Trick Flow/383 Build/T56 Swap+PICS & NUMBERS

#1

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

Parts are starting to come in...

383/T56 swap, rods and tranny will be here on monday then the rotating assembly is off to the machine shop. My block has been prepped and fit with 4 bolt splayed caps so hopefully I will be able to pick up the block within 2 weeks. I should have the t56 mocked up by then...

383/T56 swap, rods and tranny will be here on monday then the rotating assembly is off to the machine shop. My block has been prepped and fit with 4 bolt splayed caps so hopefully I will be able to pick up the block within 2 weeks. I should have the t56 mocked up by then...

Last edited by JB_97ws6TA; 05-05-2010 at 07:44 PM. Reason: clarity

#7

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

Rods came in today...

Just got back from dropping everything off at the machine shop. I pulled the cam and timing set out of my car over the weekend so it is ready for assembly. I was told I will have my motor back by next friday, I still need to order the oil pan, pickup, and pump. Transmission delivery got pushed back until wednesday so I will try and mock that up and get the wiring done this weekend.

Just got back from dropping everything off at the machine shop. I pulled the cam and timing set out of my car over the weekend so it is ready for assembly. I was told I will have my motor back by next friday, I still need to order the oil pan, pickup, and pump. Transmission delivery got pushed back until wednesday so I will try and mock that up and get the wiring done this weekend.

Trending Topics

#8

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

It is a small cam but it is an emissions legal street car that may see the track twice a year. It made good power on the stock shortblock and it also made the throttle response very snappy so I think it will be a good fit, make good power, and have close to stock drivability with alot more torque

#10

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

2 Bolt block with splayed 4 bolt caps

Callies Racemaster 3.75 4340 crank

Compstar 6.000 4340 H Beams

Mahle -16cc Reverse Dome Pistons

Clevite H Series Bearings

Lunati 60121 219/227 @.050

Decked to .005 with a .039 compressed gasket thickness

10.9:1 SCR

8.9:1 DCR

.044 quench

Callies Racemaster 3.75 4340 crank

Compstar 6.000 4340 H Beams

Mahle -16cc Reverse Dome Pistons

Clevite H Series Bearings

Lunati 60121 219/227 @.050

Decked to .005 with a .039 compressed gasket thickness

10.9:1 SCR

8.9:1 DCR

.044 quench

#14

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

tranny showed up tonight finally after a couple of issues with the freight company

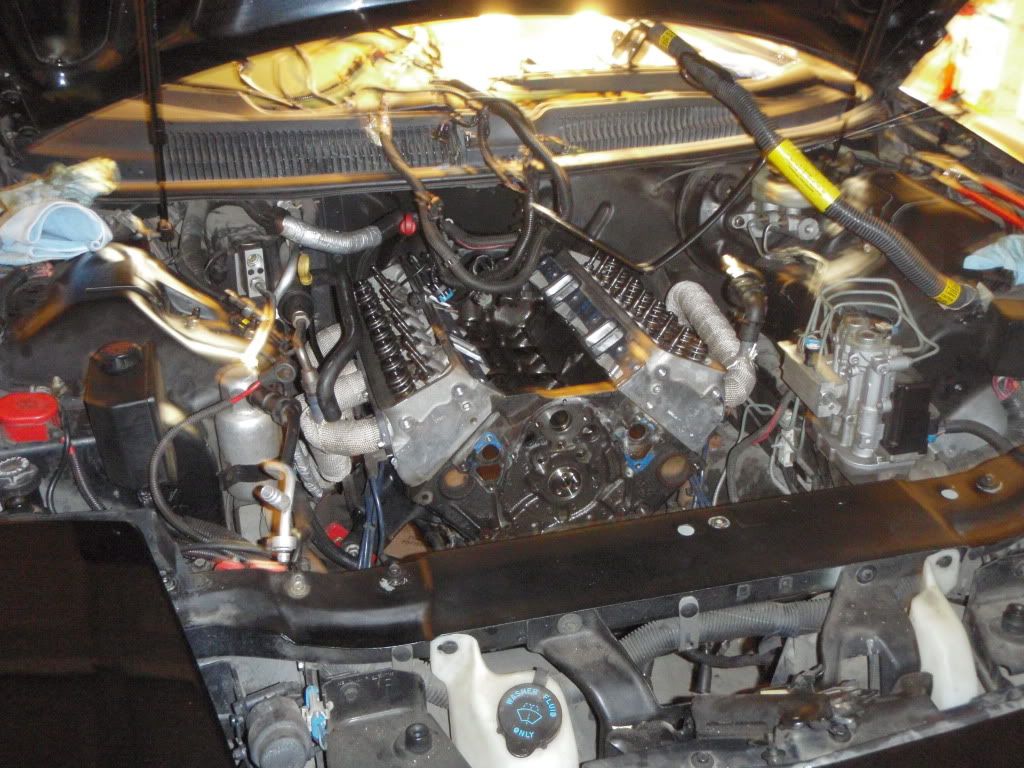

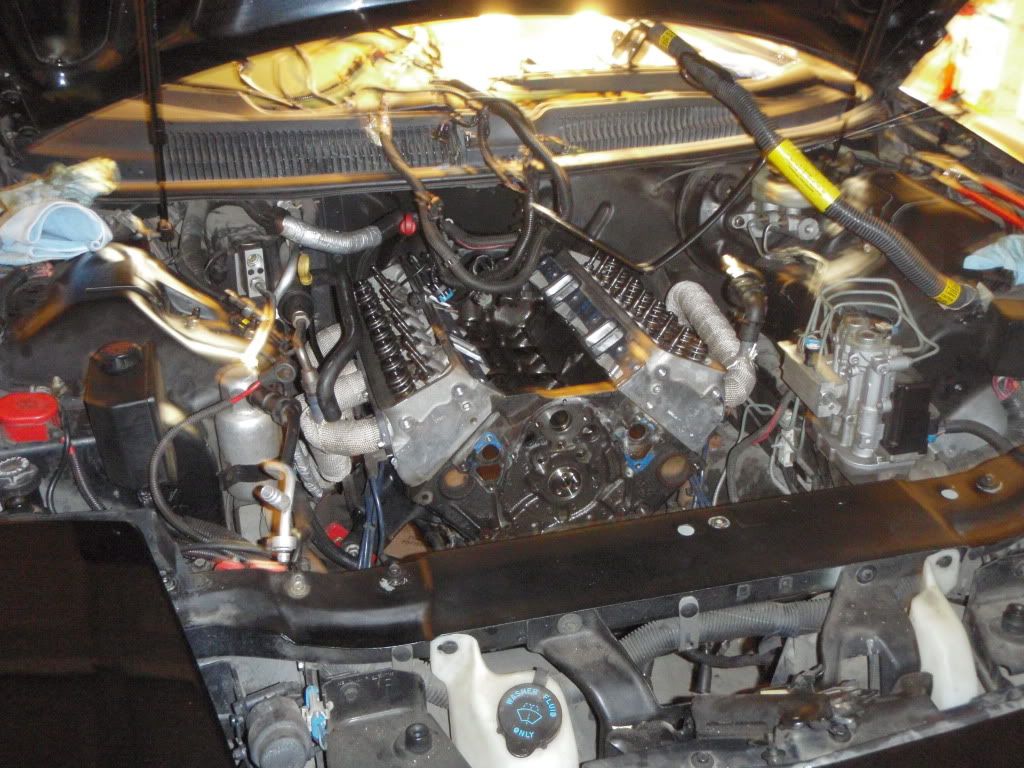

Here is how the car sits now, originally the plan was to mock up the t56 on the old motor and do the wiring, install the pedals, and cut the hole for the shifter. I was planning on using the lower boot as a rough template and leave a 3/4 inch lip but I don't have a lower boot at the moment so I will have to wait for that I guess. I also don't have the hydraulics so it is kind of hard to cut the hole in the firewall for the slave without physically seeing the slave. I understand it is ~1 5/8" hole but is it directly centered in between the mounting holes that the u-bolt goes through? The ceiling in my garage is pretty low so I am definately going to have to remove the hood and even after that I am still a little concerned about the clearance but the intake and valve covers and pretty much everything else is removed and out of the way so it shouldn't be that big of a deal. I was going to leave the intake off until I am ready to fire it anyhow just so I can prime the pump immediately before initial start up. Sorry for the novel but I am hoping that someone out there can give me some info to help me along so I a not sitting on my thumbs waiting for the rest of the tranny parts to come in. Thanks

Here is how the car sits now, originally the plan was to mock up the t56 on the old motor and do the wiring, install the pedals, and cut the hole for the shifter. I was planning on using the lower boot as a rough template and leave a 3/4 inch lip but I don't have a lower boot at the moment so I will have to wait for that I guess. I also don't have the hydraulics so it is kind of hard to cut the hole in the firewall for the slave without physically seeing the slave. I understand it is ~1 5/8" hole but is it directly centered in between the mounting holes that the u-bolt goes through? The ceiling in my garage is pretty low so I am definately going to have to remove the hood and even after that I am still a little concerned about the clearance but the intake and valve covers and pretty much everything else is removed and out of the way so it shouldn't be that big of a deal. I was going to leave the intake off until I am ready to fire it anyhow just so I can prime the pump immediately before initial start up. Sorry for the novel but I am hoping that someone out there can give me some info to help me along so I a not sitting on my thumbs waiting for the rest of the tranny parts to come in. Thanks

#18

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

Well I got a little bit more done today, not as much as I would like to but progress regardless...

I pulled the seats and steering column and installed the pedals. Although I am a bit confused as to why there is another mount on the clutch pedal for what I don't know. I don't have a photo of it but I have heard that the LS1 pedals have a pring assisted pedal return and if that is the case then I did not get the spring...

My next step is to cut the hols in the floor for the shifter but I have no idea how large it needs to be so if someone has some dimensions of the hole I would REALLY appreciate it. Otherwise I am going to have to wait for the lower shift boot and go off of that

I also managed to wrangle the wiring harness out of it so the name of the game now is wiring the harness and the interior

Thw old lady really likes the fact that I am using the spare bedroom as a storage shed/workshop but I am sure she will get over it.

Also, I am on the fence obout what to use to cut the hole for the shifter. I left the carpet and back seats in so I do not want to use a cut off wheel and run the risk of burning anything. Sawzall seems like it would make a mess out of everything as they tend to do whatever I don't want them to do. I toyed around with the idea of trying to find a metal blade for a jig saw but I don't know how well that would work so I guess my question is what would you do??

I pulled the seats and steering column and installed the pedals. Although I am a bit confused as to why there is another mount on the clutch pedal for what I don't know. I don't have a photo of it but I have heard that the LS1 pedals have a pring assisted pedal return and if that is the case then I did not get the spring...

My next step is to cut the hols in the floor for the shifter but I have no idea how large it needs to be so if someone has some dimensions of the hole I would REALLY appreciate it. Otherwise I am going to have to wait for the lower shift boot and go off of that

I also managed to wrangle the wiring harness out of it so the name of the game now is wiring the harness and the interior

Thw old lady really likes the fact that I am using the spare bedroom as a storage shed/workshop but I am sure she will get over it.

Also, I am on the fence obout what to use to cut the hole for the shifter. I left the carpet and back seats in so I do not want to use a cut off wheel and run the risk of burning anything. Sawzall seems like it would make a mess out of everything as they tend to do whatever I don't want them to do. I toyed around with the idea of trying to find a metal blade for a jig saw but I don't know how well that would work so I guess my question is what would you do??

#19

TECH Enthusiast

iTrader: (1)

Join Date: Dec 2002

Location: Long Island NY

Posts: 530

Likes: 0

Received 0 Likes

on

0 Posts

I've done a few T56 swaps, for the wiring I generally left the wiring in the car and just spliced/soldered the couple necessary wires.

For cutting the hole I've always used a dremel with a "heavy duty" cut off wheel. Just buy the little container as you'll go through a few. The dremel allows you to have a ton of control and it goes slow enough your not going to have to worry about making a mistake. For final finishing I've always used multiple course sanding drums on a dremel. It goes slow enough that you really have to try to mess something up. For the hole you want to start around the area that the raised bracket with the hole punched in the middle is and then cut larger until you have a hole just big enough to drop a shifter onto the transmissions mounting face. I've always cut the hole after the T56 is in place to avoid cutting too big.

To install the t56... I've never had any luck stabbing a motor on the input shaft, I've tried and failed multiple times. If you're already replacing the motor do yourself a favor and install the motor and transmission as an assembly, or put in the motor and then put in the transmission. Cut the hole afterwards, make sure you tape up the hole in the top of the t56 before you install it so you don't get metal in the transmission.

You're really going to need the slave to cut the hole in the firewall. There isn't a lot of flange around the hydraulics to seal the hole in the firewall and you can't really afford to have the hole be too big without having to use a ton of silicone and risk having it open up later on from heat and time.

If you're limited on head room I would really suggest installing everything from the bottom. Take out the front cradle, transmission, suspension and all, yank it out from under the car. When I couldn't get the car high enough with jackstands I've wrapped a chain onto the upper radiator support and lifted it with an engine hoist.

then drop the motor on the new cradle, bolt up the transmission and torque the bolts with ease and engage the shift fork with no problem as well as put on any headers, spark plugs, plug wires etc with no issues while it's out of the car. then plop everything in the car.

For cutting the hole I've always used a dremel with a "heavy duty" cut off wheel. Just buy the little container as you'll go through a few. The dremel allows you to have a ton of control and it goes slow enough your not going to have to worry about making a mistake. For final finishing I've always used multiple course sanding drums on a dremel. It goes slow enough that you really have to try to mess something up. For the hole you want to start around the area that the raised bracket with the hole punched in the middle is and then cut larger until you have a hole just big enough to drop a shifter onto the transmissions mounting face. I've always cut the hole after the T56 is in place to avoid cutting too big.

To install the t56... I've never had any luck stabbing a motor on the input shaft, I've tried and failed multiple times. If you're already replacing the motor do yourself a favor and install the motor and transmission as an assembly, or put in the motor and then put in the transmission. Cut the hole afterwards, make sure you tape up the hole in the top of the t56 before you install it so you don't get metal in the transmission.

You're really going to need the slave to cut the hole in the firewall. There isn't a lot of flange around the hydraulics to seal the hole in the firewall and you can't really afford to have the hole be too big without having to use a ton of silicone and risk having it open up later on from heat and time.

If you're limited on head room I would really suggest installing everything from the bottom. Take out the front cradle, transmission, suspension and all, yank it out from under the car. When I couldn't get the car high enough with jackstands I've wrapped a chain onto the upper radiator support and lifted it with an engine hoist.

then drop the motor on the new cradle, bolt up the transmission and torque the bolts with ease and engage the shift fork with no problem as well as put on any headers, spark plugs, plug wires etc with no issues while it's out of the car. then plop everything in the car.

#20

TECH Fanatic

Thread Starter

iTrader: (6)

Join Date: Oct 2007

Location: Central Valley, CA

Posts: 1,119

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the advice! I wasn't sure if the dremel was going to have enough to get through it but I think I will go that route! I am a little hesitant to grab it by the radiator support but I think as long as nothing hangs up and it is just lifting the body it should be ok. I was going to leave the car on jackstands and drop the motor and tranny using jacks then use the cherry picker to lift the body the rest of the way which shouldn't be more than 6 inches I would think. I have the car off the ground pretty good right now and the intake, accessories, and valve covers are off the motor so hopefully I will have some luck there.