Slideshow: Top Chevy Engine Building Techniques From the Pros

Check out some of the best engine building techniques utilized by the experts themselves!

Engine building at its best!

Gregg Jacobson of PHD Speedcenter exclaims that no matter how much experience you may have with building engines, being able to think outside the box occasionally allows you to step your build up to another level! Some of the best-kept secrets from the top engine builders in the USA have been compiled and explained in the following slides!

Top Dead Center?

A common thread in getting the best results from your engine build is to avoid taking any shortcuts. Gregg stresses that you should check all 8 bores for true top center, not just one!

Avoiding future leaks!

An aspect of an engine build that is often overlooked is the installation of your freeze plugs. It is worth the miniscule amount of extra cash to buy high-quality brass stainless steel freeze plugs for corrosion protection. Use Permatex's The Right Stuff sealer to ensure that you do not have any leaks in the future!

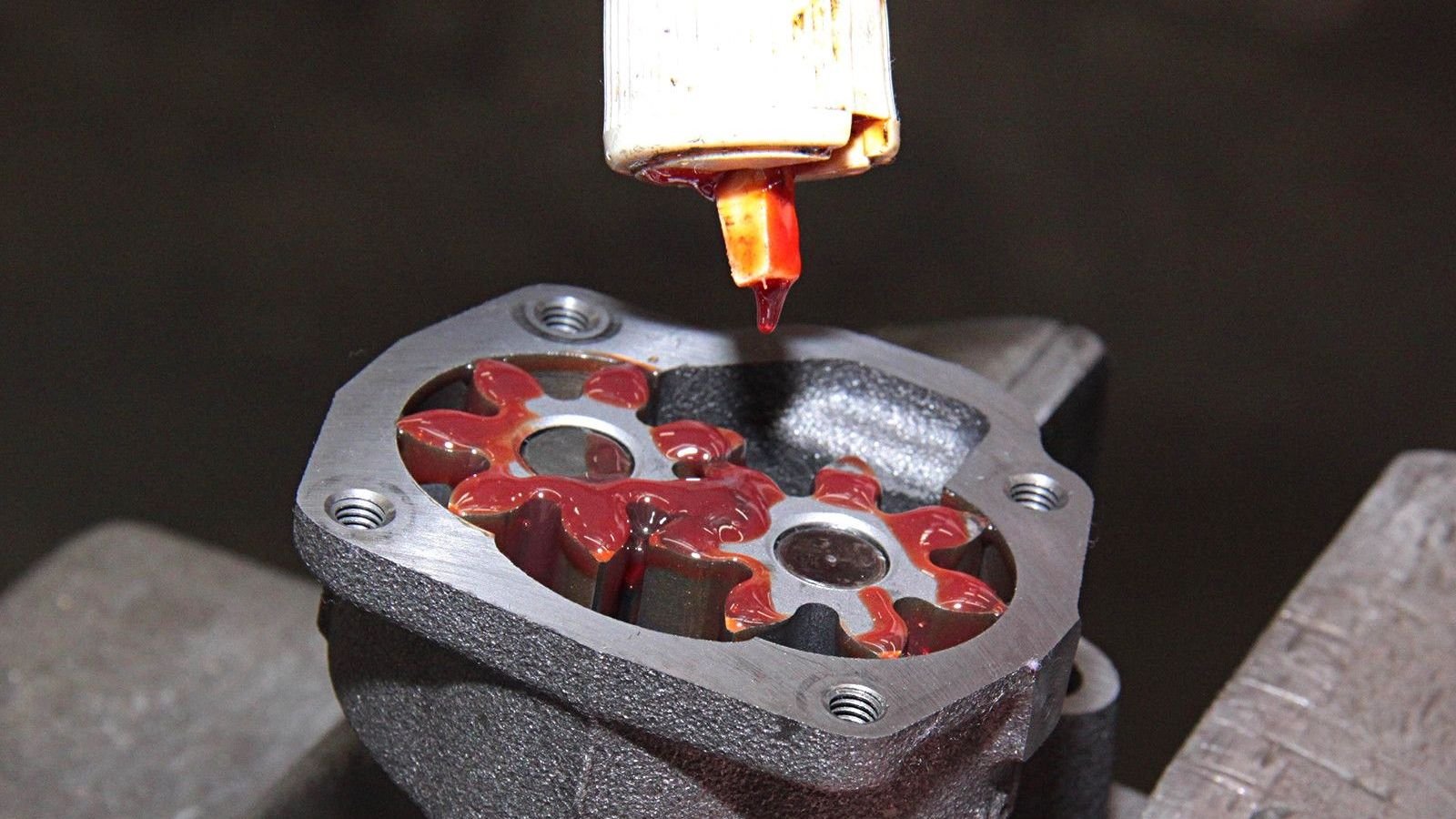

Don't skimp on lubrication!

Always check the clearances on your oil pump even if they have been claimed to be pre-checked. It is also recommended to check the relief valve and spring to make sure they are able to work freely. Lastly, use ARP engine assembly lube on your oil pump shaft and gears to avoid wear during the first startup!

Don't play with your crank endplay!

Checking your crank endplay is essential! Also, don't miss out on checking your connecting rod side clearances, main and rod bearing clearances, oil pump clearances, and camshaft endplay!

Don't trust anyone!

Although most piston rings come pre-gapped, it is essential to check the gap anyway! Piston rings are mass produced and you don't have to end up with a defective unit!

Keep your block clean!

Although most shops use blue shop towels to wipe down their engines, Mast Motorsports from Texas suggests the use of tack rags coated with automatic transmission fluid. They claim that there is a noticeable amount of dirt and debris that a shop towel would miss and you do not want that to end up in your motor!

Strengthen your main caps!

If you are building a race motor, you have no choice but to strengthen your main caps by using studs. This will the main caps nearly bulletproof and will support massive amounts of horsepower.

Discipline with repetition...

Adjusting hydraulic lifters is a relatively standard procedure that requires discipline! Once the lifter is snug with the heel of the lobe, tighten an extra 1/8-1/4-turn for track cars or 1/2-turn for street cars. Make sure you tighten your polylocks and double check all of your adjustments!

Hardened valve seat adjustment...

Although hardened exhaust valve seats are a great upgrade, using stainless steel valves on SBC and BBC applications can be just as good! Make sure the valve seat surface is fresh and drop your valves in!

For help with your maintenance and repair projects, please visit our how-to section in the forum.