58mm TB idle air circuit & split BLMs. Why is it different than a OEM TB?

#1

I am chasing down an on again, off again cell 16 split BLM. One minute they are close +/- 3 points then they go huge split for no apparant reason.

The car normally idles perfect with 35-45 points on the IAC. I also have the bypass hole drilled in the idle circuit path because without it, the IAC points were too high. Also there are no obvious vacuum or exhaust leaks to be found.

I am focusing on the idle circuit of my BBK 58mm TB which is much different than the idle circuit on the OEM TB.

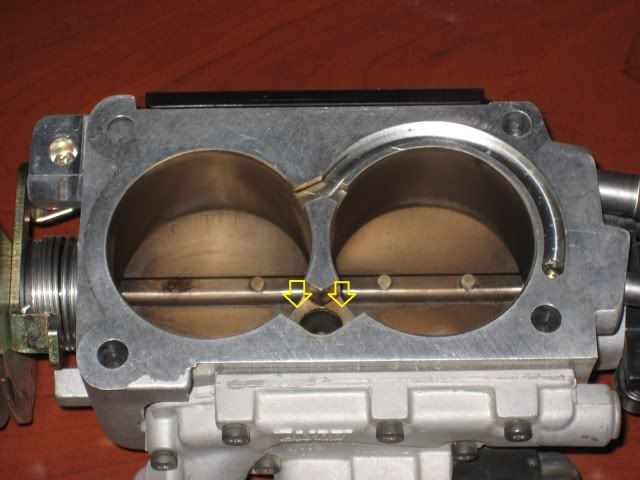

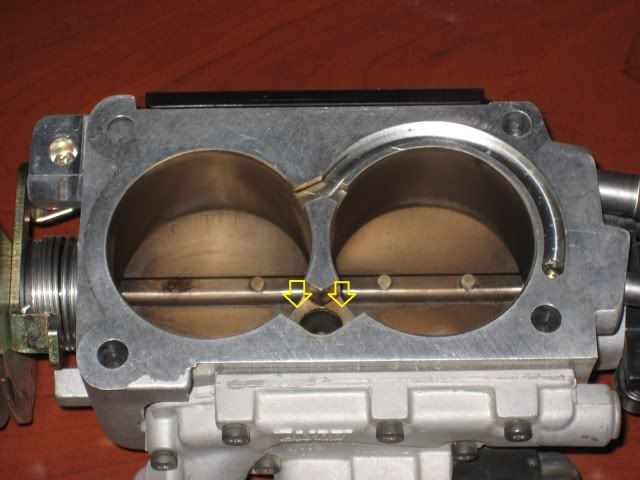

My BBK 58mm TB allows the idle air stream to enter the intake at the port large port openings (behind the butterflies) because of a pair of machined paths (yellow arrows) not found on the stocker:

Again an OEM TB does not have these machined paths and forces all idle air into the small bottom hole on the front of the LT1 intake which is then evenly distributed to all 8 ports through the paths inside the intake.

Why is this not the case for an aftermarket 58mm TB?

I have googled myself silly and have found that many with this TB have the same problem and they blamed the NON OEM idle circuit. I also ran across this writeup where the guy installed tubing to force the aftermarket TB to use the OEM idle circuit:

http://www.noid.org/~lj/PCM%20Tutorial/SplitBLMinfo.htm

I have never found a reason for the difference in the idle circuits on these aftermarket 58mm TB's.

Anyone have any success modding their idle circuit back to stock like to address split BLMs?

Comments?

The car normally idles perfect with 35-45 points on the IAC. I also have the bypass hole drilled in the idle circuit path because without it, the IAC points were too high. Also there are no obvious vacuum or exhaust leaks to be found.

I am focusing on the idle circuit of my BBK 58mm TB which is much different than the idle circuit on the OEM TB.

My BBK 58mm TB allows the idle air stream to enter the intake at the port large port openings (behind the butterflies) because of a pair of machined paths (yellow arrows) not found on the stocker:

Again an OEM TB does not have these machined paths and forces all idle air into the small bottom hole on the front of the LT1 intake which is then evenly distributed to all 8 ports through the paths inside the intake.

Why is this not the case for an aftermarket 58mm TB?

I have googled myself silly and have found that many with this TB have the same problem and they blamed the NON OEM idle circuit. I also ran across this writeup where the guy installed tubing to force the aftermarket TB to use the OEM idle circuit:

http://www.noid.org/~lj/PCM%20Tutorial/SplitBLMinfo.htm

I have never found a reason for the difference in the idle circuits on these aftermarket 58mm TB's.

Anyone have any success modding their idle circuit back to stock like to address split BLMs?

Comments?

#2

TECH Veteran

iTrader: (246)

There have been people who made a plate that will go in between that arrow pointing area and spot weld the plate in or even glue it on. To create a no noise problem and reduce iac points. ALso why did you drill it out, sometimes you can tune it good enough to get the iac points down.

#3

There have been people who made a plate that will go in between that arrow pointing area and spot weld the plate in or even glue it on. To create a no noise problem and reduce iac points. ALso why did you drill it out, sometimes you can tune it good enough to get the iac points down.

#4

TECH Fanatic

iTrader: (7)

http://members.***.net/chipsbyal/page/idle/tbi.htm

#6

#7

Here are some pics of my TB mod:

I have done some tweaking on the blades and found the best position I could. The blades are nearly completely closed and the TPS voltage is .71V and the IAC counts are very steady at 35-38 points. I also raised the idle RPM from 800 to 950 RPM.

The TB mod seems to have made the cell 16 BLM's more consistant but they are still clearly split.

They seem to be planted at 113/130 after some quick road testing.

I am going to do some more testing to see if they stay like this.

I am trying to learn about the individual cylinder trim setting to see if they can be revised to fix the split.

My current (tuner tweaked) individual cylinder trims at idle are:

1 - 1.02

8 - 0.98

4 - 0.98

3 - 1.01

6 - 1.01

5 - 0.98

7 - 0.99

2 - 1.02

FTR, the OEM stock individual cylinder trims at idle are:

1 - 1.06

8 - 0.95

4 - 0.95

3 - 1.00

6 - 0.98

5 - 0.95

7 - 0.94

2 - 1.08

My question.

When the left cell 16 BLM is < than 128, do the 1,3,5,7, individual fuel trim numbers need to be slightly increased or decreased to try to force them closer to 128?

My assumption is they should be slightly decreased. If this is correct, I might try reducing 1,3,5,7, by 5% each and see what the left BLM does. Hopefully, it moves from 113 and goes higher, or closer to 128 or so.

I am interested in hearing someone chime in on the individual bank fuel trims and whether there is hope for fixing the split.

I have done some tweaking on the blades and found the best position I could. The blades are nearly completely closed and the TPS voltage is .71V and the IAC counts are very steady at 35-38 points. I also raised the idle RPM from 800 to 950 RPM.

The TB mod seems to have made the cell 16 BLM's more consistant but they are still clearly split.

They seem to be planted at 113/130 after some quick road testing.

I am going to do some more testing to see if they stay like this.

I am trying to learn about the individual cylinder trim setting to see if they can be revised to fix the split.

My current (tuner tweaked) individual cylinder trims at idle are:

1 - 1.02

8 - 0.98

4 - 0.98

3 - 1.01

6 - 1.01

5 - 0.98

7 - 0.99

2 - 1.02

FTR, the OEM stock individual cylinder trims at idle are:

1 - 1.06

8 - 0.95

4 - 0.95

3 - 1.00

6 - 0.98

5 - 0.95

7 - 0.94

2 - 1.08

My question.

When the left cell 16 BLM is < than 128, do the 1,3,5,7, individual fuel trim numbers need to be slightly increased or decreased to try to force them closer to 128?

My assumption is they should be slightly decreased. If this is correct, I might try reducing 1,3,5,7, by 5% each and see what the left BLM does. Hopefully, it moves from 113 and goes higher, or closer to 128 or so.

I am interested in hearing someone chime in on the individual bank fuel trims and whether there is hope for fixing the split.

Trending Topics

#9

Right now I have the blades completely closed.

Finally getting some good results now.

My previously massively split cell 16 BLM's have gone from 110/138 to 125/125 on cell 16 by adjusting the individual cylinder trims at idle. This is driving around the block several times and they stayed rock solid. I then turned the motor off, waited five minutes, started it back up and drove again and the numbers remained very close +/- a point or two.

My current (tweaked) individual cylinder trims @ idle are:

1 - 0.97

8 - 1.02

4 - 1.03

3 - 0.95

6 - 1.03

5 - 0.91

7 - 0.88

2 - 1.08

Odd bank average is 0.93 and the even bank is average 1.04. Clearly this re-balancing is needed to get the BLMs balanced.

For reference, stock odd bank average is 1 and even bank is one as well.

I can use the MAF tables to move the 125/125 closer to 128/128.

So what I have done here is manually cut and added a small quantity of fuel via the ICFT's @ idle for idle conditions only. The BLMs are still working but the PCM is not having to work as hard to keep things closer to 128/128. I am assuming that since the banks are now nearly balanced and much closer 128 BLM, then idle conditions are better than before. FTR I am not having any funky idle problems, I am only trying to address the BLM's to more or less polish things up. Once the motor leaves idle conditions, nothing else should be affected by what I have done.

Most believe its the 107 LSA on my cam causing reversion and therefore the split cell 16 BLMs. The rest of the BLMs in the other cells are much closer together and probably considered acceptable. Just the idle cell is messed up. I am confident there are no vacuum or exhaust leaks.

Is this tweaking of the ICFT's @ idle desirable or am I screwing something up here?

Should I just revert back to stock ICFT's @ idle and deal with the severe cell 16 splits?

Finally getting some good results now.

My previously massively split cell 16 BLM's have gone from 110/138 to 125/125 on cell 16 by adjusting the individual cylinder trims at idle. This is driving around the block several times and they stayed rock solid. I then turned the motor off, waited five minutes, started it back up and drove again and the numbers remained very close +/- a point or two.

My current (tweaked) individual cylinder trims @ idle are:

1 - 0.97

8 - 1.02

4 - 1.03

3 - 0.95

6 - 1.03

5 - 0.91

7 - 0.88

2 - 1.08

Odd bank average is 0.93 and the even bank is average 1.04. Clearly this re-balancing is needed to get the BLMs balanced.

For reference, stock odd bank average is 1 and even bank is one as well.

I can use the MAF tables to move the 125/125 closer to 128/128.

So what I have done here is manually cut and added a small quantity of fuel via the ICFT's @ idle for idle conditions only. The BLMs are still working but the PCM is not having to work as hard to keep things closer to 128/128. I am assuming that since the banks are now nearly balanced and much closer 128 BLM, then idle conditions are better than before. FTR I am not having any funky idle problems, I am only trying to address the BLM's to more or less polish things up. Once the motor leaves idle conditions, nothing else should be affected by what I have done.

Most believe its the 107 LSA on my cam causing reversion and therefore the split cell 16 BLMs. The rest of the BLMs in the other cells are much closer together and probably considered acceptable. Just the idle cell is messed up. I am confident there are no vacuum or exhaust leaks.

Is this tweaking of the ICFT's @ idle desirable or am I screwing something up here?

Should I just revert back to stock ICFT's @ idle and deal with the severe cell 16 splits?

Last edited by wrd1972; 01-29-2010 at 10:29 AM.

#10

before the ISSCA site crash....and subsequent loss of YEARS of info there were pics showing what some on this thread did which was fill the chanels (noted in OP's pics) and drill the front as the OEM TB is.

While I may have left some HP on the table (if any) I went back to a stock TB bored to 52mm. driveability and tune issues disappeared.

WTF a aftermarket TB does not follow the path of OEM in this case is a mystery to me...and if there is a "reason" anyone who knows please chime in.

While I may have left some HP on the table (if any) I went back to a stock TB bored to 52mm. driveability and tune issues disappeared.

WTF a aftermarket TB does not follow the path of OEM in this case is a mystery to me...and if there is a "reason" anyone who knows please chime in.

#12

before the ISSCA site crash....and subsequent loss of YEARS of info there were pics showing what some on this thread did which was fill the chanels (noted in OP's pics) and drill the front as the OEM TB is.

While I may have left some HP on the table (if any) I went back to a stock TB bored to 52mm. driveability and tune issues disappeared.

WTF a aftermarket TB does not follow the path of OEM in this case is a mystery to me...and if there is a "reason" anyone who knows please chime in.

While I may have left some HP on the table (if any) I went back to a stock TB bored to 52mm. driveability and tune issues disappeared.

WTF a aftermarket TB does not follow the path of OEM in this case is a mystery to me...and if there is a "reason" anyone who knows please chime in.

#17

well your adjusting your individual cylinder fuel trims slightly theyre set sequential stock for fuel econemy but anywhere after 1%tps it goes to batch. ireally dont know how to explain it better

#18

i was just doing my tb 58mm pro products set the blades to get 36 38 counts and my trims came in all by themselves !!my tps is set .635mvs and my trims settled at 126-128 my problem is the timing is jumping around between 36 39 degrees and wont settle down its also pushing the map around and causeing some surge issues,

#19

10 Second Club

iTrader: (2)

diggin this one up from the dead, but has anyone found a solution to this? My LTFT's are split +25 on B2 and -13 on B1! As soon as you rev the engine they even out but one side is always higher then the other. While driving the STFT's are right on 0.0 but the LTFT's are different. 58mm PP TB with mod to IAC passage to direct air into the IAC hole in intake, new AC O2's, no vacuum leaks. Seems to run fine but sometimes pops in exhaust on decel and between gears. PCMFORLESS tune.

More info on my setup here:

https://ls1tech.com/forums/lt1-lt4-m...issue-idk.html

More info on my setup here:

https://ls1tech.com/forums/lt1-lt4-m...issue-idk.html

#20

TECH Apprentice

iTrader: (3)

Join Date: Jul 2008

Location: Morinville, Alberta, Canada

Posts: 374

Likes: 0

Received 0 Likes

on

0 Posts

I had to fill the open are with a insert and drill a small hole like factory to get mine to idle properly. Granted im running a fairly stout cam(228/236 .600/.600 110lsa), but it made a WORLD of difference in how the car idled.