Camaro and Firebird: LS Engine Camshaft Guide and General Information

The camshaft is considered the brains of an engine. It can either make your engine a winner or a loser. Selecting the right one can be a chore. Understanding how to select the right camshaft can lead you to a much better outcome.

This article applies to Chevrolet Camaro, Pontiac Firebird (1998-2002) and all LSx engines.

The camshaft (or "cam") is a part of the engine that tells the valves when to open, how much to open, how long to stay open, and when to close. Having simple knowledge about how a camshaft works will give you more ammunition to find the right cam for your needs, wants, and desires. Getting a cam which is not suited to your setup can have your car feeling like a dog. Not providing your cam with the suitable support equipment can leave your engine a broken mess, or having one that will not rev properly. It all comes down to having a plan, understanding what your engine needs in a cam, and how the different measurements of a cam affect the aspects of how it will make power.

A cam can be made of cast iron or billet steel. It can be made for flat tappet or roller lifters. Those lifters can be solid or hydraulic. It can have a reduced base circle to allow added room for a stroker engine. It can have a wide LSA, or a fast ramp opening. There are a lot of aspects to the right cam choice. The following article may help you with that choice.

Component Breakdown

Camshaft

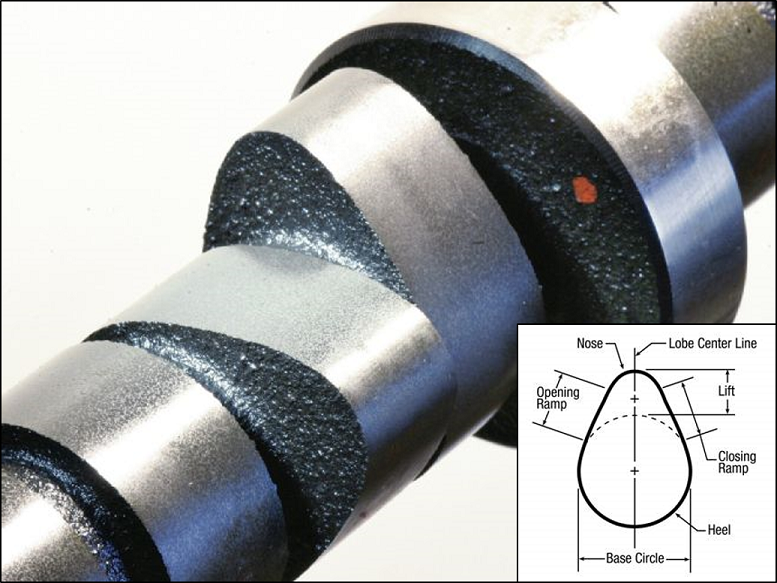

This is your basic LS1 camshaft. It is a roller design, meaning the lifters used on this have a roller base that contacts the cam lobe. There are 16 lobes on this camshaft: one corresponding to each valve in the engine. The five circular, evenly spaced portions are bearing journals. These ride on bearings, which are located in the centerline of the block, just above the crankshaft.

Camshaft Lobe

The cam lobe is what makes the valves react. They are precision timed to perform these acts down to the thousandth of an inch. Lift is determined by the difference of the base circle to the nose at the lobe centerline. A reduced base circle cam will be smaller at the base to allow extra clearance for the bolts on some connecting rods. A lobe can be concentric, where both the opening ramps and closing ramps are exactly the same. Other newer grinds are built with differences here to give exacting characteristics required by the design.

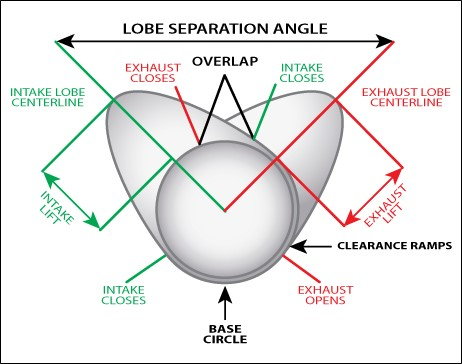

Cam Timing Events

There are several cam timing events that are pertinent to your knowledge of cam shafts. The Lobe Separation Angle (LSA) is the spread in camshaft degrees between the intake centerline and the exhaust centerline. Duration is how long lift is generated at the lobe measured in crankshaft degrees. Overlap is how long both the intake and exhaust valves are open at the same time at the end of the exhaust stroke going into the intake stroke. It, too, is measured in crankshaft degrees. (Lift was described in the Camshaft Lobe description.)

Scheduled Maintenance

Under normal conditions, the cam should last the life of your engine. They will usually fail only if some other part of the valve train fails, such as if a lifter breaks or if the engine loses oil pressure. Solid lifter camshafts require readjustment of the valves at set intervals, but these cams are usually only used in max effort racing engines running at higher rpms. Hydraulic cams are set and forget, adjusting the rocker arms once and then they are usually good for the life of the engine, or until the next time you swap out your cam... whichever comes first.

Common Questions

Why does the LSA matter?

The LSA is largely responsible for the idle quality of an engine. If you have a smaller LSA (narrow), the valve timing tends to seal the cylinder for a longer period of time, but also gives a rough idle quality. A larger LSA (wider) generally gives a smoother idle in street engines.

Can I reuse my stock lifters and springs when I swap cams?

The stock springs are only good for the smaller lift cams, which come stock with the engine. If upgrading much of anything past stock, you'll need to change them out to ones rated for the higher lift of the camshaft. Stock lifters, since they are hydraulic rollers, can be reused if you'd like. It is usually recommended to put in a new set if the old ones have seen a lot of mileage or abuse. A good option for replacement here are the LS7 lifters from GM Performance. They are relatively cheap for what you are getting and can increase the rpm level of the engine before you encounter valve float.

Do I have to pull my heads to change a cam?

No, but you will have to keep the lifters up out of the way or you'll never get the old cam out and the new one back in. The easiest method of doing this is called the JPR lifter tool, though many on the forum make their own. You can purchase either 5/16" or 1/4" rods or dowels and cut them to 26". Use two of them and insert them into the two holes just above and to the sides of the cam bore. There's a trick to these, but nothing too difficult.

What is a good cam for my engine?

This question all depends on your engine and combo. The best answer to this question is do your research and ask your cam manufacturer for advice with regards to your engine setup. Be brutally honest with them as to your setup and be realistic with your goals. Every engine will be different. Everyone has their opinions as to what is a "good" cam and a "bad" cam, so take opinions with a grain of salt and discover for yourself what you want and what you like. Someone else's docile may be your wild.

What are supporting modifications?

Supporting mods are the parts you should have installed on your car before you do a cam swap. Basically, an engine is an air pump: it sucks air in and pushes exhaust out. The better the air flows, the more horsepower your engine will make. If you are using stock parts all around the engine, such as a stock throttle body and exhaust manifolds, you'll not see gains from a cam swap you might otherwise find. Having all of the supporting mods in place before you install the cam will usually bring better results.

Do I have to get my PCM tuned when I do a cam swap?

Getting a tune for your car after a cam swap is a must if you expect to see the horsepower gains and want your engine to run correctly. With most aftermarket cams, the difference in air flow will be dramatic. If your PCM isn't tuned to increase the fuel flow with it, you can be running your engine lean, which will cause detonation and whatever the engine version of thermonuclear meltdown might be. When doing the cam swap, plan to spend the extra money for the tune: your engine will thank you for it!

Common Issues

Valve Float

Valve float happens when an engine is ran past the point where the valve spring can handle the open/closing speed of the valves. This can easily happen when an aftermarket cam is used with stock springs. Follow your cam manufacturer's spring recommendation to alleviate this issue.

(Related Thread: Valve Float? - LS1Tech.com)

Coil Bind

Coil bind occurs when the valve lift exceeds the amount of travel a valve spring will allow. Basically, the spring completely collapses down until all of the coils are touching together, which makes it solid from the spring retainer to the head surface. Valve springs come with coil bind specs, which you'll need to match to the lift of your new cam.

Cam Specs from Mild to Wild

Here is a selection of a few cams with their specs running from mild to wild:

- Cam

- Intake Duration

- Exhaust Duration

- Intake Lift

- Exhaust Lift

- Lobe Separation Angle

- Stock 01-02 T/A

- 196.37

- 208.72

- .464"

- .479"

- 115.92

- Stock 98-00 T/A

- 198.86

- 209.25

- .498"

- .497"

- 119.45

- 02+ LS6

- 204

- 218

- .551"

- .547"

- 117.5

- FMS FM4

- 226

- 226

- .575"

- .575"

- 112

- TSP

- 231

- 237

- .598"

- .595"

- 112

- FM14

- 232

- 234

- .600"

- .600"

- 112

- MS3

- 237

- 242

- .603"

- .609"

- 113+0

- TR Trex

- 242

- 248

- .608"

- .612"

- 110+2

Related Discussions

- Cam Guide - LS1Tech.com

- JPR Lifter Tool? - LS1Tech.com

- Is This a Good Cam for a Mildly Modified LS6 - LS1Tech.com

- Z06 (LS6g) Cam vs. GM Hot Cam - LS1Tech.com

- 5.3 Best Cam Choice - LS1Tech.com

- LT1 Camshaft/Valve Train Selection Guide - LS1Tech.com

- Best Head/Cam combo for LS1 Camaro? - LS1Tech.com

- Best Street Cam for Stock 1999 LS1 M6 Camaro - LS1Tech.com