Textralia Twin Disk Slips Off Idle

#21

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Also, if you think about it, what is that seal/gasket sealing? Nothing! It's just there to take up space. The input shaft has it's own oil seal in the case. That was probably installed because the pedal was to close to the floor and no I have never seen an gasket/seal there in that fashion unless it was a shim.

#25

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

The clutch does have it's disc's installed and the pressure plate it torqued down? Clutch is assembled correctly and to spec? I'm not trying to insult you. Just trying to cover all the bases.

#26

https://ls1tech.com/forums/manual-tr...-pictures.html

Turns out the seller of the clutch didn't have disks aligned right though. I also cannot get a hold of anyone at textralia and honestly am not dealing with it after tomorrow. I know how to install a clutch and my worn out z-grip was working fine a few days ago and only thing changed was clutch so it must be the clutch.

Here is his pic:

#28

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Disc alignment won't make a differance as far as the measurments go. It may slightly affect engagment and how it wears but that's about it. I honestly don't know what to tell you though. Sorry I could be of any help.

#29

I have no idea whats going on and seller refuses to take pos back.....I cannot talk to anyone at textralia and am going to wait until tomorrow to try and talk to them and if not I am going to buy a new clutch and take seller to court. I wish textralia would answer the damn phone.

Previous owner also had engagement problems but said it was due to a shim.....I found his post after buying his clutch that I was told had 100 miles on it...... but obviously something isn't right

#30

TECH Junkie

iTrader: (17)

ive had 3 specs and if memory serves that is what one of my old shims looked like, kinda a compressed paper material. the later shims i got were metal. its not a seal

although im not sure thats your problem, its a place to start

although based on your no shim measurements i think there may be an issue with the clutch if your sure the slave is fully compressed when your measuring. maybe loosen the bleeder to make it easier to fully compress

shitty

although im not sure thats your problem, its a place to start

although based on your no shim measurements i think there may be an issue with the clutch if your sure the slave is fully compressed when your measuring. maybe loosen the bleeder to make it easier to fully compress

shitty

Last edited by Tally TransAm; 06-02-2010 at 04:13 PM.

#32

TECH Junkie

iTrader: (17)

also saw this in another thread

Here is another thing to check which is very important.

When ussing the same slave but changing the bearing --make sure you remove ALL of the old bearing.Ussually there is a spacer of sorts that will be left behind from the old bearing -inside the slave.Just need a small screwdriver to fish it out.If left in there it is almost 1/8" spacer.

When ussing the same slave but changing the bearing --make sure you remove ALL of the old bearing.Ussually there is a spacer of sorts that will be left behind from the old bearing -inside the slave.Just need a small screwdriver to fish it out.If left in there it is almost 1/8" spacer.

#33

ive had 3 specs and if memory serves that is what one of my old shims looked like, kinda a compressed paper material. the later shims i got were metal. its not a seal

although im not sure thats your problem, its a place to start

although based on your no shim measurements i think there may be an issue with the clutch if your sure the slave is fully compressed when your measuring. maybe loosen the bleeder to make it easier to fully compress

shitty

although im not sure thats your problem, its a place to start

although based on your no shim measurements i think there may be an issue with the clutch if your sure the slave is fully compressed when your measuring. maybe loosen the bleeder to make it easier to fully compress

shitty

Textralia just emailed me saying he would call so we will see

#34

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

That little shim would not keep the clutch from holding. You have a bigger issue. I was hoping to see a spacer much larger than that. Its really hard to say without being hands on and seeing everything for myself. When I installed my twin disk I had to measure everything. It was made for a C6 Z06 and I had to have a .950" spacer. Luckily, the LS7 slave is about .950" longer than my stock slave is so that made that really easy. I wish I could say yes its this or that but like I said, its hard to troubleshoot over a keyboard. Keep us posted as to what Tex has to say about it.

#35

LS1TECH & Trucks Sponsor

iTrader: (34)

That is gasket material which is very commonly used as a shim, it should not be there and will definitely cause engagement issues. I can't guarantee that is your only problem, but it is a problem, especially on a twin where the engagement/disengagement values are cut in half (split between two disks)

__________________

800-456-0211 / PM / Facebook

WHIPPLE Superchargers, Procharger, Magnuson, Powerbond Sale, HPTuners packages!, Trickflow, AFR, PRC, CHE Trunion upgrade, $100 7.400" pushrod set, Custom Cam of your choice

800-456-0211 / PM / Facebook

WHIPPLE Superchargers, Procharger, Magnuson, Powerbond Sale, HPTuners packages!, Trickflow, AFR, PRC, CHE Trunion upgrade, $100 7.400" pushrod set, Custom Cam of your choice

#36

RedHatRdRacer is a horrible seller and has committed internet fraud and wont answer my messages or refund my money. I am submitting all this evidence to my bank tomorrow and I was told they will reverse the funds. I can get Jarrod from textralia to send me a letter stating what the correct measurements should be for the clutch and I can take pictures of the clutch using my caliper to prove everything is off!

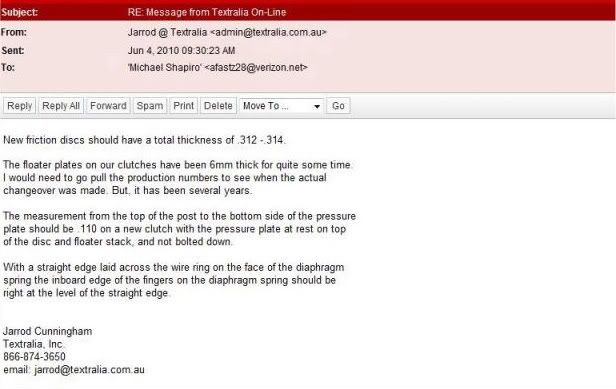

I was on the phone with Jarrod from Textralia yesterday and we took caliper measurements of the entire clutch. The clutch is back from 2007 or later, it has a 10mm thick floater disk (old style). With the clutch assembled but not bolted down it should have 110 thousandths between the top of the post on the flywheel and the bottom of the pressure plate. It has about half of that! So basically Jarrod says the clutch is not right and would require a re-build with heavy machining/milling to get it to work. Also when the pressure plate is bolted down the fingers of the spring are supposed to be completely flat and you can tell in the pics that they are not. The pads however do measure close to what they should be new though so he has no idea what previous seller did (I think he has tried to rebuild clutch a few times).

I painted the clutch with 2000 deg paint because of a bunch of surface rust on flywheel but did not get any on friction surfaces (I am going to remove paint this weekend to prepare clutch to be returned to seller)

Something major is wrong with the clutch and I was told it was like new with 100 miles. Turns out seller installed clutch wrong (disks not lined up for even load), had engagement problems, and then sold it to me saying it was basically new. He is digging in his heals and doubt he will do the right thing and take his busted clutch back. I am going to have to take legal action. There was no shim installed behind slave on my car and clutch barely moved around on my driveway (it moved but did not grab hard at all…..about 10% as much grab as my textralia single disk )

Sellers picture of clutch installed wrong (disks not lined up): (causes uneven load) You can also see the surface rust on the clutch that was supposed to have 100 miles on it .

Seller had problems with engagement :

Where seller stated Condition:

btw I will do the 900 shipped Do you have pics of the clutch? I do not have pictures. I ran it for about 100 miles give or take a little then started parting out the car to go back to stock

I installed clutch using instructions from textralia. Disks are lined up properly and in correct order/the right direction. I used stock flywheel bolts and used red locktite on pressure plate bolts which I put at 60 ft lbs. I have an OEM slave and Tick master cylinder. If I put car in gear with e-brake on, I can still turn motor over with breaker bar because the clutch just doesn’t hold.

Instructions from textralia:

Here is it on my car from 2 days ago: (Clutch disks are lined up for even load)

Also the fingers on the pressure plate springs are supposed to be flat when clutch is torqued down. You can obviously see that they are not.

I was on the phone with Jarrod from Textralia yesterday and we took caliper measurements of the entire clutch. The clutch is back from 2007 or later, it has a 10mm thick floater disk (old style). With the clutch assembled but not bolted down it should have 110 thousandths between the top of the post on the flywheel and the bottom of the pressure plate. It has about half of that! So basically Jarrod says the clutch is not right and would require a re-build with heavy machining/milling to get it to work. Also when the pressure plate is bolted down the fingers of the spring are supposed to be completely flat and you can tell in the pics that they are not. The pads however do measure close to what they should be new though so he has no idea what previous seller did (I think he has tried to rebuild clutch a few times).

I painted the clutch with 2000 deg paint because of a bunch of surface rust on flywheel but did not get any on friction surfaces (I am going to remove paint this weekend to prepare clutch to be returned to seller)

Something major is wrong with the clutch and I was told it was like new with 100 miles. Turns out seller installed clutch wrong (disks not lined up for even load), had engagement problems, and then sold it to me saying it was basically new. He is digging in his heals and doubt he will do the right thing and take his busted clutch back. I am going to have to take legal action. There was no shim installed behind slave on my car and clutch barely moved around on my driveway (it moved but did not grab hard at all…..about 10% as much grab as my textralia single disk )

Sellers picture of clutch installed wrong (disks not lined up): (causes uneven load) You can also see the surface rust on the clutch that was supposed to have 100 miles on it .

Seller had problems with engagement :

I have a healthy 42x cid Iron motor, with a face-plated t56 I recently went from the SPEC 4 to a Textralia dual disk. I have the shimmed slave cylinder which is new (the plate SPEC provides with there clutch kits to make sure the slave is flush) I have a stock GM Master cylinder and the McCloud line....

When I crank the car I can put it in gear fine.... but i can leave it in gear and let off the clutch and even get out of the car (not literally) and the car WONT move...

I have bleed and bleed and bled the Slave... there is no air in it... I have ran 20oz of fluid threw it easily....

Would like to hear some ideas on whats up, WOULD LOVE to have this running by friday....

thanks in advance

Bryan

When I crank the car I can put it in gear fine.... but i can leave it in gear and let off the clutch and even get out of the car (not literally) and the car WONT move...

I have bleed and bleed and bled the Slave... there is no air in it... I have ran 20oz of fluid threw it easily....

Would like to hear some ideas on whats up, WOULD LOVE to have this running by friday....

thanks in advance

Bryan

Originally Posted by RedHatRdRacer

Originally Posted by AFASTYZFR1

Originally Posted by RedHatRdRacer

Originally Posted by AFASTYZFR1

Is your Textralia Twin Disk new? They are only $1250 shipped straight from Textralia. I would be able to possibly do $900 shipped, just thought I would ask.

Thanks,

Michael

Thanks,

Michael

btw I will do the 900 shipped

I installed clutch using instructions from textralia. Disks are lined up properly and in correct order/the right direction. I used stock flywheel bolts and used red locktite on pressure plate bolts which I put at 60 ft lbs. I have an OEM slave and Tick master cylinder. If I put car in gear with e-brake on, I can still turn motor over with breaker bar because the clutch just doesn’t hold.

Instructions from textralia:

Place loctite in the bolt holes, not on the bolt as it tends to get wiped off when installing the bolt through the pressure plate hat.

Torque the bolts to 55 lbs (stock GM spec).

The pressure plate is neutrally balanced, so orientation isn't an issue if you move it. But, try to keep it the way we sent it if you can, and the hat is usally set up "best" the way we send it.

Line the discs up so the plates are in line with one another, and the pucks aren't off a few splines. This allows for consistent loading on the clutch.

I am including pictures to ensure you re-assemble in the right order. They are numbered 1-2-3-4. The clutch discs should be marked also.

Torque the bolts to 55 lbs (stock GM spec).

The pressure plate is neutrally balanced, so orientation isn't an issue if you move it. But, try to keep it the way we sent it if you can, and the hat is usally set up "best" the way we send it.

Line the discs up so the plates are in line with one another, and the pucks aren't off a few splines. This allows for consistent loading on the clutch.

I am including pictures to ensure you re-assemble in the right order. They are numbered 1-2-3-4. The clutch discs should be marked also.

Here is it on my car from 2 days ago: (Clutch disks are lined up for even load)

Also the fingers on the pressure plate springs are supposed to be flat when clutch is torqued down. You can obviously see that they are not.

#38

I don't think I will have a problem, it will just be a matter of faxing in the evidence and forms to my bank.

Thanks for trying to help me, I tried everything under the sun to get the thing to work and when I finally get on the phone with textralia he said the floater plate and dowels that come off the flywheel need to me milled down almost 60 thousandths.

Oh, and another thing wrong with clutch is the rivets on the flywheel side of the disk closest to the flywheel were damaged.....I will get pics of that this morning.

Thanks for trying to help me, I tried everything under the sun to get the thing to work and when I finally get on the phone with textralia he said the floater plate and dowels that come off the flywheel need to me milled down almost 60 thousandths.

Oh, and another thing wrong with clutch is the rivets on the flywheel side of the disk closest to the flywheel were damaged.....I will get pics of that this morning.

#39

With clutch tightened down clutch fingers should be flat and they are not

Measuring clearance between dowels and pressure plate with it just sitting there not bolted down. Jarrod from textralia says new one measures 110 thousands of an inch, this clutch reads 56 thousandths....Thats HALF of what it should be......no wonder the clutch wont hold.

Here are damaged rivets (on flywheel side of disc closest to flywheel)

Measuring clearance between dowels and pressure plate with it just sitting there not bolted down. Jarrod from textralia says new one measures 110 thousands of an inch, this clutch reads 56 thousandths....Thats HALF of what it should be......no wonder the clutch wont hold.

Here are damaged rivets (on flywheel side of disc closest to flywheel)