8.8 Build

#1

TECH Apprentice

Thread Starter

iTrader: (106)

Join Date: Jun 2007

Location: Eastland,Texas

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

Here is my attempt at building a low cost rear.

First off out with the old 10 bolt

I started with a 8.8 housing out of any 79-98 mustang then i welded the 10 bolt bracket to the housing . With the pinion set at 0 i welded the lower control arms on to the rear at 15 degrees negative and 0 for the spring perches. I cant remember what the measurements were between the lca but i think anyone attempting to do this can find out.

I got a great deal on a ford 31 slpine trackloc carrier and 410 motive gears for 150 shipped. I went with moser 31 spline axles in stock 94 to 98 mustang length and with no abs rings for $290 shipped and this make the total width of the rear 61" 4" narrower the a stock 10 bolt!

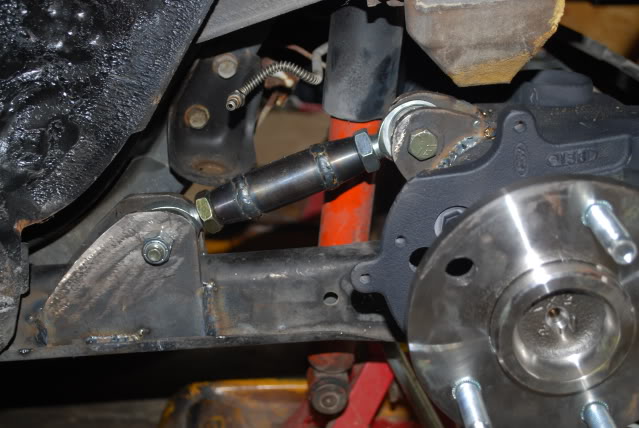

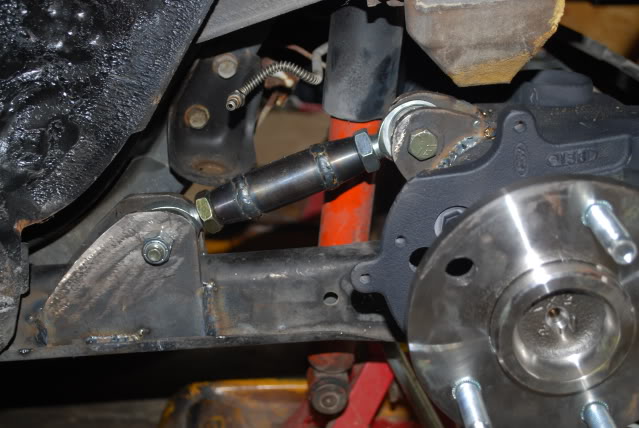

I'm going to start out using a short arm ladder bar setup welded to the lca,but maybe i will make a torque arm mount this winter. I started with 1" cold formed seamless dom tubing and 3/4 weld in bungs,3/4 forged qa1 rod ends for the links to control axle wrap and pinion angle. Then just some mild steel for the brackets cut and drilled the way i needed them to fit around the rod ends!

Now for the brakes i used stock gt brakes from a 94 model. I honed out the bolt holes a little larger on rotors to accept the 5x4 3/4 pattern. Then i modified the emergency cable brackets and lines to make the emergency brake work it hard to see but i cut all of the bracket off accept the side shown. I cut the end of the cable also the part that goes over the hook on the ls1 brake setup so that there is just a small piece left to hook on the mustang style brake setup

Now for wheels i went with billet specialties in 15x3.5 in the front and 15x10 with 5.5 backspacing look at the clearance of the mustang brakes

The stock driveshaft works with this rear with a crossover u joint a precision 355 found at oreillys

Now for some pics of the rear in the car with loaded suspension nothing on the ground yet i'm still working to get to that point

I will say i think this is a perfect fit for what i wanted

now i will run the price of everything i bought

8.8 housing 50 bucks

axles from moser 290 shipped

410 gears and 31 spline carrier 150 shipped

misc. ladder bar setup 80 bucks

brakes from junk mustang with backing plates 40 bucks

u joint from oreillys 20 bucks

and i had master install kit left over from my mustang days

total 630 dollars - 275 that i got for the stock 10 bolt making this build cost me 355 bucks and some labor! you cant hardly do a gear change for that

First off out with the old 10 bolt

I started with a 8.8 housing out of any 79-98 mustang then i welded the 10 bolt bracket to the housing . With the pinion set at 0 i welded the lower control arms on to the rear at 15 degrees negative and 0 for the spring perches. I cant remember what the measurements were between the lca but i think anyone attempting to do this can find out.

I got a great deal on a ford 31 slpine trackloc carrier and 410 motive gears for 150 shipped. I went with moser 31 spline axles in stock 94 to 98 mustang length and with no abs rings for $290 shipped and this make the total width of the rear 61" 4" narrower the a stock 10 bolt!

I'm going to start out using a short arm ladder bar setup welded to the lca,but maybe i will make a torque arm mount this winter. I started with 1" cold formed seamless dom tubing and 3/4 weld in bungs,3/4 forged qa1 rod ends for the links to control axle wrap and pinion angle. Then just some mild steel for the brackets cut and drilled the way i needed them to fit around the rod ends!

Now for the brakes i used stock gt brakes from a 94 model. I honed out the bolt holes a little larger on rotors to accept the 5x4 3/4 pattern. Then i modified the emergency cable brackets and lines to make the emergency brake work it hard to see but i cut all of the bracket off accept the side shown. I cut the end of the cable also the part that goes over the hook on the ls1 brake setup so that there is just a small piece left to hook on the mustang style brake setup

Now for wheels i went with billet specialties in 15x3.5 in the front and 15x10 with 5.5 backspacing look at the clearance of the mustang brakes

The stock driveshaft works with this rear with a crossover u joint a precision 355 found at oreillys

Now for some pics of the rear in the car with loaded suspension nothing on the ground yet i'm still working to get to that point

I will say i think this is a perfect fit for what i wanted

now i will run the price of everything i bought

8.8 housing 50 bucks

axles from moser 290 shipped

410 gears and 31 spline carrier 150 shipped

misc. ladder bar setup 80 bucks

brakes from junk mustang with backing plates 40 bucks

u joint from oreillys 20 bucks

and i had master install kit left over from my mustang days

total 630 dollars - 275 that i got for the stock 10 bolt making this build cost me 355 bucks and some labor! you cant hardly do a gear change for that

#3

10 Second Club

iTrader: (21)

Join Date: Nov 2001

Location: Olive Branch MS/Memphis

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Great work! Can you tell any difference now that you don't have a torque arm. I have always wanted to try a mini-ladder bar setup like you have there.

Why don't you get started building one for me!

Why don't you get started building one for me!

#7

TECH Apprentice

Thread Starter

iTrader: (106)

Join Date: Jun 2007

Location: Eastland,Texas

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

If you can weld and have common knowledge you can do this. It's really not that hard just putting parts together the hard parts done someone to figure out all the problems with the swap which i already did all the research for what you need. but i am still waiting on how good the ladder bar setup is going to work. A lot of people on here says it works but hits the tires a little hard so ill see how that works out.

Trending Topics

#8

TECH Junkie

iTrader: (34)

If you can weld and have common knowledge you can do this. It's really not that hard just putting parts together the hard parts done someone to figure out all the problems with the swap which i already did all the research for what you need. but i am still waiting on how good the ladder bar setup is going to work. A lot of people on here says it works but hits the tires a little hard so ill see how that works out.

#10

TECH Apprentice

Thread Starter

iTrader: (106)

Join Date: Jun 2007

Location: Eastland,Texas

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

Ok drove the car yesterday and i will say that i am impressed! It hooked a lot better then my old rear and this one has 4.10 in it. No wheel hop what so ever! also i am not running a rear sway bar at the moment to see how that works. The car holds the road and goes straight down the road under acceleration i am real happy with how it turned out. Oh for those that are worried about how noisy this set up is on the street i will say that it's quiet i have some crappy cell pics of the car down off the jack stands

#12

TECH Apprentice

Thread Starter

iTrader: (106)

Join Date: Jun 2007

Location: Eastland,Texas

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

When i drove it yesterday the body didn't seem to roll like i thought it would, and that's without a rear or front sway bar i leaving them off for now. I will say that this rear is lighter than a 10 bolt rear and a hell a lot stronger!

#17

TECH Apprentice

Thread Starter

iTrader: (106)

Join Date: Jun 2007

Location: Eastland,Texas

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

I took all the measurements from my 10 bolt and set it up that way. The panhard bar is in the same location as stock, so are the lca mounts the narrowed housing means that the lca mounts and spring mounts move closer to the backing plate. No measurement has changed from stock just the width of the housing

but i can always upgrade that for 100 bucks

but i can always upgrade that for 100 bucks