Rod bolt install write-up

#1

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

I figured since I couldn't find a write-up with pictures, that I'd take it up for anyone that is looking to do this in the future. Disclaimer: I am not responsible for any damage done to your car, use this write-up at your own discretion. Ok, on to the write-up.

First thing you want to do is get your car up on jack stands and remove the front wheels and drain your oil. Be sure you disconnect your battery and choke the rear wheels, safety first!

Youíll need to remove your serpentine belt in order to turn the crank over later in the install. The A/C belt can stay.

Next, loosen the bolts (13mm & 15mm) holding the front shocks to the lower A-arms and also loosen the end links holding the sway bar.

Youíll also need to loosen the bolt holding the spindle to the upper A-arm (15mm nut). Sorry, no pic of that. Be sure to support the lower A-arm so that the brake line isnít ruptured. I used a zip-tie and some rope to tie the brake caliper to the spring. This kept the lower A-arm assembly from dropping too much and put no stress on the brake line.

Next up is loosening the motor mounts. It helps to jack the engine up just a little bit to remove tension on the bolts so they can be a little easier to get out. First, loosen the nut holding the transmission mount to the transmission cross-member. It should be an 18mm nut if youíre using the stock unit. This will allow you to raise the engine/transmission a bit. Youíll have to jack the engine up, I used a piece of 2x4 and placed my jack where the transmission bolts on to the bellhousing. Now itís time to move to the motor mounts. Here is a pic of the driverís side motor mount.

Use an 18mm socket or wrench to loosen the nut. The bolt itself will eventually start to spin so youíll have to hold it using another wrench/ratchet. Guess what though? The alternator is in the way! You guessed it, youíll have to unbolt the alternator from the block. Doing this isnít terribly difficult. Youíll need to unbolt the 3 15mm bolts on the front side of the alternator, and a 13mm bolt thatís hiding on the backside. Just feel around for it and youíll find it. Once the four bolts are loosened, just set aside the alternator so it wonít bother you. I didnít fully remove it, I simply worked around it and didnít have any trouble. With the alternator out of the way, now you can remove the bolt holding the driverís side motor mount to the K-member.

First thing you want to do is get your car up on jack stands and remove the front wheels and drain your oil. Be sure you disconnect your battery and choke the rear wheels, safety first!

Youíll need to remove your serpentine belt in order to turn the crank over later in the install. The A/C belt can stay.

Next, loosen the bolts (13mm & 15mm) holding the front shocks to the lower A-arms and also loosen the end links holding the sway bar.

Youíll also need to loosen the bolt holding the spindle to the upper A-arm (15mm nut). Sorry, no pic of that. Be sure to support the lower A-arm so that the brake line isnít ruptured. I used a zip-tie and some rope to tie the brake caliper to the spring. This kept the lower A-arm assembly from dropping too much and put no stress on the brake line.

Next up is loosening the motor mounts. It helps to jack the engine up just a little bit to remove tension on the bolts so they can be a little easier to get out. First, loosen the nut holding the transmission mount to the transmission cross-member. It should be an 18mm nut if youíre using the stock unit. This will allow you to raise the engine/transmission a bit. Youíll have to jack the engine up, I used a piece of 2x4 and placed my jack where the transmission bolts on to the bellhousing. Now itís time to move to the motor mounts. Here is a pic of the driverís side motor mount.

Use an 18mm socket or wrench to loosen the nut. The bolt itself will eventually start to spin so youíll have to hold it using another wrench/ratchet. Guess what though? The alternator is in the way! You guessed it, youíll have to unbolt the alternator from the block. Doing this isnít terribly difficult. Youíll need to unbolt the 3 15mm bolts on the front side of the alternator, and a 13mm bolt thatís hiding on the backside. Just feel around for it and youíll find it. Once the four bolts are loosened, just set aside the alternator so it wonít bother you. I didnít fully remove it, I simply worked around it and didnít have any trouble. With the alternator out of the way, now you can remove the bolt holding the driverís side motor mount to the K-member.

#2

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Now you can move onto the passenger motor mount. Before you can even see the motor mount, you must drop the starter. Itís held on to the block by two 13mm bolts, then two wires connected to it (8mm & 13mm). Remove the two 13mm bolts and the two wires running to the starter, along with the dust cover thatís located on the front side of the bellhousing (10mm bolt). Here are a couple of pics of the starter and the bolts holding it to the block.

I had some trouble with this side, in order to remove the bolt running through the center of the mount, you have to remove the A/C compressor, then youíd have to deal with recharging the system once youíre done. I decided not to mess with that, so I unbolted the motor mount from the block itself. Hereís a pic of the motor mount.

I decided not to mess with that, so I unbolted the motor mount from the block itself. Hereís a pic of the motor mount.

Looks pretty messy, huh? To get a better view, and move some clutter out of the way, I unbolted the ground that is running to the block (15mm bolt).

Move the wires out of the way and enjoy the clear view of the motor mount.

Now it looks easier to remove the 4 13mm bolts holding the motor mount clam shell to the block (noticed I said LOOKS easier). A swivel joint will help out a good bit here and save you from cursing the heavens.

Once you have all 4 bolts removed, we can move onto unbolting the steering linkage. This isnít as hard as I thought it would be, I just loosened one 11mm bolt which you can reach from the engine bay with a long extension.

I had some trouble with this side, in order to remove the bolt running through the center of the mount, you have to remove the A/C compressor, then youíd have to deal with recharging the system once youíre done.

I decided not to mess with that, so I unbolted the motor mount from the block itself. Hereís a pic of the motor mount.

I decided not to mess with that, so I unbolted the motor mount from the block itself. Hereís a pic of the motor mount.

Looks pretty messy, huh? To get a better view, and move some clutter out of the way, I unbolted the ground that is running to the block (15mm bolt).

Move the wires out of the way and enjoy the clear view of the motor mount.

Now it looks easier to remove the 4 13mm bolts holding the motor mount clam shell to the block (noticed I said LOOKS easier). A swivel joint will help out a good bit here and save you from cursing the heavens.

Once you have all 4 bolts removed, we can move onto unbolting the steering linkage. This isnít as hard as I thought it would be, I just loosened one 11mm bolt which you can reach from the engine bay with a long extension.

#3

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Ok, now that youíve loosened both motor mounts, the steering linkage, the socks, spindles and sway bar, we can move onto lowering the K-member.

This is basically what I wanted to know when looking around for a write-up, where to unbolt the K-member from the frame. Well, here it is. There are a total of 6 bolts holding the K-member to the frame of your f-body (all 18mm). Here are a couple of pics showing the three driverís side bolts.

Before you go and loosen these bolts, be sure your K-member is supported by a jack or two. Youíll need to break out your breaker bar and use a little muscle to break these bolts loose, so put some back into it. With these bolts out of the way, the K-member should drop. I had to give it some encouraging whacks with a rubber mallet in order for mine to drop, but it got there. I decided not to completely drop it.

With the K-member lowered, we can now move onto the oil pan bolts. There are about 13 10mm bolts holding the pan to the block and two 15mm bolts holding the pan to the bellhousing. Loosen and remove all of these bolts and your oil pan should drop out the back. Youíll need to maneuver it to get it out all the way and maybe adjust the height of the K-member/engine, but it will come out. Once you have the pan off, youíll have a clear view of the pick up tube and the crank oil deflector pictured below.

This is basically what I wanted to know when looking around for a write-up, where to unbolt the K-member from the frame. Well, here it is. There are a total of 6 bolts holding the K-member to the frame of your f-body (all 18mm). Here are a couple of pics showing the three driverís side bolts.

Before you go and loosen these bolts, be sure your K-member is supported by a jack or two. Youíll need to break out your breaker bar and use a little muscle to break these bolts loose, so put some back into it. With these bolts out of the way, the K-member should drop. I had to give it some encouraging whacks with a rubber mallet in order for mine to drop, but it got there. I decided not to completely drop it.

With the K-member lowered, we can now move onto the oil pan bolts. There are about 13 10mm bolts holding the pan to the block and two 15mm bolts holding the pan to the bellhousing. Loosen and remove all of these bolts and your oil pan should drop out the back. Youíll need to maneuver it to get it out all the way and maybe adjust the height of the K-member/engine, but it will come out. Once you have the pan off, youíll have a clear view of the pick up tube and the crank oil deflector pictured below.

#4

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

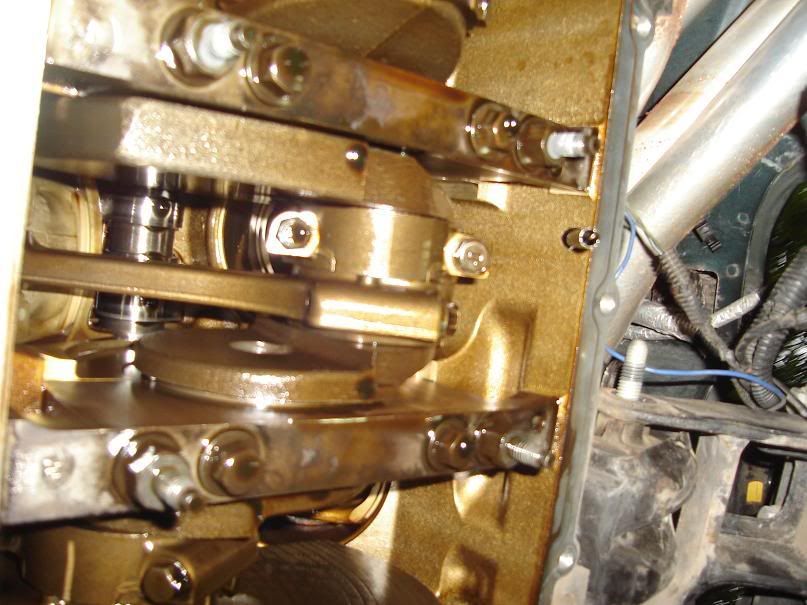

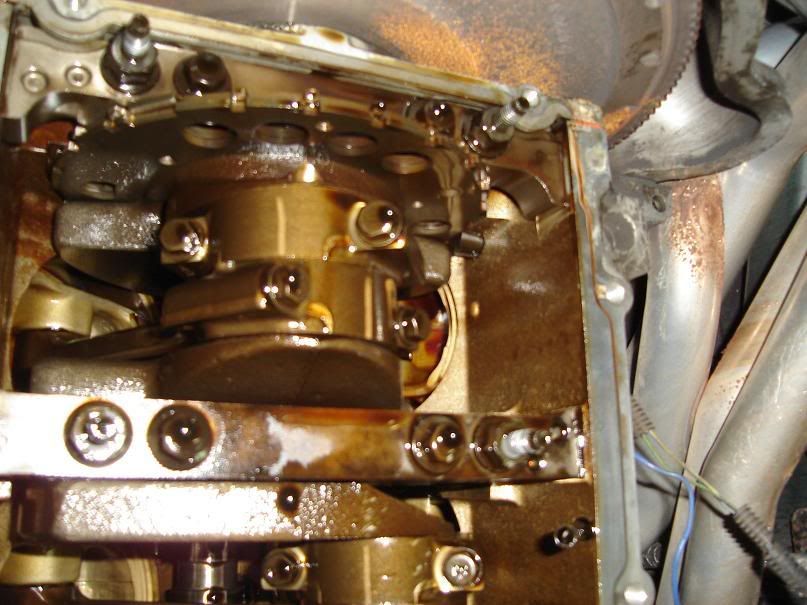

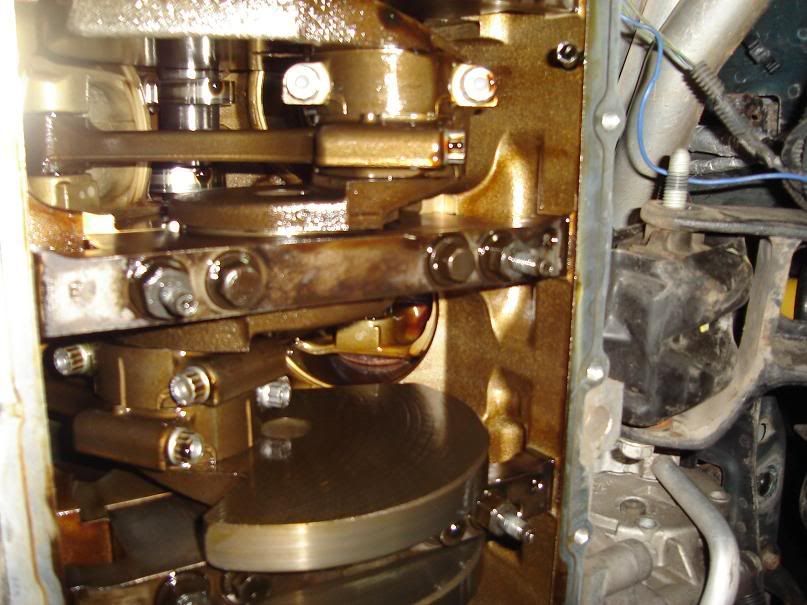

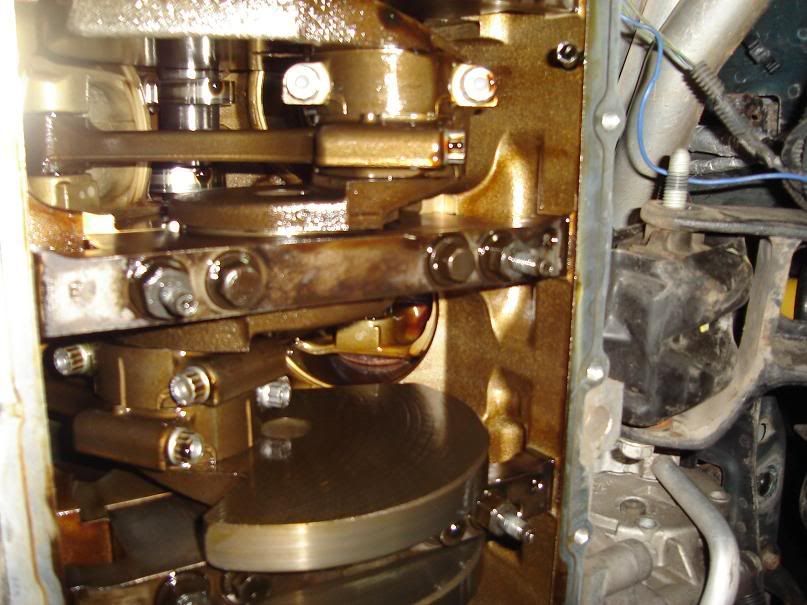

To remove this, you have to unbolt the pickup tube from the oil pump (10mm bolt) and unbolt the 13mm nut holding the pickup tube to the crank oil deflector. With the pickup tube out of the way, you can unbolt the remaining 7 13mm nuts holding the crank oil deflector. Remove the deflector plate and marvel at the rotating assembly of your LS1.

Now, we can finally swap out the rod bolts! Depending on what bolts you decided to use, the instructions will vary. Use the directions supplied by the bolt company. I went with Katech bolts, so it was pretty straightforward.

I removed one bolt at a time from each rod cap (did two at a time). In other words, make sure there is one bolt tightened on each rod cap at all times! Failing to do so will result in messing up your bearings. In some year LS1ís, there are ferrules in the bolt holes, which you absolutely must remove, otherwise you risk damage to your engine. For some reason, my engine did not come with these ferrules, so I simply removed the bolt and replaced it with a new one.

After removing the bolts, I lubed up the new Katech bolt threads and head with the assembly lube and torqued it down. I torqued the bolt down 3 times, twice at 30 lb/ft, then a final pass at 50 lb/ft. Youíll have to turn the crank over in order to reach some bolts, so just use a 24mm socket and a breaker bar to rotate it by hand accordingly.

Now, we can finally swap out the rod bolts! Depending on what bolts you decided to use, the instructions will vary. Use the directions supplied by the bolt company. I went with Katech bolts, so it was pretty straightforward.

I removed one bolt at a time from each rod cap (did two at a time). In other words, make sure there is one bolt tightened on each rod cap at all times! Failing to do so will result in messing up your bearings. In some year LS1ís, there are ferrules in the bolt holes, which you absolutely must remove, otherwise you risk damage to your engine. For some reason, my engine did not come with these ferrules, so I simply removed the bolt and replaced it with a new one.

After removing the bolts, I lubed up the new Katech bolt threads and head with the assembly lube and torqued it down. I torqued the bolt down 3 times, twice at 30 lb/ft, then a final pass at 50 lb/ft. Youíll have to turn the crank over in order to reach some bolts, so just use a 24mm socket and a breaker bar to rotate it by hand accordingly.

#5

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

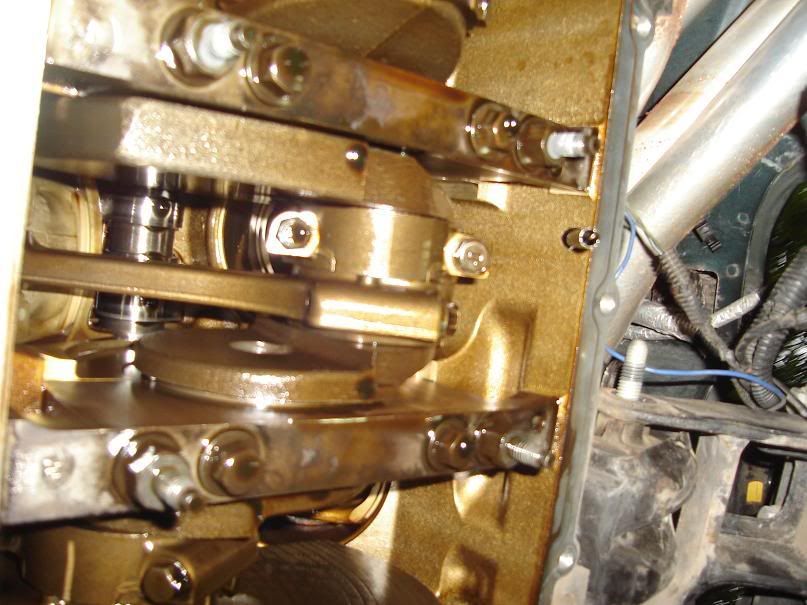

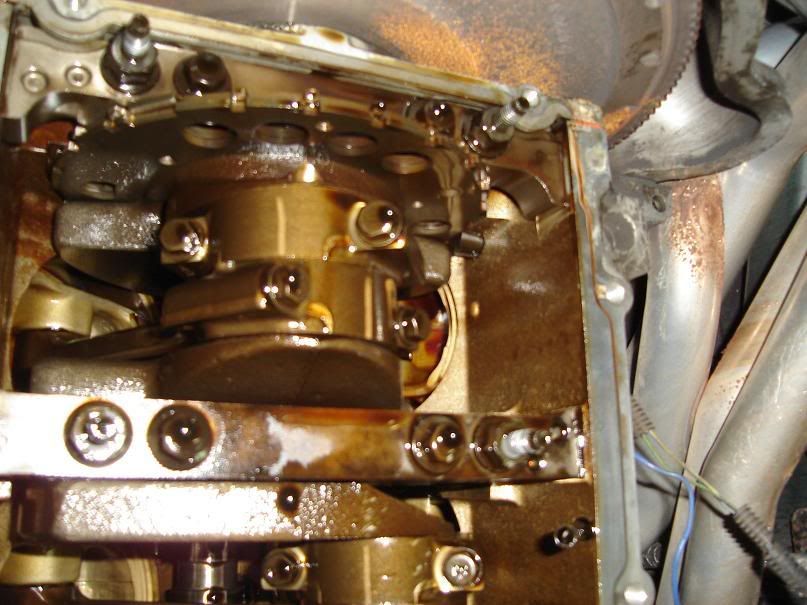

Hereís a pic of the finished product. Isnít it beautiful?

Once youíre done swapping out all the rod bolts, itís time to put everything back together. Bolt the oil deflector plate on and torque the 8 bolts down to 18 lb/ft. Donít forget the oil pickup tube! Be sure to put the oil pump O-ring on the pickup tube, which is a piece of cake doing it this way. With both of these back on, itís time to bolt down the oil pan. First hand thread all bolts into the block, then torque the two 15mm bolts down to 35 lb/ft. Your pan should be aligned now, just torque down the remaining 10mm bolts. The rest is basically assembled in the reverse order of the tear down. Congratulations, youíve completed a connecting rod bolt swap! Now you can spin your LS1 to the moon and be worry free! Well, maybe not to the moon, but you get the ideaÖ

Well, maybe not to the moon, but you get the ideaÖ

Once youíre done swapping out all the rod bolts, itís time to put everything back together. Bolt the oil deflector plate on and torque the 8 bolts down to 18 lb/ft. Donít forget the oil pickup tube! Be sure to put the oil pump O-ring on the pickup tube, which is a piece of cake doing it this way. With both of these back on, itís time to bolt down the oil pan. First hand thread all bolts into the block, then torque the two 15mm bolts down to 35 lb/ft. Your pan should be aligned now, just torque down the remaining 10mm bolts. The rest is basically assembled in the reverse order of the tear down. Congratulations, youíve completed a connecting rod bolt swap! Now you can spin your LS1 to the moon and be worry free!

Well, maybe not to the moon, but you get the ideaÖ

Well, maybe not to the moon, but you get the ideaÖ

Trending Topics

#8

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by brad8266

You do not need to remove the AC compressor lines, just unbolt the compressor from the bracket and sit it on the swaybar. That way you can just take out the 18mm bolt in the motor mount.

Now it should be finished.

Now it should be finished.

#11

TECH Senior Member

iTrader: (23)

Join Date: Aug 2005

Location: Watertown, NY

Posts: 8,797

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Krab

Dammit, you beat me to posting the last two posts.  Now it should be finished.

Now it should be finished.

Now it should be finished.

Now it should be finished.

You do not need to remove the AC compressor lines, just unbolt the compressor from the bracket and tie it up somewhere. That way you can just take out the 18mm bolt in the motor mount. No need to undo the mount from the block.

#13

TECH Senior Member

iTrader: (23)

Join Date: Aug 2005

Location: Watertown, NY

Posts: 8,797

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by connexion2005

bad *** man...im considering rod bolts during my cam setup due to the weaker bolts on the 98's ive heard about...what exactly goes wrong with them when spun to high?

#16

TECH Addict

Thread Starter

iTrader: (28)

Join Date: Sep 2002

Location: Central Texas

Posts: 2,170

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by john563

great write up and pics.How long did it take you start to finish?

thanks

john

thanks

john

brad8266: Good to know you don't have to completely remove the compressor, I'm sure that will come in handy for people who do this in the future.

Thanks for the props guys, it wasn't really easy doing this install by myself.

#19

TECH Fanatic

iTrader: (17)

Join Date: Sep 2006

Location: dayton ohio

Posts: 1,638

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Krab

From start to finish, it took me about 16 hours. Started it yesterday morning and finished today after lunch. Lowering the K-member gave me a hard time because I couldn't figure out what was holding the driver's side up. It ended up being the steering linkage.

brad8266: Good to know you don't have to completely remove the compressor, I'm sure that will come in handy for people who do this in the future.

Thanks for the props guys, it wasn't really easy doing this install by myself.

brad8266: Good to know you don't have to completely remove the compressor, I'm sure that will come in handy for people who do this in the future.

Thanks for the props guys, it wasn't really easy doing this install by myself.