Aeroquip socketless hose (FC598) - anyone else with issues?

#1

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I found a fuel leak from one of my -6an Aeroquip hoses, under pressure it was shooting a hairline stream of fuel onto my exhaust pipe.

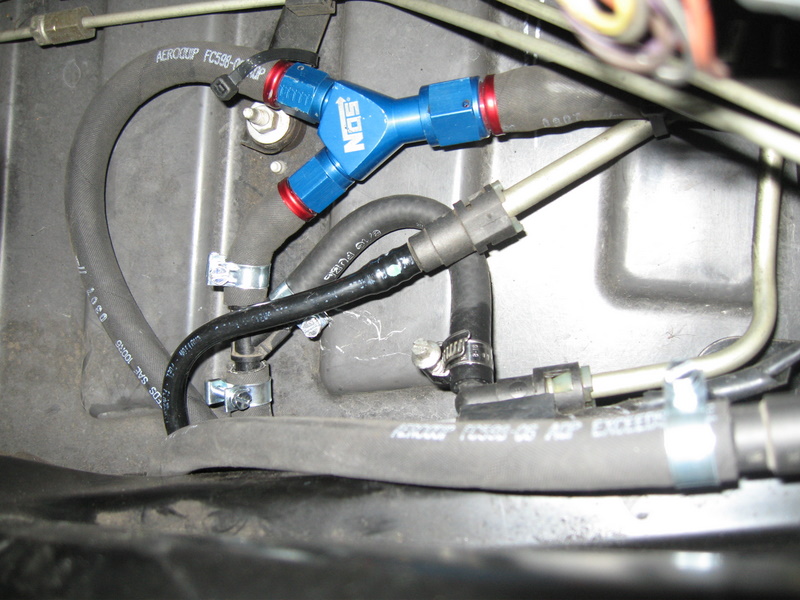

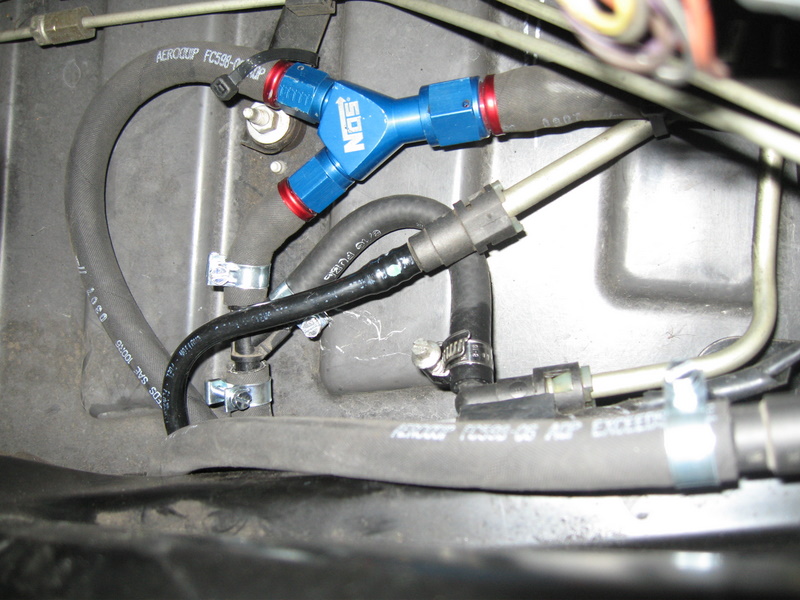

In the pic below, it was the short hose off the bottom of the NOS 'Y'-connector. I removed it, cut it open and found there was a section of the inner hose that was burst. The inner hose pulled apart like old pasta, no effort was needed to tear pieces of inner hose apart. The hose is slightly curved in the pic, the burst area was on the inside area of the curve next to the end of the fitting inside the hose. The spray leak appeared on the outside curve of the hose.

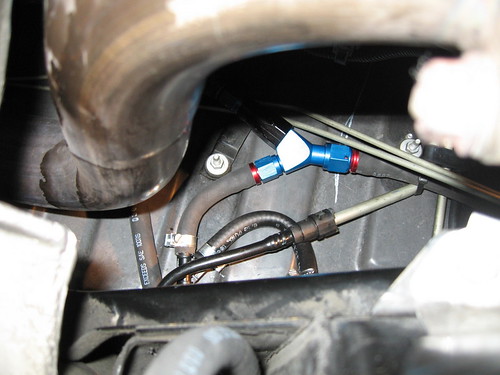

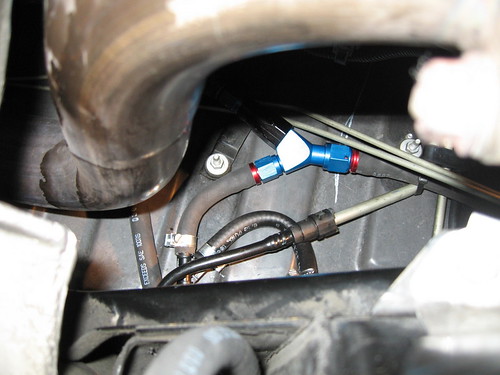

This was above the transmission in the rear of the C5, where the stock fuel filter used to be but a bit further away from the exhaust pipes than the stock fuel filter. Since this is near the over the axle exhaust pipes, I suspect heat has something to do with softening the inner liner. Has anyone else experienced degraded Aeroquip hoses? I'm worried now, I'm wondering if there are fake hoses in the market and if I have to replace all these new -6an and -8an hoses.

In the pic below, it was the short hose off the bottom of the NOS 'Y'-connector. I removed it, cut it open and found there was a section of the inner hose that was burst. The inner hose pulled apart like old pasta, no effort was needed to tear pieces of inner hose apart. The hose is slightly curved in the pic, the burst area was on the inside area of the curve next to the end of the fitting inside the hose. The spray leak appeared on the outside curve of the hose.

This was above the transmission in the rear of the C5, where the stock fuel filter used to be but a bit further away from the exhaust pipes than the stock fuel filter. Since this is near the over the axle exhaust pipes, I suspect heat has something to do with softening the inner liner. Has anyone else experienced degraded Aeroquip hoses? I'm worried now, I'm wondering if there are fake hoses in the market and if I have to replace all these new -6an and -8an hoses.

#3

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I changed the location of the fuel pressure sender since it was an eyesore. While removing it I nicked an -8an hose near the rail fitting. Stupid me after the above experience, trimmed the hose a bit shorter and thought the hose behaved oddly (the layers were not 'as one' as when it was new, and inner lining is super soft), and pressed it on as usual (I made all the other connections which are fine). Now it's leaking bad, I'll have to wait till I have time to fix that mess. Maybe only new hoses can be pressed onto fittings.

#5

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Put the fitting on the ground (on wood), put the hose on the end, grab with both hands, and put my weight on my hands (and sometimes my knees on my hands for the -8an).

The 90deg fittings are a P.I.T.A., so I put the vise on the ground, close it enough to support the barbed end, then put my weight on the hose.

The 90deg fittings are a P.I.T.A., so I put the vise on the ground, close it enough to support the barbed end, then put my weight on the hose.

#6

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I'm reading through this Eaton/Aeroquip document (http://hydraulics.eaton.com/products...Q-MC001-E1.pdf). Page 3 says max temperature for petrolum based fuels is 200deg F. I'm thinking engine bays and the underbody gets hotter than that.

Hose label says 'AEROQUIP FC598-06 AQP EXCEEDS SAE 100R6'.

This is where I'm using it:

The stains on the exhaust pipe are from gasoline spraying on it (left side of pic). This pic was taken after I replaced the hose.

Hose label says 'AEROQUIP FC598-06 AQP EXCEEDS SAE 100R6'.

This is where I'm using it:

The stains on the exhaust pipe are from gasoline spraying on it (left side of pic). This pic was taken after I replaced the hose.

Last edited by blu00rdstr; 06-12-2008 at 03:27 PM.

Trending Topics

#10

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I wanted to call Eaton/Aeroquip, but their site refers you to their distributors. I bought the hoses from JEGS and Vic Hubbard both who advertise these hoses under the fuel hoses and connectors category, so I called JEGS and talked to them about it.

I told JEGS I was concerned about the 200degree fuel rating of the hoses. The JEGS tech read off some specs for the hoses, and said they'd work fine. I told him I had concerns about leaks that sprang in hot areas, and that one of the hoses leaked a stream of gasoline onto the exhaust pipes, he suggested if I ran into problems to use steel braided hose in high heat areas. After the call I looked up the fuel temperature rating of braided hose, and they're also 200degrees.

Not many places to raise the potentially lethal topic, but I'll keep a good sized fire extinguisher in the car now. I think using hoses rated for 200degrees fuel in an automotive application is a huge exposure.

Maybe I should call Vic Hubbard.

I told JEGS I was concerned about the 200degree fuel rating of the hoses. The JEGS tech read off some specs for the hoses, and said they'd work fine. I told him I had concerns about leaks that sprang in hot areas, and that one of the hoses leaked a stream of gasoline onto the exhaust pipes, he suggested if I ran into problems to use steel braided hose in high heat areas. After the call I looked up the fuel temperature rating of braided hose, and they're also 200degrees.

Not many places to raise the potentially lethal topic, but I'll keep a good sized fire extinguisher in the car now. I think using hoses rated for 200degrees fuel in an automotive application is a huge exposure.

Maybe I should call Vic Hubbard.

#13

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

What I don't understand, is why the aftermarket hoses (Socketless, Braided hose) are advertised as automotive fuel hose and is only rated to 200degrees for petroleum fuel. The underbody failure I experienced was further from exhaust than the original stock fuel filter was.

The car had a few miles on it and a good set of dyno sessions before the hoses started leaking. They were dry and tight when they were installed.

I do plan on adding some Thermo Tec heat sheild wraps on the hoses. Both of the local speed shops in the bay area (Vic Hubbard, Goodies) carry them.

- How can factory lines be fine in an area where aftermarket hoses demonstrate how dangerous they can be?

- How can vendors advertise these as automotive fuel hoses, if engine bays are hotter than the hose rating?

The car had a few miles on it and a good set of dyno sessions before the hoses started leaking. They were dry and tight when they were installed.

I do plan on adding some Thermo Tec heat sheild wraps on the hoses. Both of the local speed shops in the bay area (Vic Hubbard, Goodies) carry them.

#14

10 Second Club

iTrader: (5)

Join Date: Nov 2001

Location: Cali/Bay Area

Posts: 3,412

Likes: 0

Received 0 Likes

on

0 Posts

I know ALOT of folks using this hose with no issues including turbo apps where the temps get warm in the engine bay. Not sure what happend on yours, but is strange, maybe a bad batch. Any possibility that it got kinked when installing it or anything? The tear in the inner hose, is it right at the end of the barbed connector?

I just bought a bunch of -8, -10 and -12 AN AQP socketless hose too. All mine say good to 300 degrees and 250 psi.

Edit: Just read threw that Doc you posted and see it's rated at different temps depending on what fluid is being used in the hose, gas being 200 deg.

I just bought a bunch of -8, -10 and -12 AN AQP socketless hose too. All mine say good to 300 degrees and 250 psi.

Edit: Just read threw that Doc you posted and see it's rated at different temps depending on what fluid is being used in the hose, gas being 200 deg.

Last edited by DanZ28; 06-14-2008 at 03:58 AM.

#15

TECH Senior Member

iTrader: (3)

"Any possibility that it got kinked when installing it or anything? The tear in the inner hose, is it right at the end of the barbed connector?"

My thots exactly. There are specs that spell out the minimum bend radius, for hoses. Maybe the cuts are caused by the hose being pulled into a radius, that's too small???

I've used the Pushlok stuff since it first came out... NEVER had any such failures.

My thots exactly. There are specs that spell out the minimum bend radius, for hoses. Maybe the cuts are caused by the hose being pulled into a radius, that's too small???

I've used the Pushlok stuff since it first came out... NEVER had any such failures.

#16

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

The pic in post #1 shows the radius which isn't much of a bend. The pic in post #7 shows where the inner liner burst which is close to the fitting, but it wasn't cut by the fitting. So that's my first data point.

My second data point is how easily the inner liner pulls apart, there's very little resistance at all to pulling it apart. It's like old wet pasta or wet cardboard.

My third data point is the hose temperature rating for fuel of 200degrees max, which much lower than what vendors are advertising when they sell this a 'fuel hose'.

Since both failure locations were near heat, based on the data points my conclusion is that the hose is even more delicate in high heat areas, and is inappropriate for use in engine compartments and underbody areas. This means the hose should not be advertised as fuel hose for automotive applications, since fuel hose is used in both engine compartments and underbody.

My first experience (the first data point) is my entire experience, so I've seen failures on 100% of the implementations.

I wish I could notify or escalate this to Eaton for the correction or resolution but I don't have the contacts. Their website refers technical questions to distributors, and the contacts at the distributors appear to be insufficiently trained on the products.

The alternatives are braided hose (seeps fuel, same temperature ratings) or to add heat sheilds (hose blankets) to hot areas. For now I'm going to add heat shield blankets in an attempt to keep hose temps down below 200degrees.

My second data point is how easily the inner liner pulls apart, there's very little resistance at all to pulling it apart. It's like old wet pasta or wet cardboard.

My third data point is the hose temperature rating for fuel of 200degrees max, which much lower than what vendors are advertising when they sell this a 'fuel hose'.

Since both failure locations were near heat, based on the data points my conclusion is that the hose is even more delicate in high heat areas, and is inappropriate for use in engine compartments and underbody areas. This means the hose should not be advertised as fuel hose for automotive applications, since fuel hose is used in both engine compartments and underbody.

My first experience (the first data point) is my entire experience, so I've seen failures on 100% of the implementations.

I wish I could notify or escalate this to Eaton for the correction or resolution but I don't have the contacts. Their website refers technical questions to distributors, and the contacts at the distributors appear to be insufficiently trained on the products.

The alternatives are braided hose (seeps fuel, same temperature ratings) or to add heat sheilds (hose blankets) to hot areas. For now I'm going to add heat shield blankets in an attempt to keep hose temps down below 200degrees.

Last edited by blu00rdstr; 06-14-2008 at 04:07 PM.

#17

9 Second Club

I'd say its probably a fitting issue.

I use Earls throughout, and have no problems whatsoever. The fact more than one of yours is damaged, would point more likely to an installation problem, if they were all installed the same way.

I clamp a -6 fitting into the vice ( or the relevant size ), then screw my hose end onto that, so the hose end is totally secure.. I heat the hose with a heat gun a little to make it softer, lubricate inside the hose with oil, and the barb itself, and it takes a reasonable push to engage the hose over the full barb. Then leave to cool normally.

You seem to mention you just shove the hose on with your weight. If so, its highly likely the hose is catching internally, and getting damaged. The push fit stuff is a very tight fit for a reason......so lubrication is required when installing.

I use Earls throughout, and have no problems whatsoever. The fact more than one of yours is damaged, would point more likely to an installation problem, if they were all installed the same way.

I clamp a -6 fitting into the vice ( or the relevant size ), then screw my hose end onto that, so the hose end is totally secure.. I heat the hose with a heat gun a little to make it softer, lubricate inside the hose with oil, and the barb itself, and it takes a reasonable push to engage the hose over the full barb. Then leave to cool normally.

You seem to mention you just shove the hose on with your weight. If so, its highly likely the hose is catching internally, and getting damaged. The push fit stuff is a very tight fit for a reason......so lubrication is required when installing.

#18

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I do use a touch of engine oil (on the end of the hose and on the metal), and put the vise on the ground for the -8an fittings. The -6an fittings are much easier, the vise is on the table. There were no leaks for the first 50 miles.