5 Things to Know About Carbureted LS Motors

For cars that originally came equipped with an LS engine, it would be hard to justify ripping out the EFI system to replace it with an old-school carburetor; however, those that will be performing an LS engine swap into a race car or classic street car may find a carburetor conversion to be a viable alternative to using fuel injection and purchasing/installing all of its associated components.

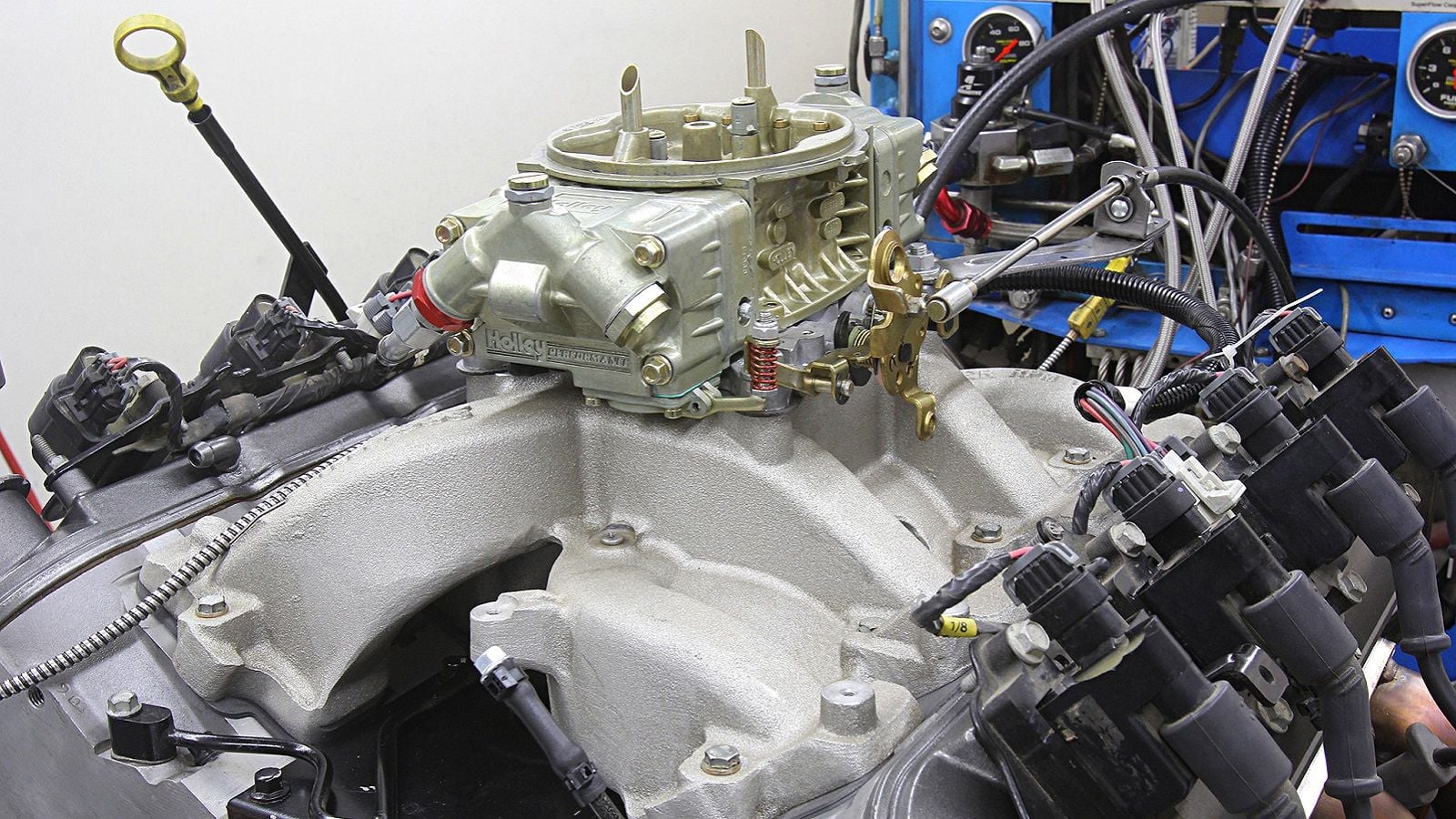

1. Intake Manifold

Converting an LS engine to a carbureted setup is fairly straightforward and requires only a few components to get your motor up and running. To get started, you will need an appropriate intake manifold that can accommodate a carburetor. There are a ton of manifold offerings from GM Performance themselves with their performance intake manifolds as well as companies such as Edelbrock, who have a whole lineup of carb-ready LS manifolds available for any type of build. Dual and single plane intake manifolds are available for both street and race applications, many of which have provisions for EFI if you should ever have the need to switch back to fuel-injection. By identifying which engine you have, its approximate horsepower level, and the usable RPM range in which it will operate can help point you to the correct manifold for your application.

2. Carburetor

If you are going to run a carbureted setup, you can't forget the carburetor itself! Selecting the proper size carburetor is never an exact science, and while many folks will just throw on the biggest, worst carb they can get a hold of, one really needs to evaluate their whole engine package in order to determine which unit will best serve their needs. Decide whether your car will be used on the street or at the strip as street engines have a volumetric efficiency of around 85% while racing engines are closer to 110%, thus requiring more flow. Determining your engine displacement and maximum engine RPM will help to identify the correct carburetor cfm rating. Additionally, it is worth considering what style of intake manifold you are using as a single plane will generally produce more peak power compared to the low-end grunt of the dual-plane unit.

2. Ignition Box

Using a carburetor eliminates the need for a traditional LS wiring harness and accompanying ECM, but will require an ignition box to operate the ignition coils. An LS Ignition Control Box, such as MSD's LS Series Ignition Controller, simply plugs into the camshaft position sensor, crankshaft position sensor, ignition coils, and optional engine coolant temperature sensor to be ready for use. Some ignition boxes (like the MSD unit) have the manifold absolute pressure sensor built into the box itself whereas others require it be plugged into a sensor in the intake manifold. Once connected, these ignition boxes typically have a handful of pre-programed ignition maps for various applications, but also allow for customized timing maps for each cylinder, rev-limiter adjustments, launch control, idle control, etc. In general, these ignition boxes are quite sophisticated devices that have the ability to datalog and give users much more control than could ever be had with a distributor.

3. Fuel Pump

There are a number of different ways to supply fuel to the carburetor with a carb setup, but most agree that fuel pressure should be in the neighborhood of 6.5 psi. Since the LS platform does not have provisions for a mechanical fuel pump, an electric unit must be installed. An in-tank fuel pump is a preferred method of delivering fuel as these came standard on a number of different GM cars from the late 70's through the 80's, but they are also available to be retrofitted into older fuel tanks. Similarly, individuals have successfully been using external fuel pumps mounted in a secure place along the frame rail or similar location. In either case, you are going to want an in-line fuel pressure regulator to dial in the correct fuel pressure for your given application.

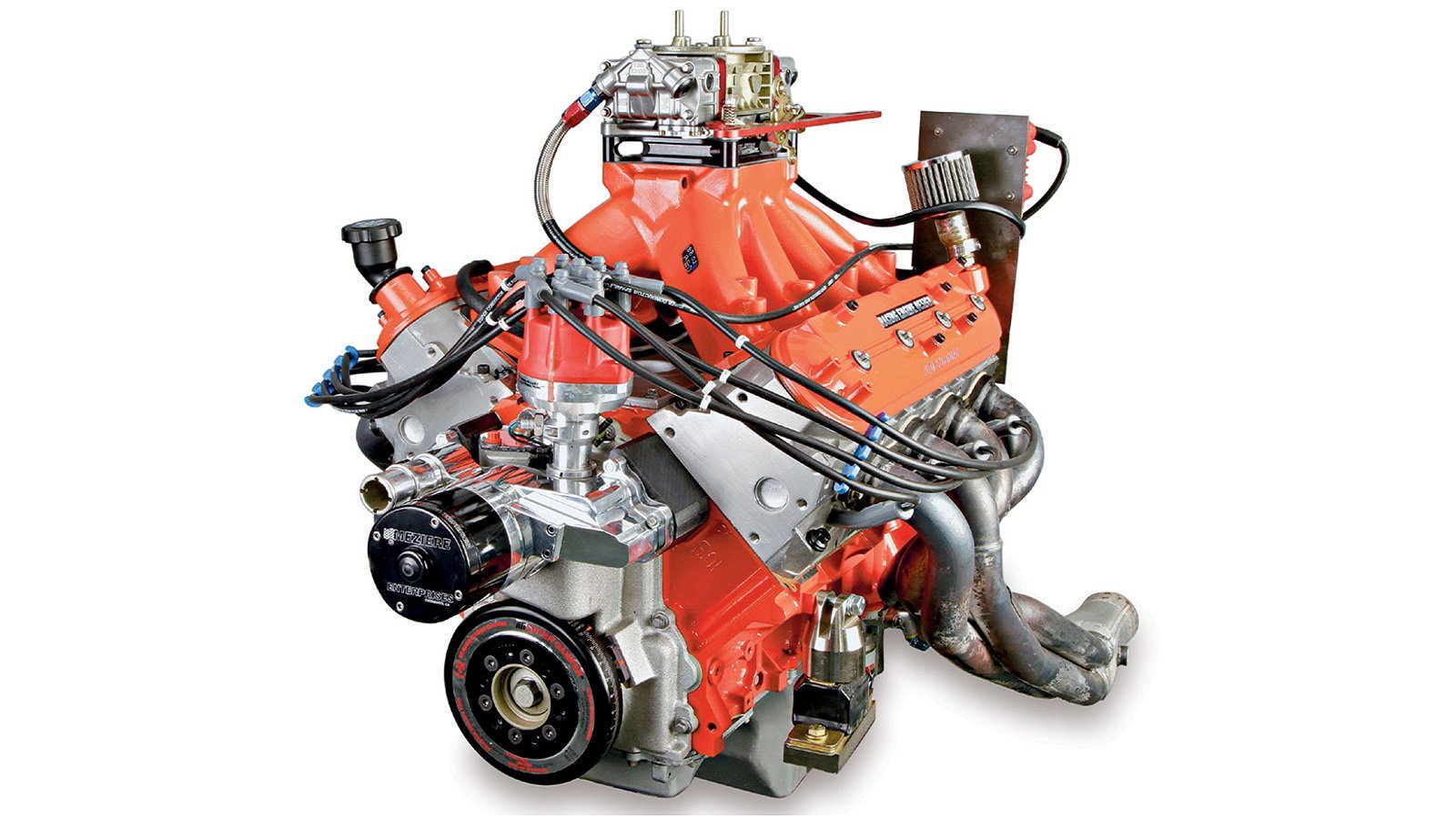

4. Full Retro Distributor Kit

If you are going for a more traditional small block look and/or big power in your classic muscle car, but prefer to use a modern LS powerplant, GM Performance offers an LS Front Distributor Drive Cover that is often packaged as a complete kit by various retailers to eliminates the need for an ECM/ignition control box, coils, and electric fuel pump. The kits typically consist of an aluminum distributor drive cover, HEI distributor, distributor clamp, high-performance spark plug wires, and a mechanical fuel pump of your choice. This kit will change the entire look of the LS engine and will also require a Stewart Components Long Water Pump to achieve the necessary drive spacing. Although many may consider this kit archaic by today's standards, the distributor ignition system has proven to support higher horsepower and RPM levels than both standard and high-performance coil-on-plug setups.

For help with service and maintenance of your car or truck, check out the how-to section of LS1Tech.com