.

#4

it has no way to change the impeller since its a jet boat, you might want to have the pump checked out i have a buddy that just got his jet boat done but they are ford people its got a like a stroked 460 and they had there pump build and his boat will run in the 90s

#5

sawzall wielding director

iTrader: (4)

What RPM are you spinning with the 454? Are you getting that speed from the boat speedo or a GPS?

Anyway the bellhousing will but won`t work. It bolts right to the back of a LS series block except for one bolt that you can just leave out. However the BBC flywheel will not work because the bolt pattern on an LS crank is different. Thats where the problem lies. From the age and pics of your boat I am almost positive it has the short 6.75" rockwell driveline that was used on almost all boats of that age. The problem is that it bolts to the crank flange so it will not bolt onto a LS crank. The rockwell driveline was made specifically for jetboats and was specific to each engine crank flange bolt pattern. They are no longer made and the new style drivelines are universal with an adapter/spacer.....so you have to move the engine 2" forward = your rear bellhousing will no longer reach the pump. http://www.jetboatperformance.com/in...elineeducation

You can make water pump blockoff plates. Just cut some 1/2" aluminum to the same shape as the gasket, drill and tap it so that barbed fittings will go in.

Exhaust: well you prettymuch have seen the options. I don`t know of too many people running EFI in jets and I don`t know if any of them use O2`s. Two places I would look at are outlaw/eagle (they have built a few LS series powered jet boats) and on the DIY side theres a guy who goes by the name Unchained on http://www.performanceboats.com/html/forums/index.php and he runs EFI, you can find him in the great lakes section and the jet section.

Accys: nothing to it, remove everything but the alt, measure up the belt length and then make a bracket to hold a tensioner against the belt (LT1 tensioners push in against the outside of the belt and are easy to mount ) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

Wiring you could have done or do it yourself. Missing the trans will not hurt anything, just delete the trans stuff in the PCM, just like if the engine was on a dyno.

You will have to change the oil pan, the truck one will not allow the engine to sit low enough. f-body would probably work, heck even the vette batwing pan may fit.

Anyway the bellhousing will but won`t work. It bolts right to the back of a LS series block except for one bolt that you can just leave out. However the BBC flywheel will not work because the bolt pattern on an LS crank is different. Thats where the problem lies. From the age and pics of your boat I am almost positive it has the short 6.75" rockwell driveline that was used on almost all boats of that age. The problem is that it bolts to the crank flange so it will not bolt onto a LS crank. The rockwell driveline was made specifically for jetboats and was specific to each engine crank flange bolt pattern. They are no longer made and the new style drivelines are universal with an adapter/spacer.....so you have to move the engine 2" forward = your rear bellhousing will no longer reach the pump. http://www.jetboatperformance.com/in...elineeducation

You can make water pump blockoff plates. Just cut some 1/2" aluminum to the same shape as the gasket, drill and tap it so that barbed fittings will go in.

Exhaust: well you prettymuch have seen the options. I don`t know of too many people running EFI in jets and I don`t know if any of them use O2`s. Two places I would look at are outlaw/eagle (they have built a few LS series powered jet boats) and on the DIY side theres a guy who goes by the name Unchained on http://www.performanceboats.com/html/forums/index.php and he runs EFI, you can find him in the great lakes section and the jet section.

Accys: nothing to it, remove everything but the alt, measure up the belt length and then make a bracket to hold a tensioner against the belt (LT1 tensioners push in against the outside of the belt and are easy to mount

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.Wiring you could have done or do it yourself. Missing the trans will not hurt anything, just delete the trans stuff in the PCM, just like if the engine was on a dyno.

You will have to change the oil pan, the truck one will not allow the engine to sit low enough. f-body would probably work, heck even the vette batwing pan may fit.

Trending Topics

#8

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, it's an aluminum impeller, and it's a little bit nicked up and whatnot. I know I'm losing some speed from that. I also don't know what cut the impeller is.

I like where your head's at

The rpm is ~4500.....or maybe 5000 rpm. I've come to find out that the tach isn't too accurate. My timing light claimed 3000 rpm when the tach said 3500 while setting the timing. I believe the timing light. The 47 mph is from my GPS. I know better than to believe the pitot "wish-o-meter"  haha

haha

Driveline: Think it would be possible to weld up the existing mounting holes and re-drill / machine it to work with the LS?

Cooling: I've got access to a Bridgeport mill, so I can make the blockoff plates myself.

Accessories: Thanks for the heads up on the pulleys. I will look into that. I will probably just run an LS starter, since my engine bay is open (not too worried about igniting fumes) and it's probably small enough to fit well.

Wiring: You know, I never thought that it would be just like having it on the dyno. That is a great point. I have that covered then.

Good point on the oil pan. Forgot that it has to clear the pump. The F-bod pan has the front sump, correct?

I'm thinking about turbocharging this one if I do it. Running open loop is not a problem. I'm running EFILive COS5 in my 5.3 right now, open loop, speed density. Tuning it with wet exhaust would be the only problem, without assistance from a wideband.

I've been thinking about just stabbing an 8.1 from a pickup in there. Everything *should* work (to my knowledge) like exhaust, engine mounts, bellhousing, flywheel, etc. Then it would have tunable EFI on it, too. The local parts house has an 8.1 in stock. They want $900 for it. Might go look at it and see how bad it is...

Keep the ideas coming guys!!

What RPM are you spinning with the 454? Are you getting that speed from the boat speedo or a GPS?

Anyway the bellhousing will but won`t work. It bolts right to the back of a LS series block except for one bolt that you can just leave out. However the BBC flywheel will not work because the bolt pattern on an LS crank is different. Thats where the problem lies. From the age and pics of your boat I am almost positive it has the short 6.75" rockwell driveline that was used on almost all boats of that age. The problem is that it bolts to the crank flange so it will not bolt onto a LS crank. The rockwell driveline was made specifically for jetboats and was specific to each engine crank flange bolt pattern. They are no longer made and the new style drivelines are universal with an adapter/spacer.....so you have to move the engine 2" forward = your rear bellhousing will no longer reach the pump. http://www.jetboatperformance.com/in...elineeducation

You can make water pump blockoff plates. Just cut some 1/2" aluminum to the same shape as the gasket, drill and tap it so that barbed fittings will go in.

Exhaust: well you prettymuch have seen the options. I don`t know of too many people running EFI in jets and I don`t know if any of them use O2`s. Two places I would look at are outlaw/eagle (they have built a few LS series powered jet boats) and on the DIY side theres a guy who goes by the name Unchained on http://www.performanceboats.com/html/forums/index.php and he runs EFI, you can find him in the great lakes section and the jet section.

Accys: nothing to it, remove everything but the alt, measure up the belt length and then make a bracket to hold a tensioner against the belt (LT1 tensioners push in against the outside of the belt and are easy to mount ) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

Wiring you could have done or do it yourself. Missing the trans will not hurt anything, just delete the trans stuff in the PCM, just like if the engine was on a dyno.

You will have to change the oil pan, the truck one will not allow the engine to sit low enough. f-body would probably work, heck even the vette batwing pan may fit.

Anyway the bellhousing will but won`t work. It bolts right to the back of a LS series block except for one bolt that you can just leave out. However the BBC flywheel will not work because the bolt pattern on an LS crank is different. Thats where the problem lies. From the age and pics of your boat I am almost positive it has the short 6.75" rockwell driveline that was used on almost all boats of that age. The problem is that it bolts to the crank flange so it will not bolt onto a LS crank. The rockwell driveline was made specifically for jetboats and was specific to each engine crank flange bolt pattern. They are no longer made and the new style drivelines are universal with an adapter/spacer.....so you have to move the engine 2" forward = your rear bellhousing will no longer reach the pump. http://www.jetboatperformance.com/in...elineeducation

You can make water pump blockoff plates. Just cut some 1/2" aluminum to the same shape as the gasket, drill and tap it so that barbed fittings will go in.

Exhaust: well you prettymuch have seen the options. I don`t know of too many people running EFI in jets and I don`t know if any of them use O2`s. Two places I would look at are outlaw/eagle (they have built a few LS series powered jet boats) and on the DIY side theres a guy who goes by the name Unchained on http://www.performanceboats.com/html/forums/index.php and he runs EFI, you can find him in the great lakes section and the jet section.

Accys: nothing to it, remove everything but the alt, measure up the belt length and then make a bracket to hold a tensioner against the belt (LT1 tensioners push in against the outside of the belt and are easy to mount

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.

) Your probably going to have to ditch the top mount starter and run a regular LS style starter.Wiring you could have done or do it yourself. Missing the trans will not hurt anything, just delete the trans stuff in the PCM, just like if the engine was on a dyno.

You will have to change the oil pan, the truck one will not allow the engine to sit low enough. f-body would probably work, heck even the vette batwing pan may fit.

haha

hahaDriveline: Think it would be possible to weld up the existing mounting holes and re-drill / machine it to work with the LS?

Cooling: I've got access to a Bridgeport mill, so I can make the blockoff plates myself.

Accessories: Thanks for the heads up on the pulleys. I will look into that. I will probably just run an LS starter, since my engine bay is open (not too worried about igniting fumes) and it's probably small enough to fit well.

Wiring: You know, I never thought that it would be just like having it on the dyno. That is a great point. I have that covered then.

Good point on the oil pan. Forgot that it has to clear the pump. The F-bod pan has the front sump, correct?

I've been thinking about just stabbing an 8.1 from a pickup in there. Everything *should* work (to my knowledge) like exhaust, engine mounts, bellhousing, flywheel, etc. Then it would have tunable EFI on it, too. The local parts house has an 8.1 in stock. They want $900 for it. Might go look at it and see how bad it is...

Keep the ideas coming guys!!

#10

The exhaust is not wet till after the manifolds, manifolds are water jacketed to keep the outside of them cool, if water was injected into the manifolds reversion would draw it into the cylinders and roach the engine.

Indmar should have manifolds with o2 sensors, CARB requires after cat sensors on all 08 and up boats.

If you go with an engine that has any aluminum components you will want to run a closed cooling system, with a heat exchanger to cool anti-freeze that is circulated through the engine by the factory water pump. The water out of the heat exchanger goes into the exhaust and overboard.

Indmar should have manifolds with o2 sensors, CARB requires after cat sensors on all 08 and up boats.

If you go with an engine that has any aluminum components you will want to run a closed cooling system, with a heat exchanger to cool anti-freeze that is circulated through the engine by the factory water pump. The water out of the heat exchanger goes into the exhaust and overboard.

#11

TECH Addict

iTrader: (12)

2nd post i've read this week about an LSx boat. Coincidence i was going to start such a build this summer? I think not. I knew it was only a matter of time. Lots of great info guys.

The 8.1 out of the trucks ive heard was designed on BBC platform but dont know that it would be much of a step up for you. Yes EFI would be great but then tuning it would be no so great. I say try to get the LSx build going. A 7000rpm jet boat motor would be pretty awesome man.

The 8.1 out of the trucks ive heard was designed on BBC platform but dont know that it would be much of a step up for you. Yes EFI would be great but then tuning it would be no so great. I say try to get the LSx build going. A 7000rpm jet boat motor would be pretty awesome man.

#12

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Keep it coming, guys!

I should have my LQ9 longblock soon. Now the only question is do I stuff it in my '69 C-10 or put it in the boat???

I guess if I put it in the truck, I could always bore out the 5.3 that's in it to a 5.7 and stick that in the boat with a turbo....hmmmm....

I should have my LQ9 longblock soon. Now the only question is do I stuff it in my '69 C-10 or put it in the boat???

I guess if I put it in the truck, I could always bore out the 5.3 that's in it to a 5.7 and stick that in the boat with a turbo....hmmmm....

#13

sawzall wielding director

iTrader: (4)

You would have to pull the bowl to determine the impeller size for sure, it will be stamped into the center of the impeller.

Overachiever, I just finished making a set for my motor, all you really need is a hacksaw and a drill. But I did make this set with a bandsaw and drill press....much nicer to do it that way.

Overachiever, I just finished making a set for my motor, all you really need is a hacksaw and a drill. But I did make this set with a bandsaw and drill press....much nicer to do it that way.I don`t know how much experience you have with jets, but unless your making a ton of power at high rpm you probably won`t spin the engine very fast. I attached a hp/rpm chart for the impellers. Keep in mind that the smaller B, C, D, E impellers are not as efficient. The AA is much better for cruising. My dads taylor had an A impeller in it when we bought it, it would cavitate badly if you tried to launch it hard. After we swapped to the AA it does not cavitate no matter how fast you hit the throttle, and it even increased the fuel mileage.

#14

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Indmar should have manifolds with o2 sensors, CARB requires after cat sensors on all 08 and up boats.

If you go with an engine that has any aluminum components you will want to run a closed cooling system, with a heat exchanger to cool anti-freeze that is circulated through the engine by the factory water pump. The water out of the heat exchanger goes into the exhaust and overboard.

If you go with an engine that has any aluminum components you will want to run a closed cooling system, with a heat exchanger to cool anti-freeze that is circulated through the engine by the factory water pump. The water out of the heat exchanger goes into the exhaust and overboard.

Did you mean any aluminum components when running in salt water, only? The exhaust manifolds and risers on my boat right now are aluminum...so is the jet pump. I will be running in fresh water only. (if the Illinois River can be classified as "fresh" water....LOL)

Lightweight, powerful, efficient, compact.

Well if it is the factory impeller it will be listed on the jet drive ID plate IE: a 12jc-A would be an A impeller and a 12jc-D would be a D impeller. It sounds like there is more than a few things wrong. In that boat 4000 RPM should be a lot faster than 47mph. Unless you have an E impeller and the engine is just very sick. My dads taylor jetboat spins ~4000 max with a AA impeller and that is 68 gps, it has a stocker 454 that we pulled out of an ambulance. Only thing we did was rings and stuck a cam in it. And his taylor is a bit heavier than your boat, its a 20'er, enclosed engine, and the taylors were laid up quite heavy.

I will investigate tonight exactly what kind of driveline and flywheel or flexplate I have.

I will investigate tonight exactly what kind of driveline and flywheel or flexplate I have. I don`t know how much experience you have with jets, but unless your making a ton of power at high rpm you probably won`t spin the engine very fast. I attached a hp/rpm chart for the impellers. Keep in mind that the smaller B, C, D, E impellers are not as efficient. The AA is much better for cruising. My dads taylor had an A impeller in it when we bought it, it would cavitate badly if you tried to launch it hard. After we swapped to the AA it does not cavitate no matter how fast you hit the throttle, and it even increased the fuel mileage.

LOL.

LOL. Mine doesn't cavitate at all when I wood it. However, I'll need to buy a stainless impeller to handle the rpm and hp that I'd be throwing at it with an angry LS. Do you know of a good place to find used stainless impellers? I don't have $1300 right now to drop on a brand new one.

#16

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Also, here's an interesting thread I found, regarding marinizing an LS1.

http://www.boatdesign.net/forums/showthread.php?t=9524

http://www.boatdesign.net/forums/showthread.php?t=9524

#17

TECH Apprentice

Thread Starter

iTrader: (21)

Join Date: Dec 2005

Location: Mackinaw, IL

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

6.0L marine engines...complete.

http://www.waspaust.co.nz/Marine%20Engines.html

Marine manifolds for Holden Commodores:

http://www.waspaust.co.nz/Marine%20Manifolds.html

http://www.waspaust.co.nz/Marine%20Engines.html

Marine manifolds for Holden Commodores:

http://www.waspaust.co.nz/Marine%20Manifolds.html

#20

well for the time being you could tune up that big block. Edelbrock carbs suck. I bet an 850 holley and a good intake would wake that thing up like crazy, every engine dyno test ive ever seen the first thing they do on a big block is upgrade the carb, and the first thing I do is ditch the edelbrock carbs. That intake mani is sure to be killing it as well, could be about 75% of the problem right there. They are OK on a daily driver but crap for RPM. Also you might upgrade the ignition system, from new plugs to an upgraded module in the HEI. All these things will give you more RPM.